First Choice When Quality Matters

NORTH

AMERICA

Plunger Pumps

Operating Instructions and Parts Manual

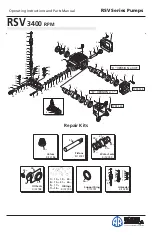

RSV Series Pumps

Oil Change

Change oil after first 50 hours of use.

Then every 500 hours. Refer to parts

breakdown for oil type.

Servicing the Built-in Unloader

and Check Valve

These partw are serviced as assenbled

kits.

Tools required: 3/8” drive ratchet, 19mm

deepwell socket, medium strength

thread locker, needle nose pliers.

Check Valve Removal:

1. Remove the chemical

injector discharge

nipple. Use the needle

nose pliers to lift out

the check valve. (See

Figure 29)

Check Valve Assembly:

1. Place the check valve into the

discharge outlet with the pointed

side going in first (NOTE: older

model pumps have

springs that go into

the hollow portion

of the valve, newer

models do not have

springs.) (See Figure

30)

2. Inspect the o-rings on the injection

nipple, if damaged

replace. Place small

amount of thread locker

on the thread and

tighten. (See Figure 31)

Unloader Removal:

Tools required: 3/8” rachet, 22mm deep

well socket, crescent wrench, small

hammer, 6mm x approximately 8mm or

longer, medium strength thread locker.

Unloader assembly removal:

1. Using the 22mm

socket rotate the

pressure adjusting

cap so both set of

hexes are alligned.

Use screw to remove

the complete unloader

assembly. (See Figure 32)

1. Screw the 6mm bolt into the

unloader piston seat, grab the bolt

with the crescent

wrench just under

the head. Using

the hammer tap

the bottom of the

wrench. The seat will pop

out. (See Figure 33)

Unloader assembly:

1. Piston seat installation

screw the new seat

onto the bolt (NOTE:

the flat side is the

bottom). Push squarly

into the unloader base

and tap into place with

the hammer. (Remove

the bolt) (See Figures 34

& 35)

2. Place a small amount

of thread locker on

the unloader cartride

threads and screw into the

base and tighten.

Figure 30

Figure 31

Figure 29

Figure 35

Figure 34

Figure 32

Figure 33

Service Pumps (continued)