1.5 Registration

Refer to the Operation Manual for the serial number

information.

1.6 Warranty

For a detailed copy of the Warranty Statement, refer to

the Operation Manual. To make an online warranty claim,

go to www.anthonyliftgates.com and select CUSTOMER

SERVICE and then select WARRANTY CLAIM.

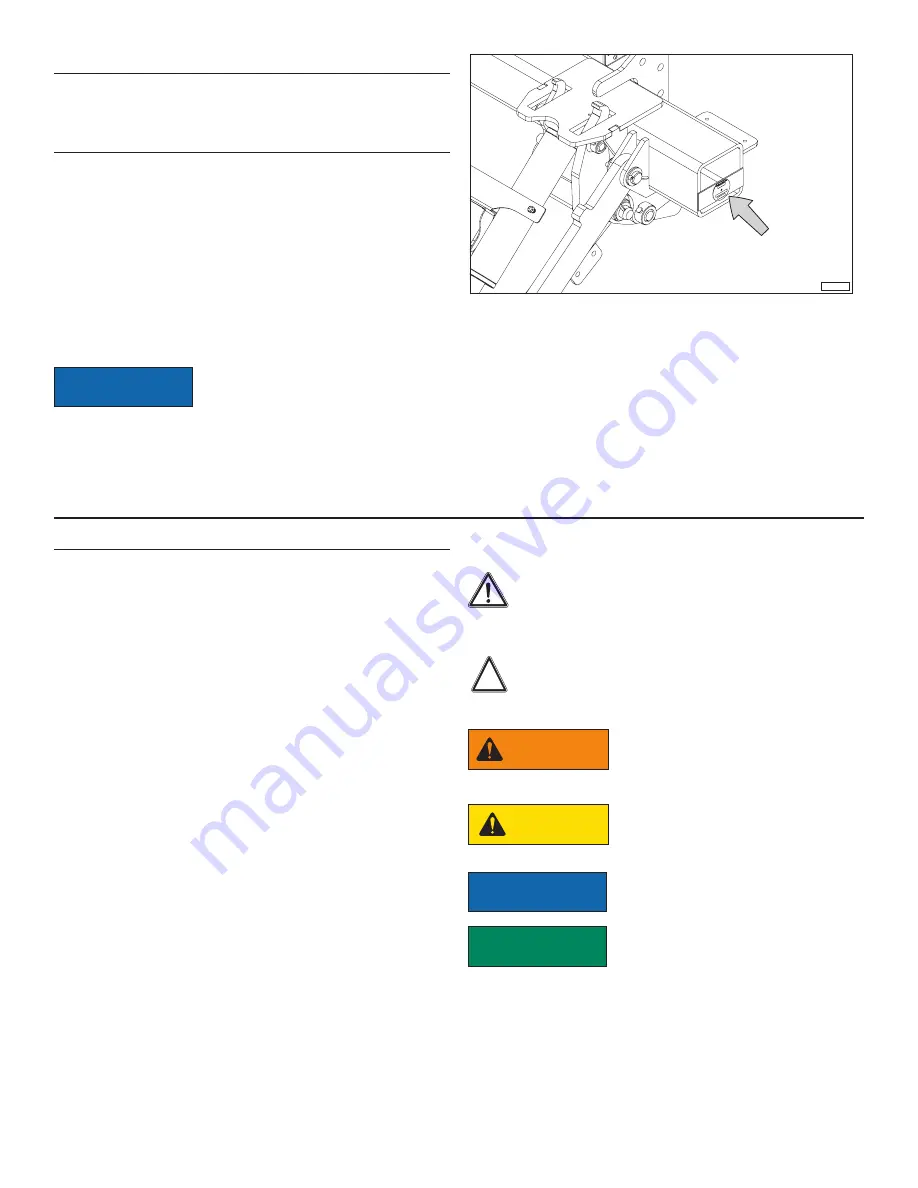

Before calling with questions or other product information

requests, have the serial number, model number, and

lift capacity of the liftgate available. This information is

stamped into the identification plate on the side of the

adapter frame tube.

NOTICE

The liftgate must be maintained

according to these instructions or the

warranty will be void.

ALI-00418

Common location for product information on an Anthony Liftgates liftgate.

1. Unauthorized modifications may cause improper

operation or other unforeseen problems or dangers. If

any deviation is deemed necessary, written permission

must be obtained from Anthony Liftgates.

2. All decals must be attached and legible, or all

warranties are void.

2. Safety

2.1 Safety is Your Responsibility

It is the responsibility of the maintenance personnel to

understand proper operating procedures. Be aware of the

inherent dangers in the use of this product and the tools

used to maintain it. Read and understand all Warnings,

Cautions, Notices, Safety Instructions, and Notes in this

manual, on the liftgate, or on the truck.

Accidents can often be avoided by being alert and

recognizing potentially hazardous situations. The safety

information in this manual serves as a basic guide in an

attempt to prevent injury or death.

Anthony Liftgates cannot anticipate every possible

circumstance that might involve a potential hazard. The

warnings in this manual and on the product itself are,

therefore, not all-inclusive. If tools, procedures, work

methods, or operating techniques are used that are not

specifically mentioned by Anthony Liftgates, you must

satisfy yourself that they are safe for you and for others.

DO NOT proceed with any maintenance procedure if doubt

arises about the correct or safe method of performing any

procedure found in this manual. If you have any doubts or

questions about installation, call your authorized dealer.

Safety Signal Words

Personal injury hazards are identified by the “Safety

Alert Symbol” and followed by a signal word such as

WARNING or CAUTION to indicate the severity of

the hazard.

This safety alert icon surrounds an image showing a

specific type of injury which should be avoided.

These icons are shown on page 3.

WARNING

Indicates a potentially hazardous

situation which, if not avoided,

COULD result in death or serious

injury.

CAUTION

Indicates a potentially hazardous

situation which, if not avoided,

MAY result in minor or moderate

injury.

NOTICE

Indicates that equipment or property

damage can result if instructions are

not followed.

SAFETY

INSTRUCTIONS

Indicates specific safety-related

instructions or procedures.

Note:

Contains additional information important to a

procedure.

Summary of Contents for AC-1600

Page 2: ......