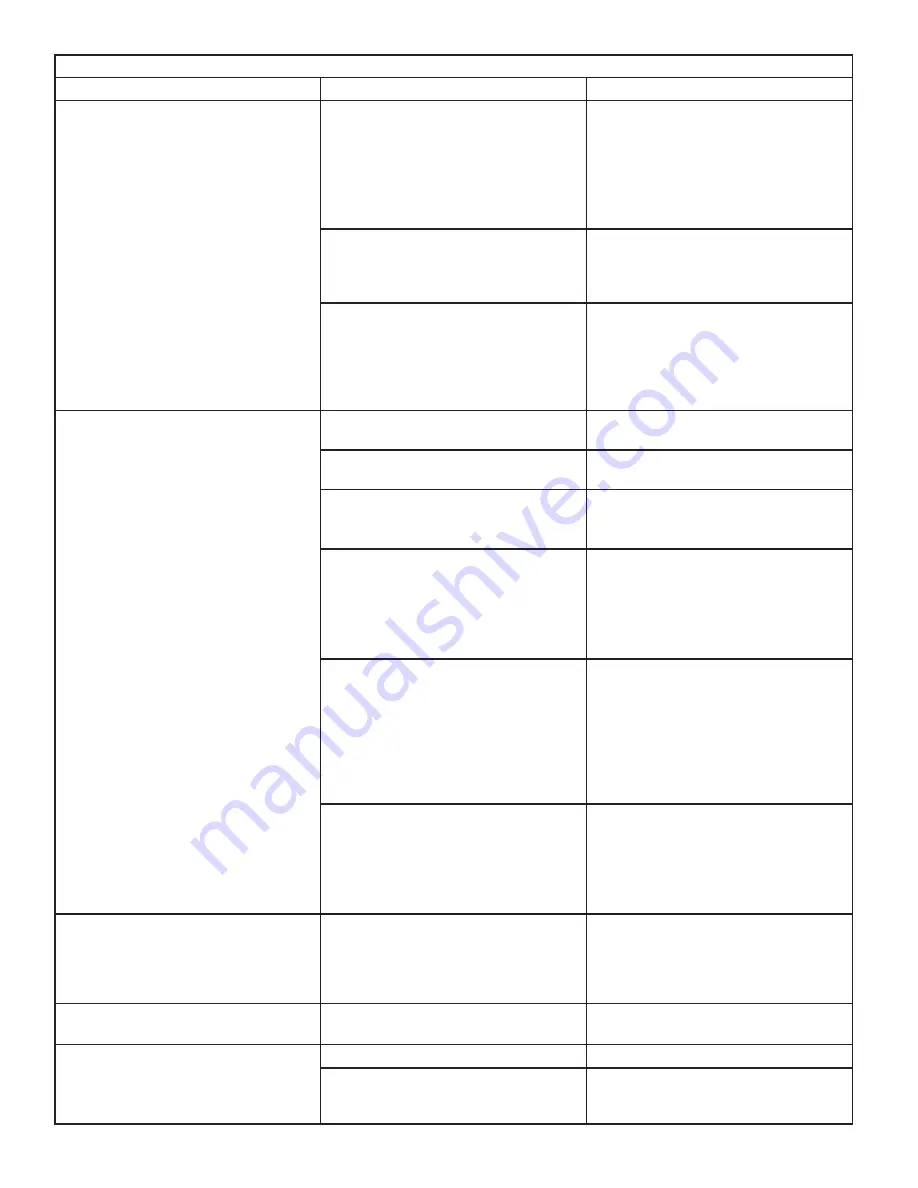

Troubleshooting Chart

Problem

Possible Causes

Possible Solution

Foaming oil.

Air in the hydraulic hose(s) or cylinder.

Fill reservoir with proper fluid. Refer

to “4.1 Monthly Inspection” on page

<?> for oil specifications and “4.3

Check Power Module Fluid Level” on

page <?> for oil level. Raise and lower

platform several times to remove any

trapped air.

Filter screen.

Filter screen in pump reservoir is

damaged or plugged with dirt. Replace

filter screen.

Replacement part — A‑150016.

Broken or loose fluid return tube.

Remove oil reservoir and make sure

return tube is below oil level. If tube

has turned or fallen out, reinstall it into

the pump housing. Use a center punch

to “stake” tube into position.

Replacement part — A‑150015

Motor runs, but liftgate will not open or

platform will not lower to the ground.

Structural damage. Check clearance

between platform and floor extension.

Fix damage. Replace worn parts. Refer

to the separate Parts Manual.

Latch pin.

Slide the latch pin to the open position.

Lowering valve solenoid (power down

models only).

Check the solenoid. “4.9 Checking Valve

Cartridge and Solenoid” on page <?>.

Replacement part — A‑176315.

Lowering valve cartridge (power down

models only).

With platform on ground, check, remove,

and clean valve cartridge using the

procedure in section “4.9 Checking Valve

Cartridge and Solenoid” on page <?>. If

plunger will not move freely, replace.

Replacement part — A‑130216.

Cylinder seals.

Cylinder piston seal are damaged

allowing fluid to leak past piston when

trying to raise platform. Replace the

cylinder, repair is not practical. Refer to

section “4.12 Checking Cylinder Piston

Seals” on page <?>.

Replacement part — A‑130113 Cylinder

3” or A‑130114 Cylinder 4”.

Flow control valve.

Remove flow control valve and hook

hydraulic hose directly to the cylinder.

If the cylinder operates properly, replace

the valve. “4.14 Checking Flow Control

Valve” on page <?>.

Replacement part — A‑130102.

Latch pin is broken or bent.

Operator has lowered platform without

releasing latch pin.

The latch pin is only used to prevent the

liftgate from opening due to a pressure

leak or pressure bleed‑off over an

extended period of time. Always release

latch before opening liftgate.

Platform raises truck when lowered to

the ground (power down models only).

Power down system pressure is set too

high.

See section “4.13 Checking System

Pressure” on page <?>.

Platform will not open.

Platform operating area is not clear.

Clear platform operating area.

Latch pin will not slide freely to release

liftgate.

Activate the “UP” switch and raise the

liftgate to the fully stored position.

The latch pin should slide freely.

Summary of Contents for AC-1600

Page 2: ......