Operator’s

Manual

Rev

E

4/2/12

pg.

21

Numbered

Notes

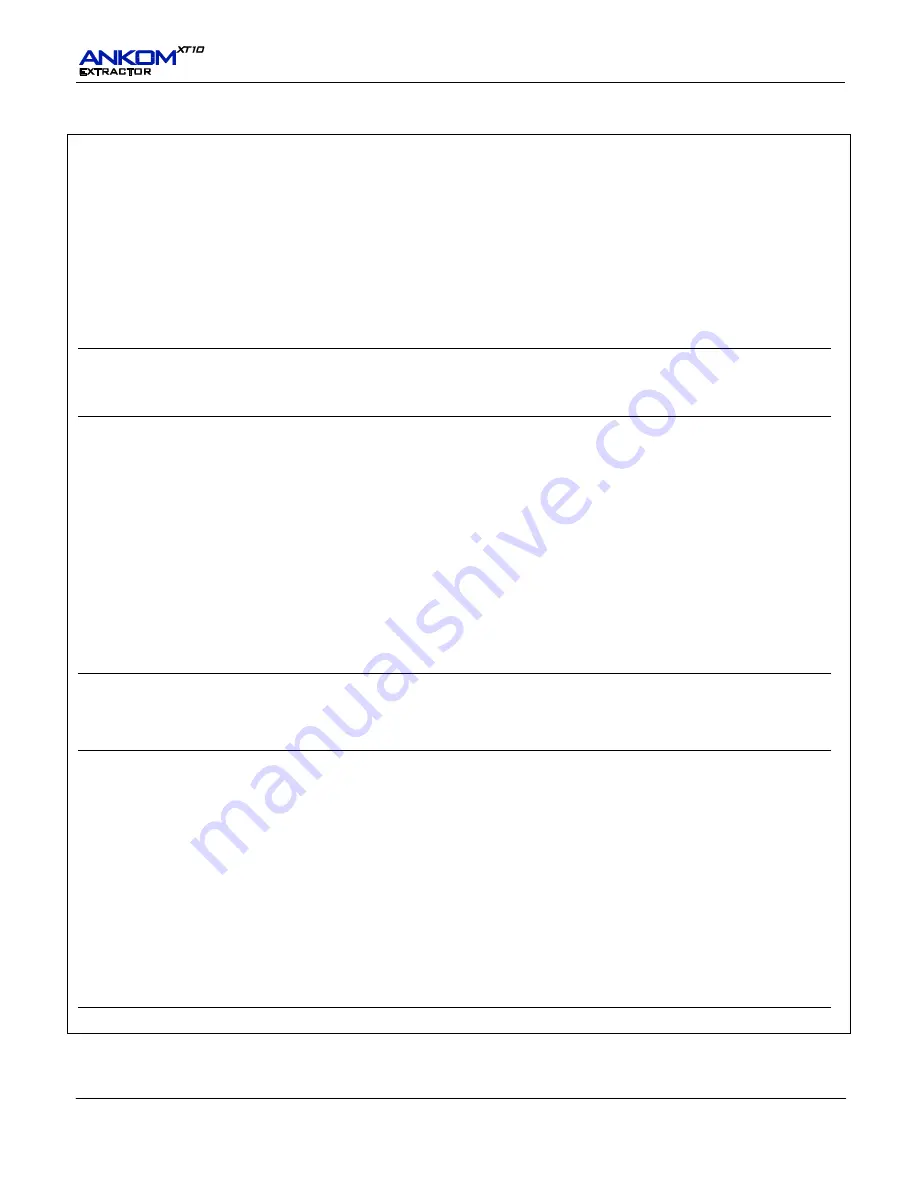

1.

Pre-drying time of the samples in the filter bags can be greatly reduced by using a microwave oven. However, microwave ovens

vary in energy output and samples vary in water and fat composition. You will need to experiment with your microwave oven to

determine the proper conditions for use. Contact ANKOM Technology for further information.

2.

Some samples with large amounts of carbohydrates (starches and cellulose) may bind small quantities of solvent and require

additional post drying. To remove bound solvent, dry at 100°C for 1 – 3 hrs or at 125°C for 30 minutes.

Sample ID

oat

m

eal

bro

w

nie

mix

so

ybean

A

can

ol

a

so

ybean

mea

l

cor

n A

po

ultry

start

er

c

at

tle

fe

ed

pi

g s

tarter

al

fa

lf

a

cat

foo

d

coo

ki

es

bk

ft c

ereal

to

rtilla

c

hip

s

Number of laboratories

12

12

11

9

12

12

11

10

11

11

12

11

12

12

Number of replicates

24

24

22

18

24

24

22

20

22

22

24

22

24

24

Filter Bag Average, % Crude Fat

5.8

8.7

20.9

39.0

1.6

3.3

3.3

3.2

5.6

2.4

6.3

22.7

2.3

19.9

Certified Labs Average

a

5.7

8.7

21.1

39.7

1.6

3.6

3.5

3.0

5.5

2.2

6.2

23.1

2.3

20.0

AOCS Am 2-93 Avg. for Oilseeds

21.9

44.8

3.6

S

r

0.36

0.20

0.35

0.23

0.14

0.31

0.24

0.18

0.20

0.39

0.27

0.20

0.26

0.39

S

R

0.54

0.31

0.63

0.68

0.27

0.42

0.42

0.20

0.28

0.50

0.30

0.20

0.36

0.48

RSD

r

, %

6.2

2.3

1.7

0.6

8.5

9.5

7.3

5.6

3.6

16.1

4.2

0.9

11.4

2.0

RSD

R

, %

9.4

3.5

3.0

1.7

16.3

12.7

12.6

6.1

5.0

20.7

4.7

0.9

15.7

2.4

r

0.99

0.56

0.98

0.65

0.39

0.88

0.68

0.51

0.56

1.08

0.75

0.56

0.72

1.09

R

1.52

0.86

1.76

1.90

0.75

1.18

1.16

0.55

0.78

1.39

0.83

0.56

1.00

1.35

HORRAT

3.05

1.21

1.19

0.76

4.38

3.87

3.77

1.83

1.61

5.92

1.56

0.35

4.45

0.95

Sample ID

dog foo

d

cracke

rs

turk

ey

ham

beef grou

nd

chi

ck

en breast

soyb

ean B

safflo

w

er

pota

to

ch

ips

hot dog

saus

age

corn B

chees

e

cu

rl

s

corn si

la

ge

Number of laboratories

12

10

12

9

11

11

11

9

11

12

11

12

12

12

Number of replicates

24

20

24

18

22

22

22

18

22

24

22

24

24

24

Filter Bag Average, % Crude Fat

6.8

23.8

3.2

11.6

23.8

2.8

19.4

22.5

32.0

39.5

25.7

3.4

30.6

2.3

Certified Labs Average

a

6.9

24.0

3.2

11.3

23.5

2.7

19.7

23.2

32.0

39.0

25.0

3.7

30.5

2.3

AOCS Am 2-93 Avg. for Oilseeds

20.8

24.7

S

r

0.35

0.23

0.21

0.30

0.24

0.33

0.38

0.53

0.48

0.35

0.34

0.39

0.48

0.23

S

R

0.35

0.23

0.34

0.30

0.36

0.33

0.62

0.83

0.52

0.59

0.51

0.41

0.69

0.51

RSD

r

, %

5.23

0.96

6.57

2.59

1.01

11.89

1.97

2.36

1.49

0.89

1.33

11.48

1.59

9.87

RSD

R

, %

5.23

0.96

10.84

2.59

1.49

11.89

3.19

3.69

1.61

1.49

1.98

11.93

2.27

22.45

r

0.99

0.64

0.58

0.84

0.67

0.94

1.07

1.49

1.34

0.98

0.96

1.10

1.36

0.63

R

0.99

0.64

0.96

0.84

0.99

0.94

1.73

2.33

1.45

1.65

1.43

1.14

1.94

1.44

HORRAT

1.74

0.39

3.22

0.94

0.6

3.47

1.25

1.48

0.68

0.65

0.81

3.59

0.95

6.36

a

AOCS Official Methods Ba 3-38, AOAC 920.39 or equivalent

Table 1. A summary of the statistical analysis of the international collaborative study of the Filter Bag Technique for the proposed Official AOCS Method, “Rapid Determination of

Oil/Fat Utilizing High Temperature Solvent Extraction” is presented in this table. Included in the summary is a comparison of the Filter Bag Technique with the results of analysis by

AOCS certified laboratories using official AOCS or AOAC methods

Summary of Contents for XT10

Page 2: ...This page intentionally left blank ...

Page 4: ...This page intentionally left blank ...

Page 25: ...Operator s Manual Rev E 4 2 12 pg 25 Appendix C Electrical Diagram pg 1 of 3 ...

Page 26: ...Operator s Manual pg 26 Rev E 4 2 12 Appendix C Electrical Diagram pg 2 of 3 ...

Page 27: ...Operator s Manual Rev E 4 2 12 pg 27 Appendix C Electrical Diagram pg 3 of 3 ...