INSPECTION AND MAINTENANCE

To ensure the CHECKFIRE MP-N Electric Detection and Actu a tion

System will operate as intended, proper inspection and mainte-

nance procedures must be performed at the specified intervals.

DAILY INSPECTIONS

The equipment operator must check the system daily by visually

verifying that the GREEN power LED is flashing and no other LED

is illuminated. Also, no audio alarm should be sounding. If any

other conditions exist, contact the local authorized ANSUL distrib-

utor or whoever has been trained and authorized by ANSUL to

perform inspection and maintenance checks.

MAINTENANCE

To give maximum assurance that the system will operate as

intended, maintenance must be performed at six-month intervals

or sooner depending on the operating environment. Maintenance

should be performed by an authorized ANSUL distributor or

someone who has been trained and authorized by ANSUL to

perform maintenance checks.

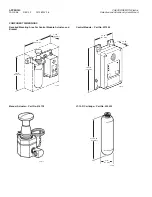

1. Check all mounting bolts for tightness or corrosion.

2.

Remove

the LT-10-R cartridge from the manual/automatic

actuator, install shipping cap, and set aside in a safe location.

Cartridge must be removed before continuing with the following

steps or accidental system actuation will take place when gas

motor is actuated.

3. Remove the connector lead from the gas motor.

4. Hand tighten the lead connector onto the test module, Part

No. 423541.

5. Inspect the detection and interconnecting wiring as follows:

a. Check for wear due to vibration at penetrations, around

corners, etc.

b. Check for damage from direct impact or other abuse.

c. Check for tightness at points of securement. Make certain

fasteners have not come loose which would allow the wire

to sag or shift.

6. If thermal detectors are used, check that they are securely

mounted and have not corroded or been damaged.

NOTICE

If a vehicle shutdown device is installed,

the vehicle should be running at this time

to verify that the device is functioning

properly.

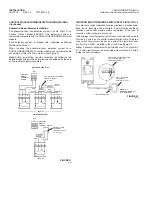

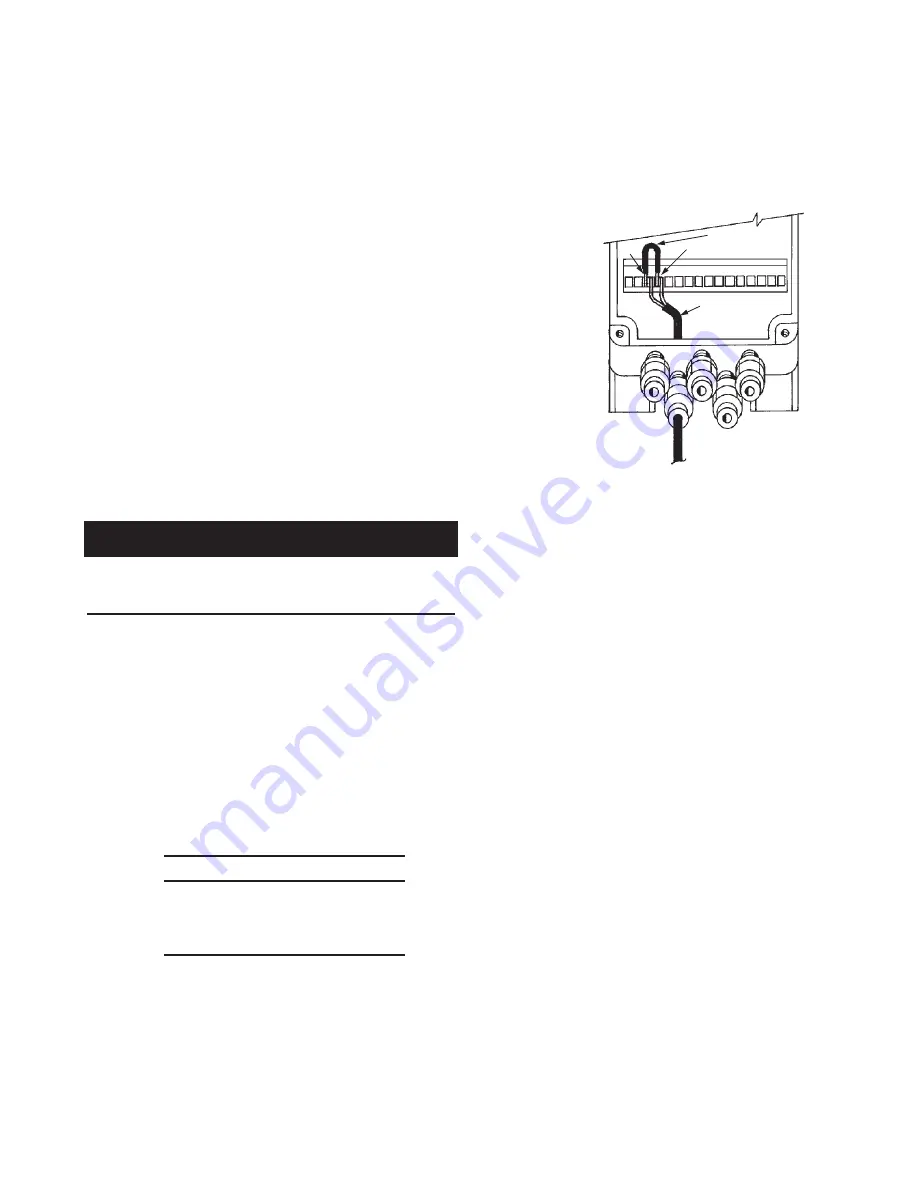

7. Before conducting the functional test, remove the module

cover and install the extender cable(s). Then, using a digital

Ohmmeter, measure the resistance between terminals 3 and

4 with the detection wire connected. The resistance value

should read approximately 4.7K ohms. This will verify the

circuit is intact and the end-of-line resistor is connected.

8.

Check first time delay – Alarm to Shutdown

– Using a short

length of insulated wire stripped at both ends, hold one end of

the wire to Terminal 3 and the other end to Terminal 4 on the

control module. See Figure 43.

FIGURE 43

002770

Using a jumper wire, temporarily short Terminals 3 and 4,

removing the jumper before the end of the first time delay

cycle. This will test the non-latching function of the first time

delay. While the wire is being held in place, the RED Alarm

LED will pulse and the sounder will operate.

Remove the jumper wire. At this point, both the RED Alarm

LED and the sounder will stop pulsing and the first time delay

will recycle back to zero. The control module will return to

normal with only the GREEN Power LED on.

9.

Check second time delay – Shutdown to Discharge

–

Once again, hold the wire on Terminals 3 and 4. The RED

Alarm LED and the Audio Alarm will pulse. Hold the wire on

the terminals for a period longer than what the first time delay

is set up for. While holding the wire on the terminals, time the

length of the first time delay to verify that it is the same as

what it was set for.

At the end of the first time delay cycle, the pulse rate of the

Audio Alarm will change. This will start the cycle of the second

time delay. At this point, the timing cycle is latched, and the

wire jumper need not be held on the terminals. Also at this

point, the shutdown relay will operate, causing the vehicle to

shutdown.

Time the length of the second time delay to confirm that it is

the same as what has been set.

When the second time delay cycle is completed, the release

circuit will activate causing the GREEN LED on the test

module to illuminate.

10. Reset test module by pressing the reset button on the tester.

Do not disconnect test module at this time.

11. After making sure that the control module is reset and operat-

ing in a normal non-alarm non-trouble mode, remove the gas

motor actuator cable from the tester and connect to gas motor

assembly.

Note: For proper assembly, the new gas motor

must be threaded fully, 6 threads, onto the actuator body

and properly secured with the allen head set screw.

!

CAUTION

INSPECTION AND MAINTENANCE

2012-MAY-18 REV. 02 PAGE 27

CHECKFIRE MP-N Electric

Detection and Actuation System Manual

DETECTION CIRCUIT

TERMINALS 3 AND 4

4

DETECTION

CIRCUIT

WIRING

JUMPER

3