Correct maintenance will help to ensure the life and dependable

operation of the water oscillating monitor. The following proce-

dures should be conducted every six months or more frequently if

desired.

1. Perform monitor testing procedures as indicated on Page 6.

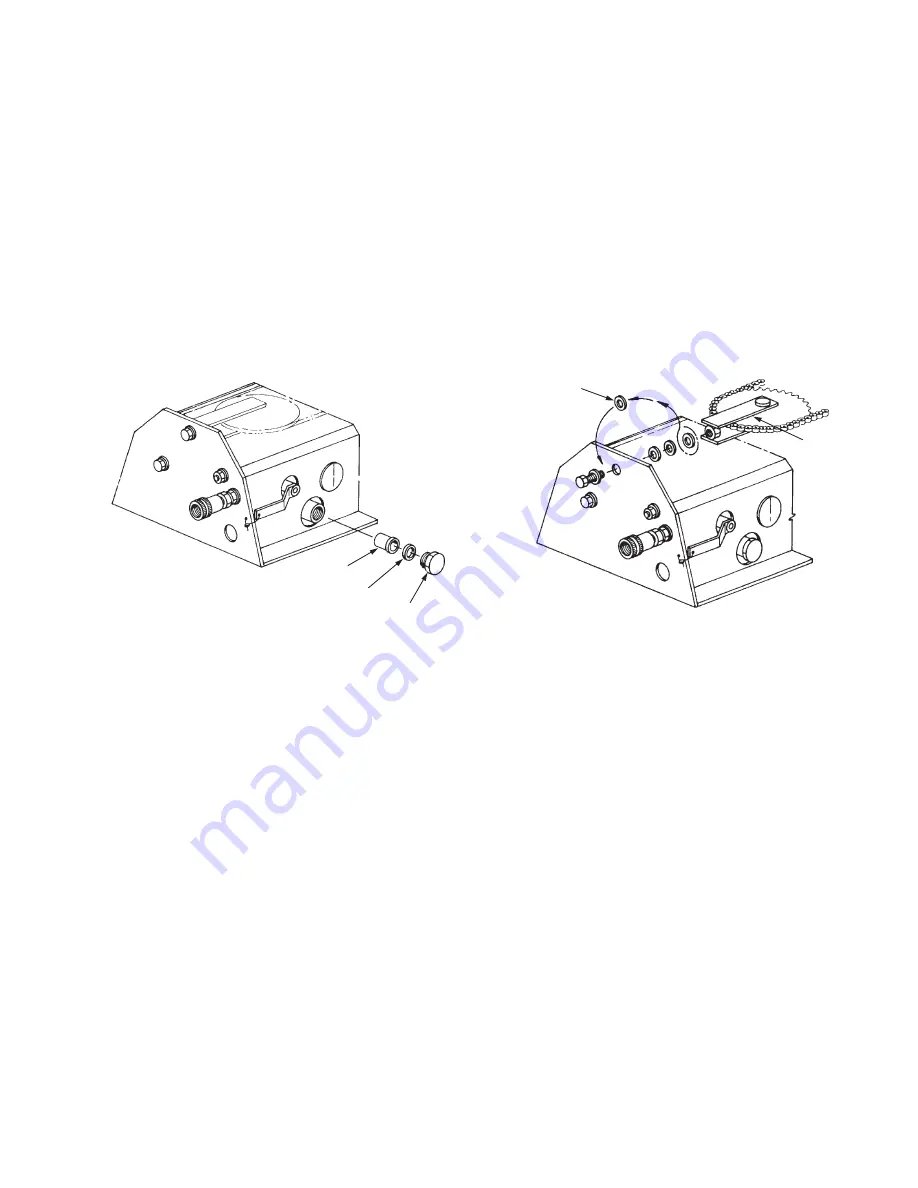

2. Clean the filter element by completing the following steps.

(See Figure 5.)

a. Unscrew 1 1/4 in. hex plug on right side of oscillating mech-

anism enclosure.

b. Remove gasket and bronze filter element from opening.

c. Clean any foreign particles from filter element using pres-

surized air or water.

d. Reinstall filter element and gasket. Replace hex plug.

FIGURE 5

006010

3. Check that flange bolts are tight and monitor supports are

secure.

4. Manually rotate monitor to line up grease fittings with access

holes in left side of enclosure. (See Figure 4.) Lubricate spar-

ingly with monolithium grease.

5. Lubricate monitor base couplings and elevation couplings with

monolithium grease. (To grease the WOM-3 monitor base

coupling, the monitor must be rotated approximately 90° to

the right so that grease fitting can be reached through access

hole at side of enclosure.) See Figures 1, 2, and 4 for grease

fitting locations.

6. Remove cover from oscillating mechanism enclosure.

7. If chain requires tightening, complete the following steps and

refer to Figure 6.

a. Unscrew bolt that secures clevis assembly to enclosure

chassis.

b. Remove one of the washers between clevis assembly and

chassis.

c. Place the washer (that was removed) between the bolt

head and the chassis assembly to maintain clearance

between end of bolt and chain sprocket.

d. Reattach clevis assembly to chassis making certain

washers are in place.

e. Recheck for clearance between end of bolt and chain

sprocket.

FIGURE 6

006011

8. Lubricate chain and sprockets with monolithium grease.

9. Reinstall cover onto oscillating mechanism enclosure.

10. Record date of maintenance examination in accordance with

the authority having jurisdiction.

MAINTENANCE

Page 9

FILTER

ELEMENT

HEX

PLUG

GASKET

CLEVIS

ASSEMBLY

MOVE WASHER

TO TIGHTEN

CHAIN