ANITA ©

MP01700EN_161116

16

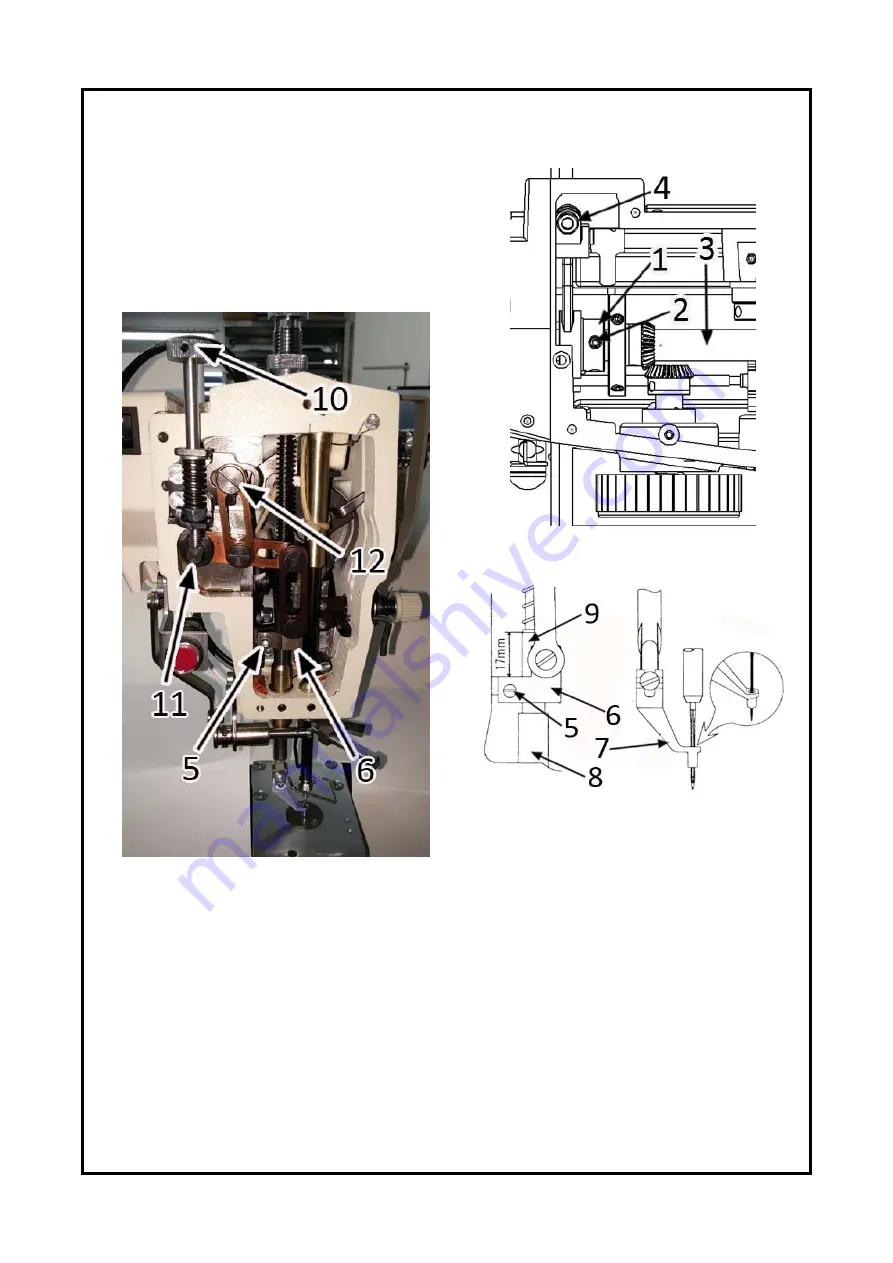

4. ADJUSTMENT OF SUB PRESSER FOOT

A.

Set the needle bar to the lower

reversal point by turning hand wheel.

Loose

n

screws

(

2)

of the eccentric

(1

)

and set this eccentric to the position

whre the screw (2) is in upper

postion.

The eccentric

(1

)

is placed on

the main shaft

(

3), Fig.

26.

Fig.

25

Fig.

2

6

Fig.

27

B.

Set the position of the driver

(6

)

in value 17mm from the edge of presser bar

(

9)

. At

tightening the screw

(

5)

check the position of the needle in the middle of sub

presser foot

(

7), Fig. 25, 27.

C.

Loose

n

safety screw

(

4), Fig.

26 and set the screw

(

12)

to the end right position in

round slot of the lever, Fig.

25.

D.

Set the screw

(11

)

so that there is touch with stopper of hand screw

(10

), Fig.

25.

E.

Set the play between driver of presser bar

(6

)

and bushing of presser bar

(8

)

in value

9mm, Fig.

27. After that tighten the screw

(

4), Fig.

26.

F.

Tighten all srews carefully.

G.

Set needed height of the stroke of sub presser foot

(

7). This is done by moving of the

screw

(

12)

in round slot of the lever, Fig.

25.

www.garudan.cz

Summary of Contents for GARUDAN GPS/G-4032

Page 23: ...ANITA MP01700EN_161116 23 Fig 39 Fig 40 w w w g a r u d a n c z ...

Page 36: ...ANITA MP01700EN_161116 36 w w w g a r u d a n c z ...

Page 40: ...ANITA MP01700EN_161116 4 w w w g a r u d a n c z ...

Page 50: ...ANITA MP01700EN_161116 14 B9 FOR ROTARY HOOK ONLY PRO ROTAČNÍ CHAPAČ w w w g a r u d a n c z ...

Page 68: ...ANITA MP01700EN_161116 32 E9 FOR ROTARY HOOK ONLY PRO ROTAČNÍ CHAPAČ w w w g a r u d a n c z ...

Page 80: ...ANITA MP01700EN_161116 44 I FEED FRAME MECHANISM PODÁVACÍ RÁMEČEK w w w g a r u d a n c z ...

Page 86: ...ANITA MP01700EN_161116 50 L STAND AND TABLE STOJAN A PRACOVNÍ DESKY w w w g a r u d a n c z ...

Page 88: ...ANITA MP01700EN_161116 52 M LUBRICATION PARTS MAZÁNÍ w w w g a r u d a n c z ...

Page 90: ...ANITA MP01700EN_161116 54 M FOR ROTARY HOOK ONLY PRO ROTAČNÍ CHAPAČ w w w g a r u d a n c z ...

Page 92: ...ANITA MP01700EN_161116 56 N AIR CONTROL PARTS PNEUMATICKÉ KOMPONENTY w w w g a r u d a n c z ...

Page 96: ...ANITA MP01700EN_161116 60 R CONTROL BOX ROZVADĚČ w w w g a r u d a n c z ...

Page 98: ...ANITA MP01700EN_161116 62 S1 OPTION VYBAVENÍ NA OBJEDNÁVKU w w w g a r u d a n c z ...

Page 100: ...ANITA MP01700EN_161116 64 S2 OPTION VYBAVENÍ NA OBJEDNÁVKU w w w g a r u d a n c z ...