Safety recommendations for maintenance

Before doing any maintenance work, depressurise the water system and isolate the pump from all en-

ergy sources.

I

When the jobs are done, before restarting the pump, check that no tools, rags or other materials have

been left close to moving parts or in hazardous zones.

Replace any excessively worn components with original parts and use the lubricants recommended by

the manufacturer.

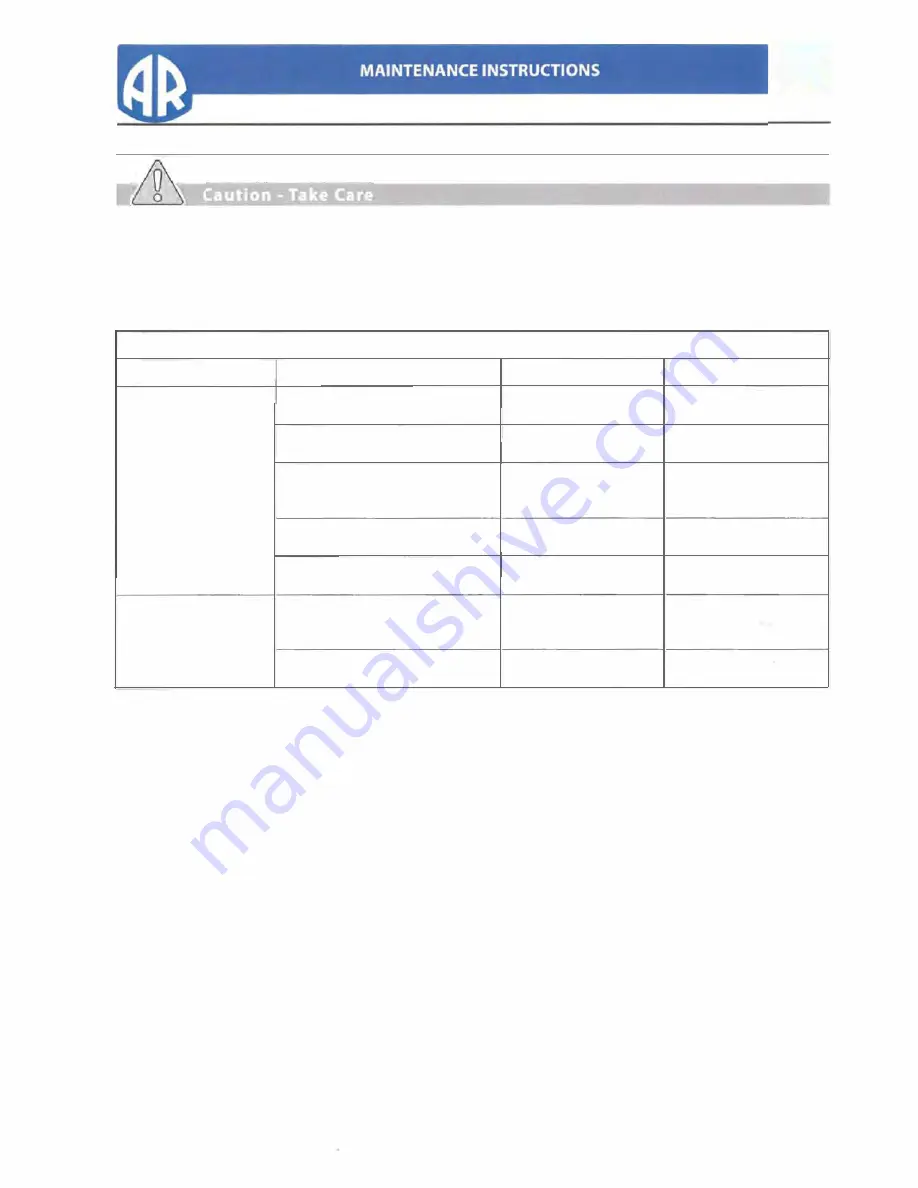

Scheduled maintenance table

Frequency

Component

Procedure

Reference

Filter

Inspect filter cartridge See "Inspecting the

filter"

Pump

Checking the oil level

See "Checking the oil

level"

Connection of pump to power

Inspection

-

Every working day

source (pulley, belt, coupling)

Pump

Inspect mounting

See "Inspecting the

pump mounting"

Pipes and connections

Inspection

See "Inspecting the

connections and pipes"

Pressure accumulator (if in-

Check inflation pres-

See "Checking the

Every 100 working

stalled)

sure

inflation pressure"

hours

Reduction gear (if installed)

Check oil

See "Checking the oil

level"

Dispose of the worn-out components and lubricants in accordance with the relevant statutory require

ments.

Carry out the routine maintenance procedures specified by the manufacturer to keep the pump safe

and performing well.