Anthony Liftgates, Inc.

10

MTU-GLR Maintenance

www.anthonyliftgates.com

800-482-0003

4. Maintenance

4.1 Monthly Inspection

All Anthony Tuckunder Liftgates are “Service-Free” which

means they have lubrication-free bushings at the major

pivot points.

Mechanical Components

1. Make sure the liftgate operates freely and smoothly

throughout its entire range of movement.

2. Check for damage to the liftgate, such as bent or

distorted parts. Check for excessively worn parts.

3. Check for cracked welds which may have resulted

from overload or abuse.

4. Check all pins and pivot points. Secure all pins with

proper retainers. Replace worn bushings and pins.

5. Oil the roller of the wheel arm and make sure it spins

freely.

6. Make sure the platform is angled upward from truck

bed 1/2 to 3/4 inch when raised to bed height. See

Platform Adjustment for shimming procedure, “3.3

Mechanical Platform Adjustment” on page 8.

Power Unit

7. Check for oil leaks in the following areas:

a. Hydraulic lift cylinder.

b. Hydraulic hoses. Replace any hose that shows

signs of leakage or excessive abrasion of the

covering.

c. Check all hydraulic fittings for damage or leakage.

Tighten fittings to stop leaks or replace if damaged.

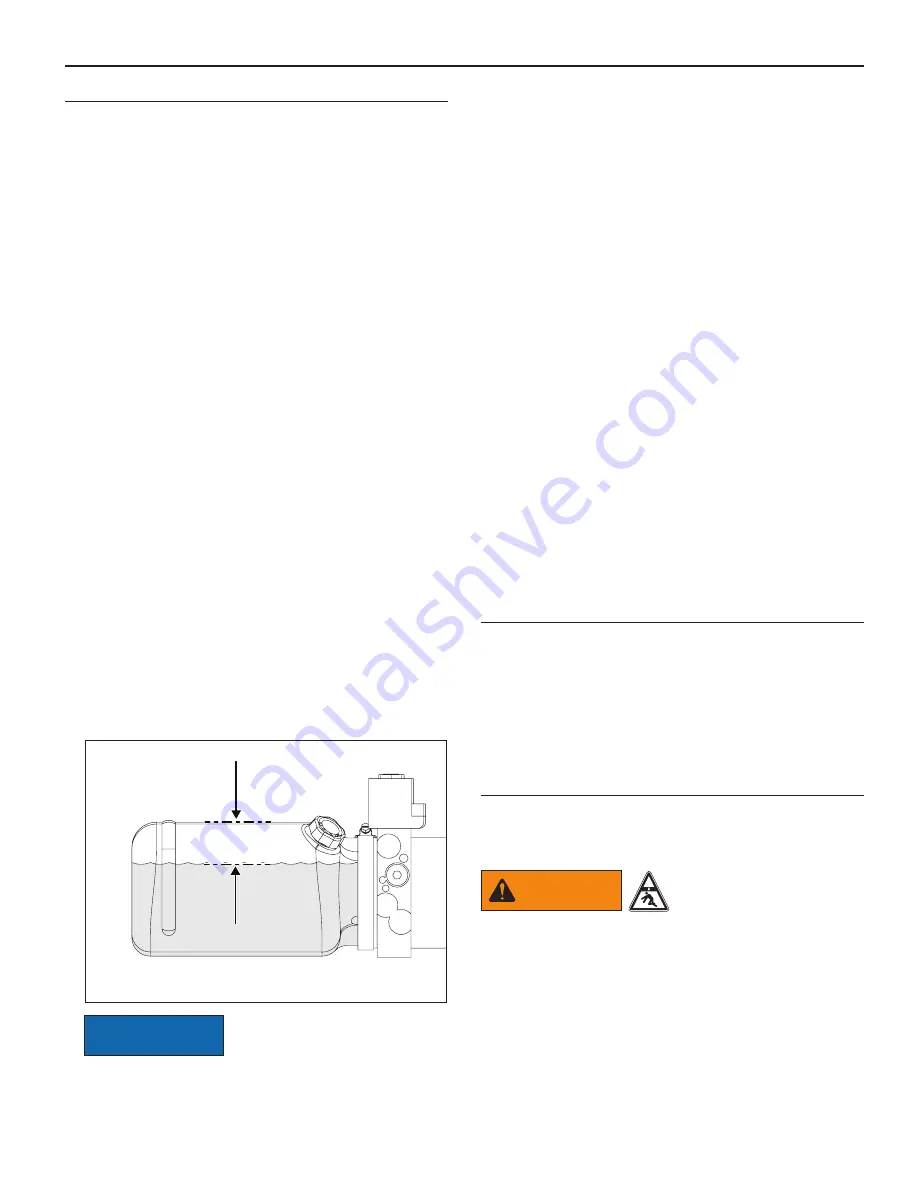

8. Check reservoir oil level. The fluid level should be 2

inches from the top of the reservoir when the liftgate

platform is in the fully raised position. Fill as required

with Hyken Glacial Blu.

2”

ALI-00613a

NOTICE

To prevent damage to the pump,

use only the recommended

Hyken Glacial Blu anti-wear, low-

viscosity, hydraulic fluid in the power unit reservoir.

In an emergency, use any anti-wear hydraulic fluid, but

flush the system and replace it with our recommended

fluid soon as reasonably possible. Do not mix hydraulic

oil and automatic transmission fluid due to possible

compatibility problems.

Use the appropriate viscosity of fluid based on the

surrounding climate conditions. Viscosity is important

because the pump will not cause a temperature increase

to the oil in the reservoir, like a typical closed-loop

hydraulic system.

DO NOT use brake fluid in place of our recommended

fluids.

Electrical Components

9. Make sure all electrical wires, switches, and

connections are in good working condition and

operate properly.

10. Proper wire connection is crucial to the life and

dependability of the liftgate’s electrical components.

A poor connection can result in low Voltage, causing

the liftgate to work incorrectly.

11. Check the fluid level of the vehicle battery. Fill as

required.

Safety Signs and Informational Decals

12. Examine all warning, capacity, and operational

decals. If they are not readable, replace them.

Decals may be obtained free of charge your

authorized dealer.

4.2 Semi-Annual Inspection

In addition to the items requiring monthly inspection, also

inspect the condition of the hydraulic fluid.

If the oil in the hydraulic tank is dirty, drain the oil and

flush the entire system. Refill the system with the

recommended oil outlined in Step 8 of the “Monthly

Inspection” section.

4.3 Adjusting Wheel Arm

The wheel arm helps unfold the platform as it is lowered

from the stored position. The wheel arm can be adjusted,

so the platform unfolds with either greater or lesser effort.

WARNING

Never stand behind the

liftgate when it is opened.

Always stand to the side

and away from the edge of the platform.

When adjusting the position of the wheel arm, consider

that the vehicle may be parked on an upward sloped

surface. Adjust the wheel arm to prevent the platform

from completely unfolding in this type of situation.

1. If adjustment is needed, remove the two bolts and

nuts on the wheel arm.

Summary of Contents for MTU-GLR Series

Page 2: ......

Page 23: ...NOTES...