Operator’s Manual

pg. 14

Rev 5/21/18

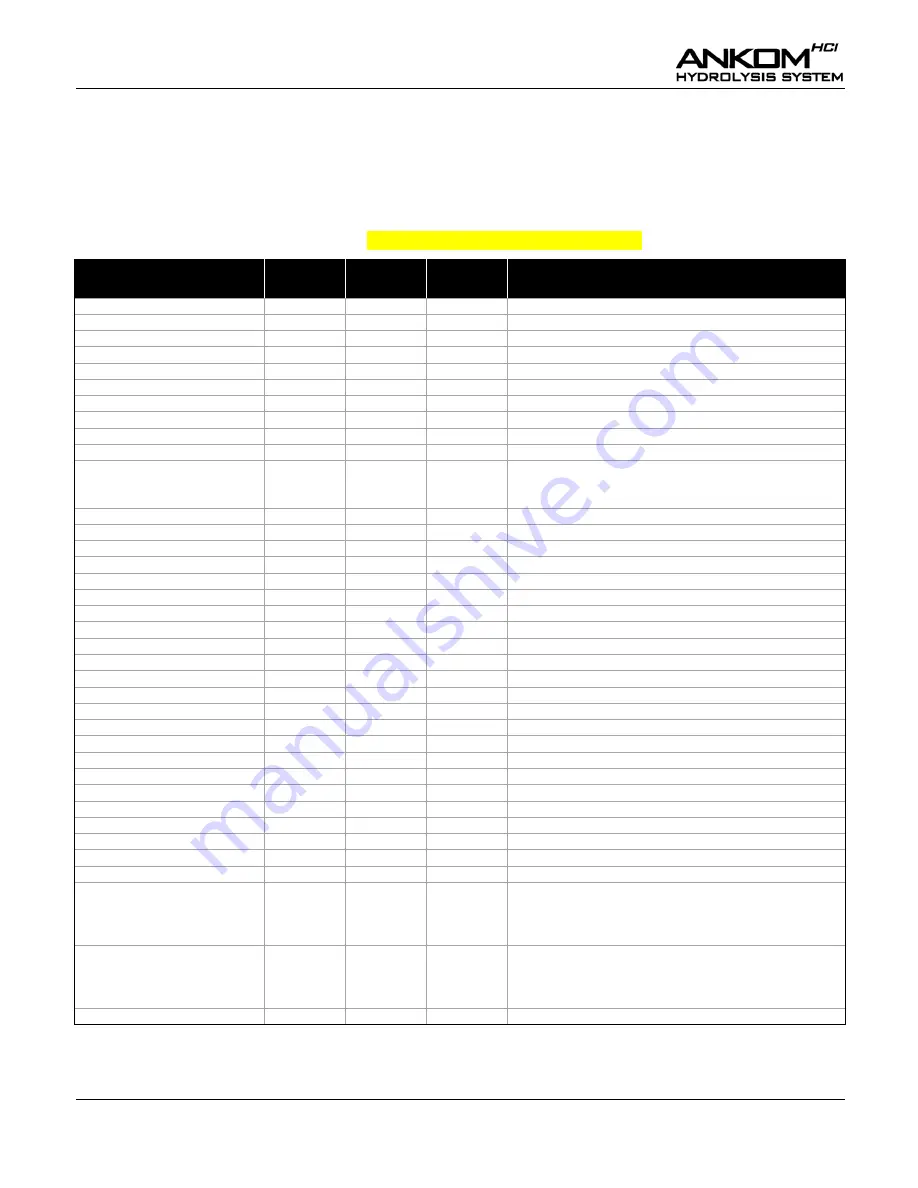

Sample Categorization

For best results, it is important to determine the correct ratio of Diatomaceous Earth (DE) to sample. Before using

your ANKOM

HCl

Hydrolysis System for production testing, it is recommended that you categorize your samples

into types and determine the standard amount of DE needed for each sample type. The following information is

from testing done in the ANKOM lab. This information is meant to help you categorize your own samples.

Sample Categorization Data from ANKOM Lab

(sorted in alphabetical order by Sample Type)

Sample Type

Fat %

DE

Weight

Sample

Weight

Notes

Cheddar Cheese

35%

1.2 g

0.3 g

Cheese Curls

~ 25 %

0.9 g

0.6 g

Chocolate Liquor

> 50 %

1.1 g

0.4 g

Cottage Cheese

< 5 %

0.6 g

0.9 g

Cream Cheese

15 - 35 %

1.0 g

0.5 g

Dried Algae

15 - 20 %

0.8 g

0.7 g

Dried Distillers Grain

< 15 %

0.5 g

1.0 g

Dried Pet Food

5 - 15 %

0.5 g

1.0 g

Feed Mixtures

< 10%

0.3 - 0.4 g

1.1 - 1.2 g

Fish Feed

15%

0.75 g

0.75 g

Forages

2 - 3 %

0.3 g

1.2 g

Most forages are light. Do not allow the mass in the bag to

puff out the sides of the filter bag which will make it more

difficult to completely saturate the sample.

Ground Beef

< 20 %

1.0 g

0.5 g

Ground Beef

> 20 %

1.2 g

0.3 g

Hot Dog

30%

1.2 g

0.3 g

Mayonnaise

75 - 80 %

1.2 g

0.3 g

Meat & Bone Meal

10 - 15 %

0.5 g

1.0 g

Milk Chocolate

25 - 30 %

0.8 g

0.7 g

Milk Powder

15 - 20 %

0.75 g

0.75 g

Milk Replacer

> 30%

0.9 g

0.6 g

Milk Replacer

20 - 30 %

0.75 g

0.75 g

Moist Distillers Grain (syrup)

10 - 12 %

0.7 g

1.0 g

Moist Pet Food (canned)

< 10 %

0.75 g

0.75 g

Mozzarella Cheese

20%

1.0 g

0.5 g

Potato Chips

30 - 40 %

1.2 g

0.3 g

Powdered Non-Dairy Creamer

35%

1.0 g

0.5 g

Pretzels

5%

0.5

1.0 g

Processed Cheese

20 - 25 %

1.0 g

0.5 g

Processed Cheese

> 25 %

1.2 g

0.3 g

Sour Cream

20%

0.8 g

0.7 g

Soybean

20%

0.75 g

0.75 g

Swiss Cheese

30%

1.0 g

0.5 g

Tortilla Chips

25%

0.9 g

0.6 g

Veggie Chips

20%

0.9 g

0.6 g

Whey Powder

2%

0.75 g

0.75 g

Whipping Cream

35%

1.25 g

0.5 g

After adding cream to the filter bag using a pipette (see

milk technique above) and not overflowing the indentation

in the DE, leave the filter bag open and dry it in an oven

for 1 hour at 100-105°C. Seal the bag.

Whole Milk

~ 3%

1.25 g

1.25 g

After adding the DE to the filter bag, press the eraser end

of a pencil into the DE to create an indentation into which

the milk can be added using a pipette. Record the weight

(to make sure DE was not transferred to the pencil) & tare.

Yogurt

1 - 1.5 %

0.75 g

0.75 g

Summary of Contents for XT4

Page 2: ...This page intentionally left blank ...

Page 4: ...This page intentionally left blank ...

Page 12: ...Operator s Manual pg 12 Rev 5 21 18 This page intentionally left blank ...

Page 24: ...Operator s Manual pg 24 Rev 5 21 18 This page intentionally left blank ...

Page 25: ...Operator s Manual Rev 5 21 18 pg 25 Appendix A Electrical Diagram pg 1 of 3 ...

Page 26: ...Operator s Manual pg 26 Rev 5 21 18 Appendix A Electrical Diagram pg 2 of 3 ...

Page 27: ...Operator s Manual Rev 5 21 18 pg 27 Appendix A Electrical Diagram pg 3 of 3 ...