Antaira Technologies - Industrial Ethernet Switches

LNX-1600-E Series - Hardware Manual - v1.0

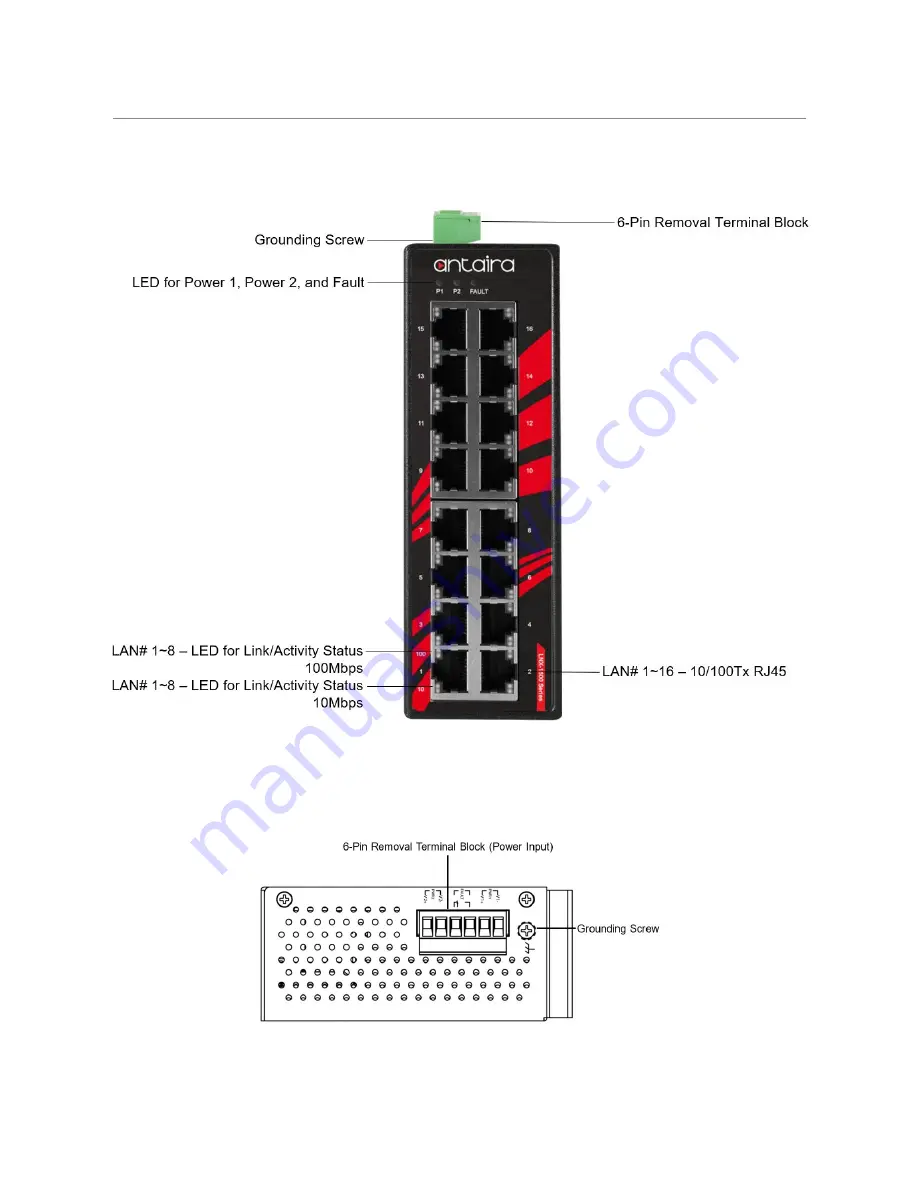

2.2 Front View Panel

Figure 2.2, below, shows the front panel of the product series:

Figure 2.2 - Front View Panel

2.3 Top View Panel

Figure 2.3, below, shows the top panel of the product series:

Figure 2.3 - Top View Panel

4