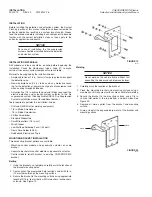

CONTROL MODULE WIRING/DETECTION WIRE ROUTING

(Continued)

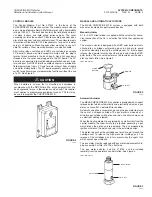

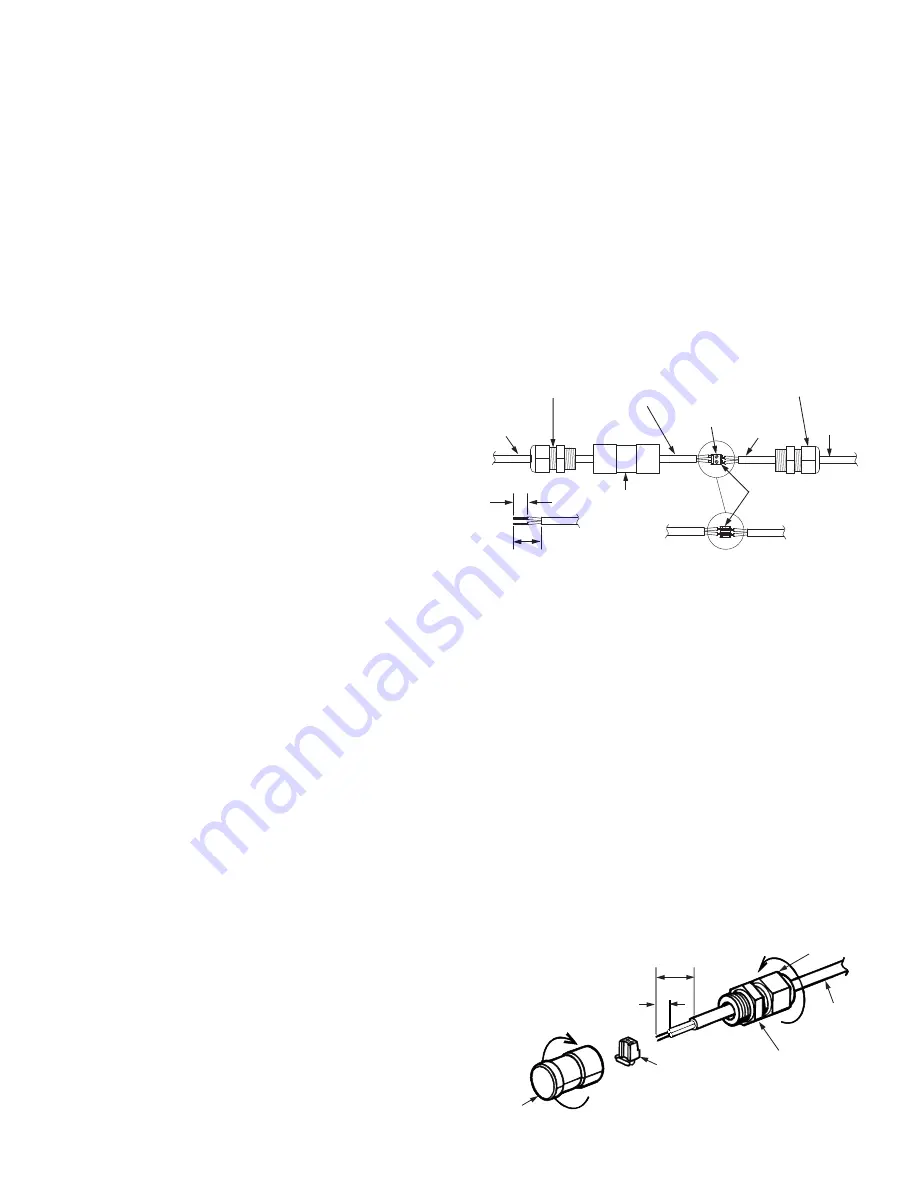

Splicing

If possible, the detection wire should be run in a continuous piece.

However, if splices are required, they must be made using the

following technique. See Figure 26.

The CHECKFIRE In-line Splice Kit, Part No. 428375, is used to

make splices of the linear detection cable. It can also be used to

make the transition splice from non-detection cable to linear

detection cable.

The splice kit consists of Part No. 426783 plastic splice bodies,

Part No. 423546 plastic water-tight strain reliefs, and Part No.

433284 splice block. Each kit contains enough of each component

to make up ten (10) complete assemblies.

When used with the proper size smooth round jacketed cable, the

splice will provide an IEC IP68 level of protection against water

intrusion. Additional protection is provided by filling the splice body

cavity with Dow Corning 737 sealant (or equal), and also applying

the sealant to the threaded connections of the strain reliefs during

assembly.

Specifications:

• Allowable cable outside diameter: 0.08 in. (2 mm) minimum,

0.24 in. (6.1 mm) maximum

• Acceptable wire size: 22 AWG (0.0253 in. (0.6 mm) diameter) to

18 AWG (0.0403 in. (1 mm) diameter)

• UL Recognized, CSA Certified Strain Reliefs

To properly make a detection circuit splice, the following steps

should be completed:

1. Remove 3/4 in. (19 mm) of the wire outer jacket, exposing the

internal Mylar wrap.

2. Remove 3/4 in. (19 mm) of the wire mylar wrap, being careful

not to damage the internal heat sensitive conductors.

3. Strip 3/8 in. (10 mm) of heat sensitive insulation from the inner

conductors, leaving 3/8 in. (10 mm) of insulation on each.

4. Loosen the compression nut of the strain relief assembly and

slide the assembly over the end of the wire as shown in

Figure 26. On the same wire end, slide the splice body onto

the wire.

5. On the opposite wire, repeat Steps 1-3, then loosen the

compression nut on another strain relief assembly and slide

that assembly onto the wire.

6. Insert splice block on end of one set of exposed wires. Wires

must be inserted far enough into slice block to protrude out

the opposite side.

7. Insert other set of exposed detection wire through the oppo-

site side of the splice block, again making certain that they

protrude out the opposite side.

8. Tighten screws on splice block.

9. Once splice block assembly is completed on both sets of wire

ends, apply Dow Corning 737 sealant (or equal) to strain relief

threads going into the splice body.

10. Securely tighten the strain relief into the splice body.

Note:

Do

not tighten compression nut unto wire at this time.

11. Slide splice body assembly near splice block. Fill splice body

approximately 3/4 full with Dow Corning 737 sealant and pull

splice body assembly over splice block so slice block is

located approximately half way inside splice body. This oper-

ation should result in the splice block being enclosed in the

sealant.

12. Fill remainder of splice body cavity with the sealant.

13. Apply Dow Corning 737 sealant to the thread on the unat-

tached strain relief lock nut and thread this strain relief assem-

bly unto the splice body.

14. With a wrench on both strain relief locks, simultaneously

tighten both ends.

15. Complete assembly operation by securely tightening the

strain relief onto the detection wire.

FIGURE 26

007045

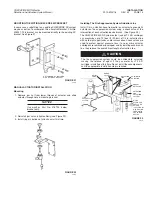

Wiring

Once the detection wire has been routed and secured in the

hazard area, complete the following steps:

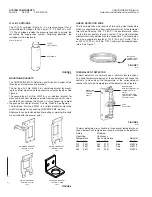

1. Install an end of line resistor assembly, Part No. 426520, to

the far end of the detection wire. To properly attach the E.O.L.

Resistor assembly, complete the following steps (see Figure

26a):

a. Strip 1 in. (25 mm) of outer jacket off the linear detection

wire or the spot detection cable.

b. Strip 1/4 in. (6 mm) of insulation off the two inernal wires.

c. Loosen the lock nut on the strain relief connector and slide

both lock nut and connector over end of wire.

d. Loosen screws on terminal block, insert bare wires, and

securely tighten screws.

e. Apply a small amount of Dow Corning 737 sealant or equal

on male threads of strain relief connector.

f. Screw E.O.L. cap to strain relief connector.

g. Tighten lock nut onto detection wire.

h. Secure E.O.L. cap to support device (by others) using a

nylon cable tie, Part No. 56991.

FIGURE 26a

002774

INSTALLATION

2012-MAY-18 REV. 02 PAGE 15

CHECKFIRE MP-N Electric

Detection and Actuation System Manual

LINEAR

DETECTION

WIRE

STRAIN RELIEF,

PART NO. 423546

SPLICE

BLOCK,

PART NO.

433284

OVERLAP

CONDUCTORS

UNDER SCREW

TERMINALS

LINEAR

DETECTION

WIRE

LINEAR

DETECTION

WIRE

LINEAR

DETECTION

WIRE

STRAIN RELIEF,

PART NO. 423546

SPLICE BODY,

PART NO. 426783

3/4 IN.

(19 mm)

3/8 IN.

(10 mm)

TERMINAL BLOCK

WITH 4.7 OHM

RESISTOR

STRAIN RELIEF

CONNECTOR

1/4 IN.

(6 mm)

INSTALLED

DETECTION

WIRE

LOCK

NUT

E.O.L.

CAP

1 IN.

(25 mm)