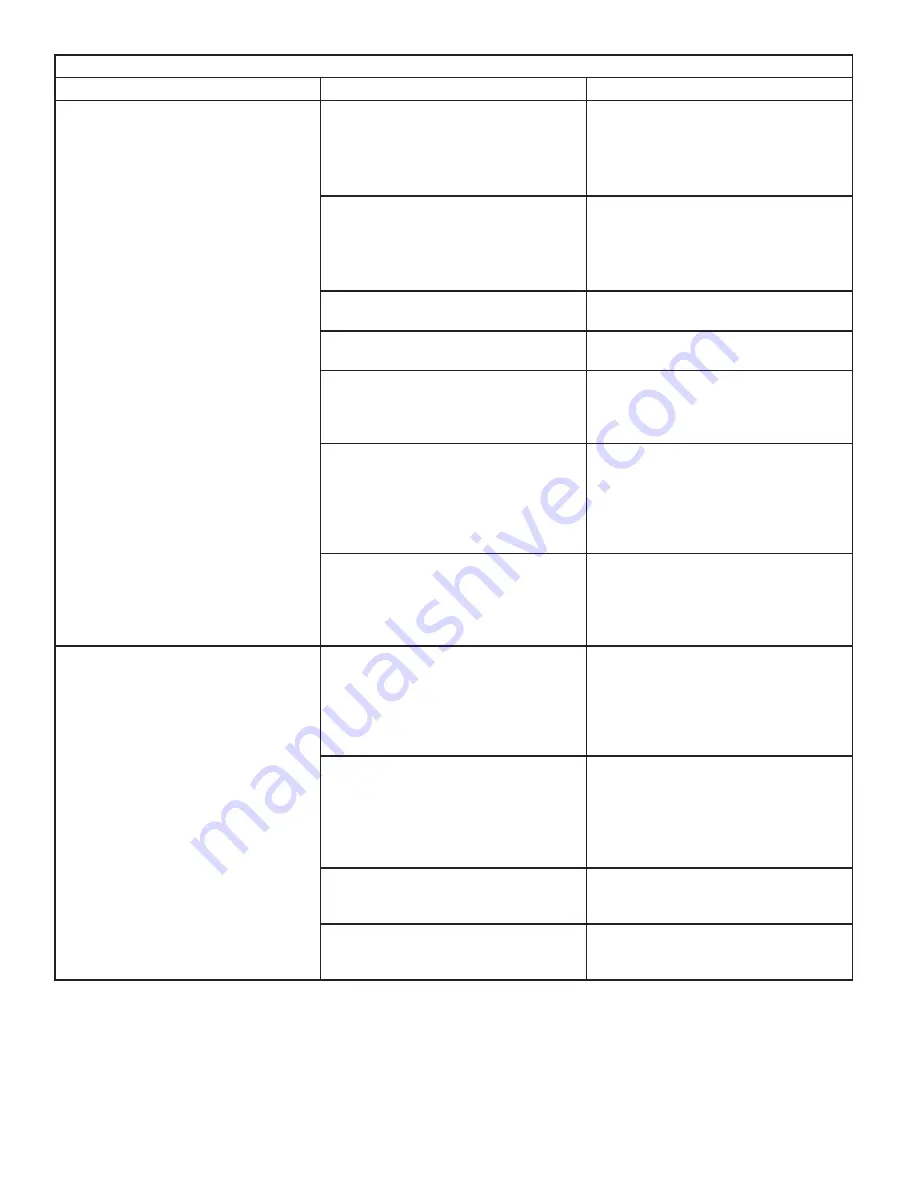

Troubleshooting Chart

Problem

Possible Causes

Possible Solution

Platform lowers extremely slow.

Low oil level on power down models.

Fill reservoir with proper fluid. Refer to

“4.1 Monthly Inspection” on page <?>

for oil specifications and “4.3 Check

Power Module Fluid Level” on page

<?> for oil level.

Improper oil in hydraulic reservoir.

Fill reservoir with proper fluid. Refer to

“4.1 Monthly Inspection” on page <?>

for oil specifications and “4.3 Check

Power Module Fluid Level” on page

<?> for oil level.

Bushing wear where lift arms connect to

platform.

Replace bushings. Refer to the separate

Parts Manual.

Damaged or kinked hydraulic hose.

Repair or replace. Refer to the separate

Parts Manual.

Cylinder rod is scored, pitted, or bent.

Replace the cylinder, repair is not

practical.

Replacement part — A‑130113 Cylinder

3” or A‑130114 Cylinder 4”.

Flow control valve.

Remove flow control valve and hook

hydraulic hose directly to the cylinder.

If the cylinder operates properly, replace

the valve. “4.14 Checking Flow Control

Valve” on page <?>.

Replacement part — A‑130102.

Lowering valve (power down models

only).

Solenoid or cartridge may need

cleaning or replacement. Refer to

section “4.9 Checking Valve Cartridge

and Solenoid” on page <?>.

Replacement part — A‑130216.

Motor runs, but platform will not lift

stated load or drifts down after being

raised.

Low fluid level has caused air in the

lines.

Fill reservoir with proper fluid. Refer

to “4.3 Check Power Module Fluid

Level” on page <?> for oil level and

specifications. Raise and lower the

platform several times to expel any

trapped air.

Lowering valve stuck in the open

position (power down models only).

With platform on ground, check,

remove, and clean valve cartridge using

the procedure in section “4.9 Checking

Valve Cartridge and Solenoid” on page

<?>. If plunger will not move freely,

replace. Replacement part — A‑130216.

Damaged cylinder piston seals.

Refer to section “4.12 Checking

Cylinder Piston Seals” on page <?> for

additional information.

Relief valve is set too low or clogged

with contaminants.

Loosen locknut and turn Allen screw

clockwise to increase pressure.

Remove and clean if necessary.

Summary of Contents for AC-1600

Page 2: ......