78

06/2011 Rev. 7.4

M o d e l 2 0 0 9

06/2011 Rev. 7.4

79

M o d e l 2 0 0 9

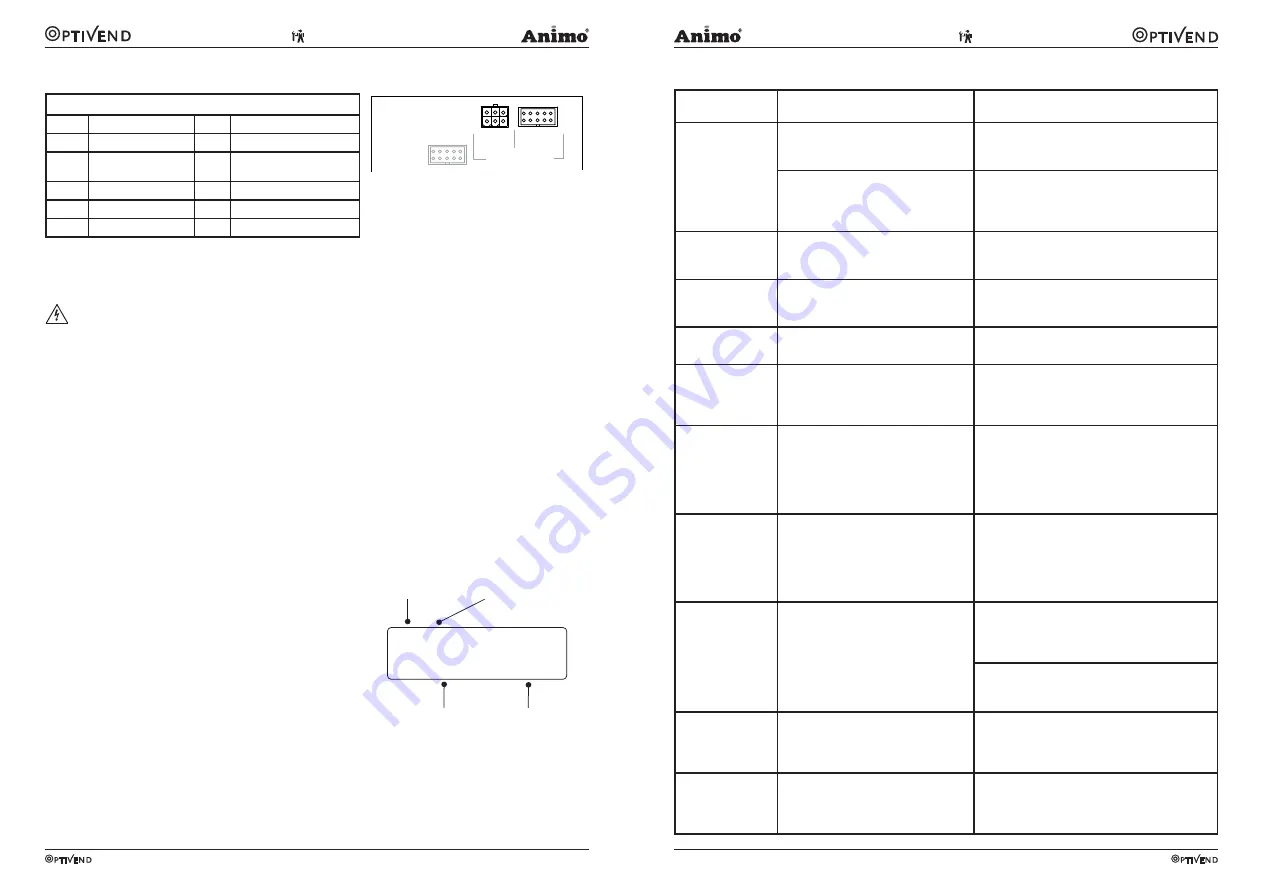

6.4 Main circuit board communication

Communication

Conn

Comments

G13

Coin tester NRI G13

MDB

Coin changer NRI C

2

Please note; MDB signal

should adapted on PC board.

CSI

Future port

RS232

Future port

USB

Future port

7. TROUBLESHOOTING

WARNING

When carrying out repairs and cleaning the device, the plug should always be removed from the

wall socket before the device is opened.

Preface

Before searching for the defect, check that all parts are in their correct position. To do this, remove

the device’s rear plate and check that all printed circuit boards, connectors, wire beams and pipes are

mounted correctly.

After carrying out a general parts inspection, use section 7.3 Troubleshooting analysis to verify the

probable cause of the problem.

#) If the column solution advises replacement of the part concerned, there is always the possibility

that the defect may be caused by another problem. The functioning of the device should therefore be

thoroughly tested to make sure that the defect does not reappear.

7.1 Read log

The last 20 error messages displayed during use are

registered and saved ( g. 16).

To read out these error messages activate the menu item 2.8.

The rst error is the most recent error message.

• The

rst line shows the same error codes listed in

the troubleshooting analysis table (see section 7.3)

• The second line shows the date and time at which the

error message occurred.

7.2 Clear log

Use the Clear log function in service menu 2.9 to clear the log.

G13

MDB

COMMUNICATION

RS232

## $%

&#'(('&##) (#*(#

Number

Trouble code

Date

Time

Fig. 15

Fig. 16

7.3 Troubleshooting

Display

Possible cause

Action

Out of order

Boiler lling

When used for the rst time: boiler

is still empty and is being lled.

No action required. When boiler reaches

the appropriate level, the display will show

'Boiler is heating up'.

During use: boiler is not lling

up or is lling up too slowly. After

60 sec. the display will show 'E3

Level error'.

Check the water pressure, turn the water

supply tap completely open and check the

connection tube for any kinks.

Out of order

Boiler heating

The boiler temperature is

(temporarily) too low because too

much water has been used.

Once the temperature is restored, the

message automatically disappears and the

drink selection buttons are reactivated.

Out of order

Door open

For safety reasons, the machine

automatically switches off if the

door is opened.

The machine can be operated with the door

open by using the door pin (User manual:

section 8.1 ).

Out of order

Stand-by

The machine is on standby.

This function can be set manually or

automatically.

Out of order

E1 Level error

Minimum electrode error: mini-

mum electrode detects no water

but maximum electrode does. Inlet

valve shuts.

Check that the level sensors are function-

ing. See service menu

2.7 Hardware test

.

Switch the device off and on again.

Out of order

E2 Level error

Maximum electrode error:

maximum electrode not reached

within 30 sec. Inlet valve shuts.

Boiler lls up too slowly. Water

pressure has dropped or the water

tank (stand-alone) is empty.

Check the water pressure, turn the water

supply tap completely open and check the

connection tube for any kinks. Switch the

device off and on again.

Out of order

E3 Level error

Electrode error: minimum

electrode not reached within 90

sec. Boiler lls up too slowly

Water pressure has dropped or

the water tank (stand-alone) is

empty.

Check the water pressure, turn the water

supply tap completely open and check the

connection tube for any kinks. Switch the

device off and on again.

Out of order

E6 Boiler temp

Temperature sensor or solid state

relais (SSR) problem.

Check the temperature sensor function in

the service menu

2.7 Hardware test.

Check if SSR switches. Replace if

necessary.

Check if steam detection mounted in the

over ow tube was triggered.

Reset if necessary.

Out of order

E7 Mixer 1 error

Mixer 1 motor stuck. Mixer 1 mo-

tor exit overload (power too high).

Control unit has switched off the

exit.

Check if Mixer 1 is unclean or incorrectly

tted. Clean and/or check whether the rotor

can run freely. Switch the device off and on

again.

Out of order

E8 Mixer 2 error

Mixer 2 motor stuck. Mixer 2 mo-

tor exit overload (power too high).

Control unit has switched off the

exit.

Check if Mixer 2 is unclean or incorrectly

tted. Clean and/or check whether the rotor

can run freely. Switch the device off and on

again.