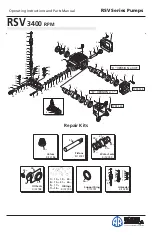

Plunger Pumps

Operating Instructions and Parts Manual

RSV Series Pumps

First Choice When Quality Matters

NORTH

AMERICA

through the pump.

3. Flush the pump with fresh water

before the next use.

4. In freezing conditions failure to

do this may cause internal pump

damage.

5. For long periods of storage in

non-freezing areas the solution

will keep the seals and O-rings

lubricated.

Service Pumps

Servicing the Valves

The inlet and discharge valves in this

series pumps are all the same. The

valves are located under the six 19mm

hex plugs. The inlet valves are located

on the inside portion of the head under

the seal assemblies and the discharge

valves are located on the top row of the

pump head.

Tools required: #8-32x” machine screw

and diagonal pliers, screw driver, 19mm

socket, ratchet, and torque wrench.

Discharge Valve

Removal:

1. Remove the valve

cap. (See Figure 5)

2. Inspect the valve

cap O-ring for any

damage, replace if

necessary.

3. Screw the machine screw

into the hole on top of the valve

cage (approx 1/8”). Using the

diagonal pliers grasp the screw at

the lowest reachable point. Using

the pump head as a base, push

down on the pliers, the

valve will lift out. (See

Figure 6)

4. Use a small probe to

move the poppet up

and down to assure that

the valve is functioning

properly and that no

debris is stuck in the

valve. (See Figure 7)

5. Inspect the valve o-ring

for any damage, replace

if necessary.

Discharge Valve Assembly:

1. Insert the valve

assembly squarely

into the port

pushing it into place

with a deap well

socket (you will feel

the valve assembly

seat). (See Figure 8)

3. Install the

valve cap

and torque

to the proper

specification.

(See Figure 9)

Servicing the Packings/Seals and

Inlet Valves

To access the water seals and inlet

valves for inspection or replacement,

you will first need to remove the head

of the pump.

Tools required: 5mm hex socket,

ratchet, (2) long screwdrivers, channel

lock pliers, mechanics pick and torque

wrench.

Figure 5

Figure 6

Installation (continued)

Figure 7

Figure 9

Figure 8