9

Other Cautions

1.

The best condition of using the tool is under 8 hours a day, do not over loaded.

cording to operating frequency and torque loaded, we suggest adding lubricating oils in clutch

per 3-6 months, and kindly contact with distributor when product's maintenance.

2.

Do not attempt to repair or disassemble this cordless screwdriver without authorization. Always

have the device serviced by assigned factory or qualified person in order to have the warranty

effective continually.

3.

ANLIDAR is not responsible for any poor performance or damage caused by customers own

modification of the tool.

4.

It is necessary for the

management to have every operator to read and follow all instructions in

this manual. Do not attempt to repair or disassemble this cordless screwdriver themselves.

5.

Chemicals, Acetone, Benzene, Alcohol, Thinner, Ketone, trichloroethylene, etc shall not be in

contact with the surface of the screwdriver in order to prevent chemical damage.

6.

Please follow instruction carefully and do not drop or shock the screwdriver.

7.

This is an external torque adjustment screwdriver, 0 on the torque adjust ring stands for

minimum torque and 8 for maximum torque. The rated operation time is 1 second / 3 seconds

(ON / OFF). Appropriate fastening frequency is 15 fasteners in each minute. Overrunning may

damage motor due to overheat. Proper amount of screwdriver resting is recommended to prevent

motor overheating.

8.

Not allow to turn the Hi/Lo switch during operation in order to cause system malt-function.

9.

The device will not be able to function again once the OK/NG indicator/signal is not turn off

yet.

10.

When adjusting the torque, for safety purpose should stop the screwdriver completely and set

the switch to neutral position. It could prevent the user from turning the tool on accidentally.

11.

During operation, the switch has been changed accidentally that the device will enable its

self-protecting mode which is power off. Re-start the tool when this happen.

12.

Each operational torque setting, using time and frequency may result in different level of wear

and tear, at higher torque setting and use extensively could accelerate the wearing down of tool.

After one month, the torque is getting reduce gradually at the rate of 2~3% or 3~5 %( max

torque). The longer use of the device, torque reduction will become stable and the users could

measure the torque by a tester on a regular time schedule to check if the torque power still meets

the criteria.

13.

The torque range of MYBT-AS0212/MYBT-AS0212S1 must be measured by the ANLIDAR

torque meter KTM-15.

14.

ANLIDAR cordless screwdriver torque output is generated by clutch mechanism, and it is

applicable to ISO 6789.

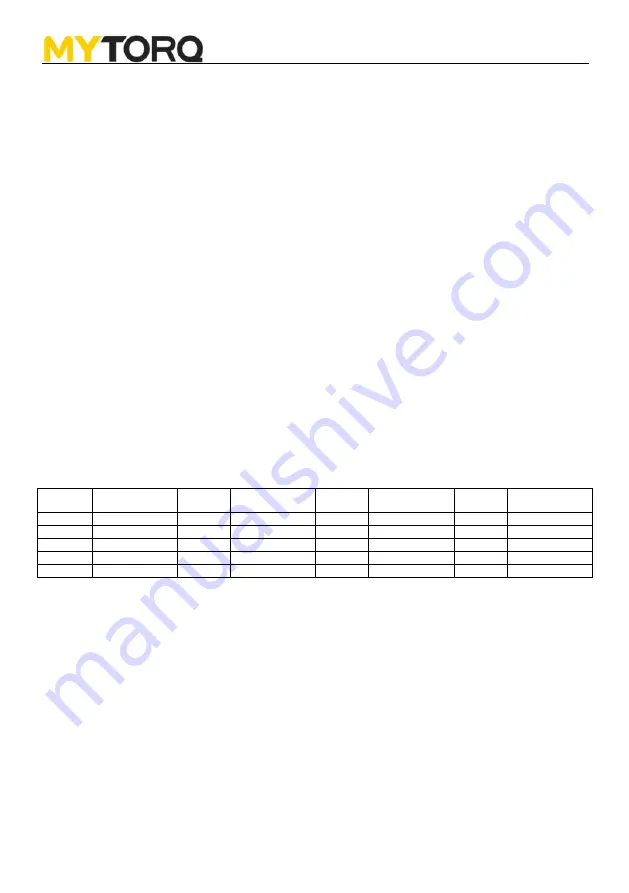

Slow speed

(rpm)

operation

frequency

Slow speed

(rpm)

operation

frequency

Slow speed

(rpm)

operation

frequency

Slow speed

(rpm)

operation

frequency

900

1.0 ON 3.0 OFF

650

1.0 ON 3.0 OFF

450

2.0 ON 5.0 OFF

250

2.0 ON 5.0 OFF

850

1.0 ON 3.0 OFF

600

1.0 ON 3.0 OFF

400

2.0 ON 5.0 OFF

200

2.0 ON 5.0 OFF

800

1.0 ON 3.0 OFF

550

2.0 ON 5.0 OFF

350

2.0 ON 5.0 OFF

150

2.0 ON 5.0 OFF

750

1.0 ON 3.0 OFF

500

2.0 ON 5.0 OFF

300

2.0 ON 5.0 OFF

100

2.0 ON 5.0 OFF

700

1.0 ON 3.0 OFF

Slow speed Duty Cycle Conversion (for reference)

Based on 1000 rpm, 1 second ON/3 seconds OFF. For example, the duty cycle for 350rpm,1000-350=650

,

650/1000%=65%

ON= 1*1.65= 1.65

,

OFF =3*1.65 =4.95 (rounded value) =2 seconds ON / 5 seconds OFF

This tool is intended for a duty cycle of 2.0 sec on, 5.0 sec off.