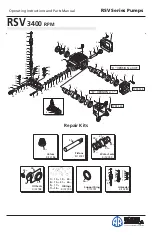

Plunger Pumps

Operating Instructions and Parts Manual

RSV Series Pumps

First Choice When Quality Matters

NORTH

AMERICA

seal (Make sure it

is squarely seated).

(See Figure 21)

4. Installing the low-

pressure seal You

want the open side of the

seal to be pointed toward

the water side of the head (toward

the high-pressure seal) and the flat

side toward the drive end of the

pump.

Place the seal into

the gland at an

angle, with your

finger push the

exposed side of the

seal towards the center

and work the seal into position.

After the seal is in the gland you

can work it into it proper position..

(See Figure 22)

5. Install the retainer

O-ring. (See Figure 23)

6. Squarely seat the

retainer into the head

and push with even

pressure until it snaps

into position. (See

Figure 24)

Inlet Valve Removal:

1. Remove the valve cap.

2. Inspect the valve cap O-ring for any

damage, replace if necessary.

3. Screw the machine screw into

the hole on top of the valve cage

(approx 1/8”). Using the diagonal

pliers grasp the screw at the lowest

reachable point. Using the pump

head as a base, push down on the

pliers, the valve will lift out.

4. Use a small probe to move the

poppet up and down to assure that

the valve is functioning properly

and that no debris is stuck in the

valve.

5. Inspect the valve o-ring for any

damage, replace if necessary.

Inlet Valve Assembly:

1. Insert the valve assembly squarely

into the port pushing it into place

with a deap well socket (you will

feel the valve assembly seat).

3. Install the valve cap and torque to

the proper specification.

Pump Head to Drive End

Installation

1. Turn the crankshaft to align

the plungers as shown. (See

Figure 25)

2. Place the head

evenly onto the

plungers and push

it until it makes

contact with the

drive end of the

pump. (See Figure 26)

3. Torque the head

bolt as shown in the

tightening sequence

diagram.

(See Figure

27 & 28)

Figure 21

Figure 23

Figure 24

Service Pumps (continued)

Figure 22

Figure 25

Figure 26

Figure 27

Figure 28