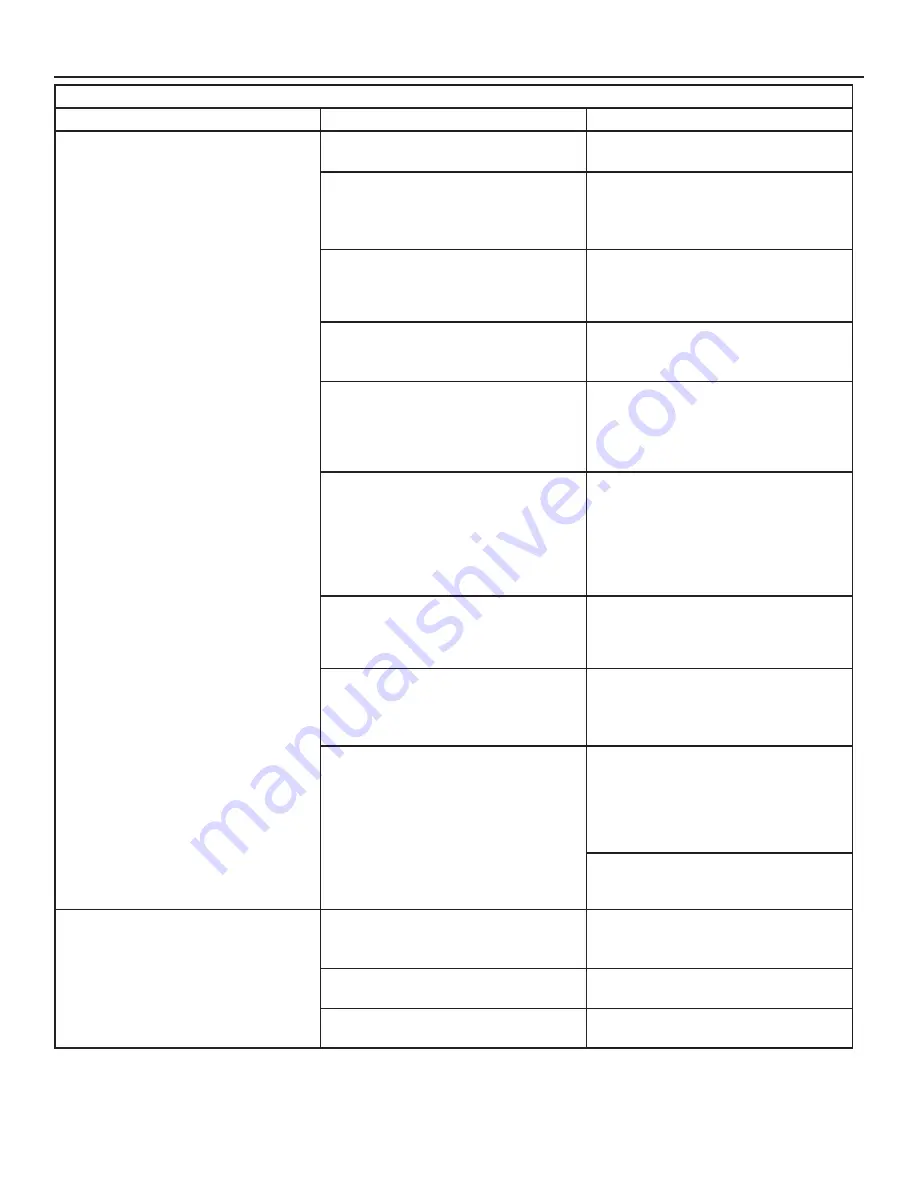

5. Troubleshooting Chart

Troubleshooting Chart

Problem

Possible Causes

Possible Solution

Motor does not run when

control switch is activated.

Cab cut‑off switch.

Turn switch to ON position.

Replacement part — A‑150031

Optional power cut‑off solenoid.

Check solenoid. “4.8 Checking Motor

Start Solenoid and Power Cut‑off

Solenoid” on page <?>.

Replacement part — A‑150263

Dead battery.

Make sure battery is fully charged.

Check for loose or corroded battery

connections. Replace or recharge

battery.

Circuit protection (200 Amp fuse).

Replace fuse. Refer to “4.6 Power Cable

Fuse ‑ 200 Amp” on page <?>.

Replacement part — A‑133610.

Control switch (10 Amp) fuse is blown.

Replace the fuse inside power unit box.

If problem continues, check for shorts

in the electrical system. “4.15 Control

Switch Fuse ‑ 10 Amp” on page <?>

Replacement part — A‑150438.

Battery cable.

Inspect main power cable from

batteries, to circuit breakers, to cut‑off

switch to power unit. To verify a faulty

cable, connect motor directly to a spare

battery using the procedure in the

Maintenance section.

Replacement part — A‑133604

Corroded or loose wire connections.

Check all wire connections on power

unit for corrosion or looseness. Replace

defective terminals with ‘heat shrink’

factory type terminals.

Motor start solenoid.

Check solenoid. “4.8 Checking Motor

Start Solenoid and Power Cut‑off

Solenoid” on page <?>.

Replacement part — ATU‑120.

Power unit motor.

If the motor is determined to be

defective, it should be replaced.

Defective motors are typically caused

by weak batteries (low Voltage), loose

connections, corrosion, or a poor ground.

Replacement part — A‑150018

If the motor does not operate in

freezing conditions, make sure the

motor housing does not contain water.

Sagging platform.

Normal wear.

Add shims to platform. “4.5 Platform

Adjustment” on page <?>.

Replacement part — ATU‑071 SHIM, 14GA

Bushing wear where lift arms connect to

platform.

Replace bushings. Refer to separate

Parts Manual.

Structural damage.

Replace worn parts. Refer to separate

Parts Manual.

Summary of Contents for AC-1600

Page 2: ......