7.2.3 - How to pair the pedal with the unit

1 - Press on the pedal lever.

2 - Press the 3 green buttons on the screen at the same time.

3 - The logo

flashes until the pairing is complete (time to achieve pairing = about 30 sec)

4 - Press the 2 end buttons on the pedal.

5 - A beep at the console confirms the pairing : the logo

disappears and the logo

is

displayed.

→

If after all these actions, the pictogram remains lit, see the section “Anomalies and errors”

7.2.4 - How to place the pedal in extended standby.

If you don’t plan to use your motor for an extended period of time (> 30 days), or you wish to

transport it by air, placing the pedal in extended standby mode is recommended.

To do so, just press on the 3 pedal buttons simultaneously.

The persistent display of the symbol

on the screen confirms that the pedal is on standby.

To leave standby mode, just press on the pedal lever (see start of section 7.2.1).

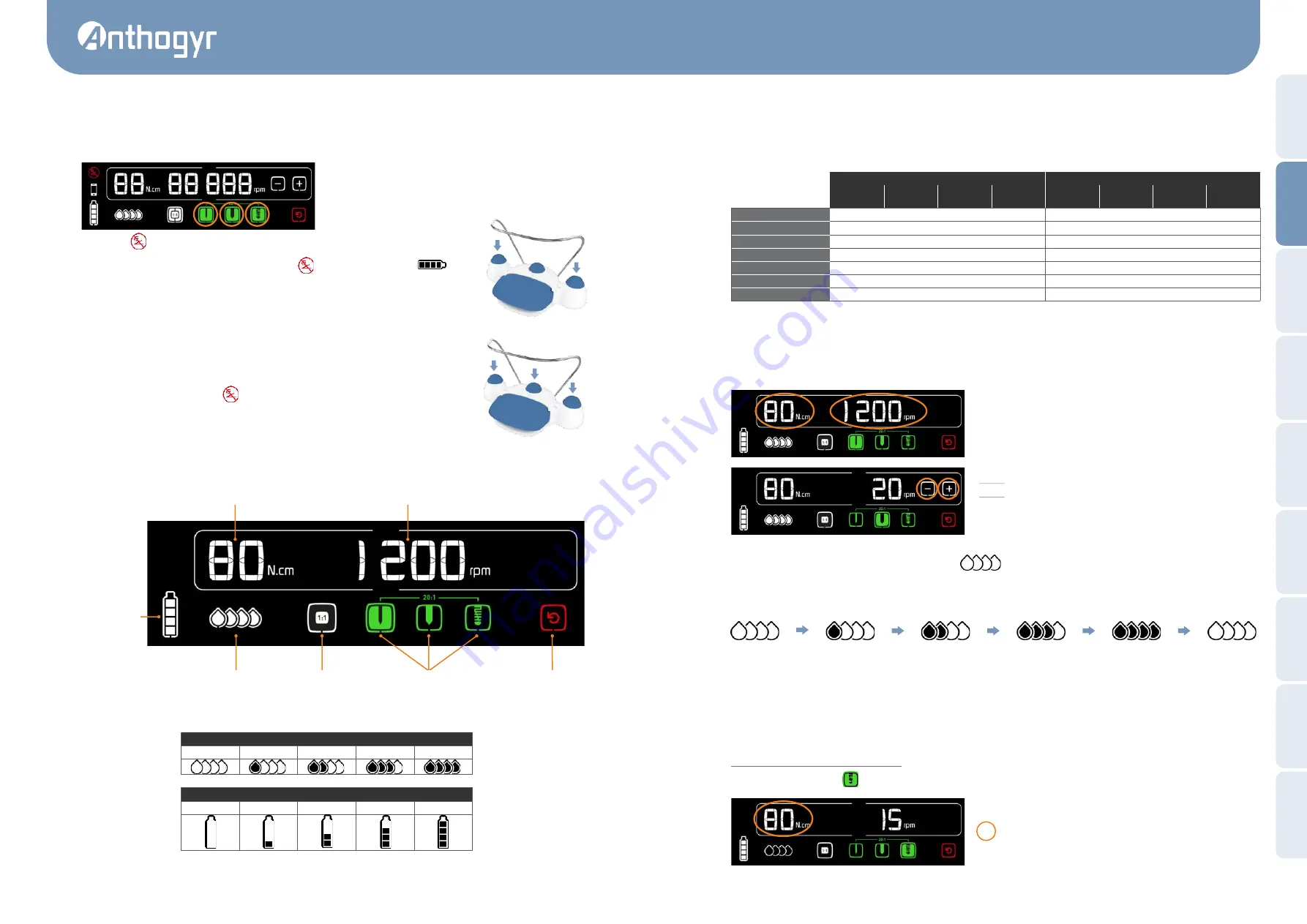

8.1. DEFINITION OF THE DISPLAY

* the coloured square indicates the current program.

8. USE

Programmed maximum

torque (N-cm)

Programmed maximum

speed (rpm)

Charge level of the

pedal battery

Reverse operation

Implantology sequence 20 :1

Drilling / tapping / screwing

Program 1 :1

Irrigation flow rate

Pump

0%

25%

50%

75%

100%

Battery

0%

25%

50%

75%

100%

*

a

®

-

EN -

USER GUIDE

Fr

an

çais

Engli

sh

D

eu

tsc

h

Esp

añ

ol

Ita

li

an

o

Portu

gu

ês

Ne

d

erl

an

d

s

中国的

رع

8.2 PARAMETERS OF PROGRAMS (FACTORY SETTING)

To select a program on the screen, press on the pictogram of the selected program. For navigation to the pedal between the implantology

sequence programs, see para. 8.5.

At the startup, the program "drilling" is active. The program parameters can be changed by following the instructions given below.

* The range of setting from 5 to 80 N-cm. These values are valid only for the contra-angles of the MontBlanc

®

Implant series (10400X-XL / 16400X-XL).

With

these contra-angles, the accuracy of torque is ± 10% for the range from 5 to 80 N.cm.

8.3. SETTING THE VALUES OF SPEED / TORQUE / FLOW RATE

8.3.1 - Setting the rotation speed and the maximum torque

1 - Pressing on the parameter to be changed (speed or torque).

2 - The parameter starts flashing and the b/- appear.

3 - Adjust the value of the parameter with the b or

–

.

4 - Press on the parameter to validate. The parameter stops flashing.

5 - The parameter automatically stops flashing after 5 seconds and the

set value is saved.

NOTE 1 : Value of the parameter is saved permanently for the program.

NOTE 2 : You cannot operate the pedal during the setting of the parameters.

8.3.2 - Setting the irrigation flow rate

For setting the irrigation flow rate, press on the pictogram

Each press increases the flow rate by 25% (display of an additional drop).

At 100%, an additional press makes the irrigation flow rate 0%.

To cut off the irrigation and reset to a given flow rate, use the ON / OFF function of the pedal. (See paragraph 8.5).

8.4. DISPLAY OF THE LAST TORQUE REACHED

The XPERT UNIT

®

motor allows you to validate the tightening torques to be saved. These torques will be exported with the mobile app

XPERT UNIT

®

and used on the web portal.

Displaying and saving the tightening torques

In tightening mode, (button

lit up) when the motor has stopped, the torque displayed is the maximum torque programmed (Screen

A).

In normal mode

In reverse mode

20 :1

Drilling

20 :1

Tapping

20 :1

Screwing

Ratio 1 :1

20 :1

Drilling

20 :1

Tapping

20 :1

Screwing

Ratio 1 :1

Speed (rpm)

1200

20

15

40 000

2000

40

30

15 000

Torque * (N.cm)

80

80

80

80

80

80

80

80

Direction of rotation

right

right

right

right

left

left

left

left

Pump

100%

100%

0%

100%

0%

0%

0%

0%

Display of the torque

NO

YES

YES

NO

NO

YES

YES

NO

Display of the speed

YES

YES

YES

YES

YES

YES

YES

YES

Beep

/

/

/

/

YES

YES

YES

YES

0%

Press

25%

Press

50%

Press

75%

Press

100%

Press

0%

A

Summary of Contents for Xpert Unit

Page 1: ...bcdef ghij EN User manual ...