Anthony Liftgates, Inc.

4

MTU-GLR Maintenance

www.anthonyliftgates.com

800-482-0003

1. General Information

1.1 Introduction

Congratulations on selecting an Anthony Liftgates

TuckUnder™ liftgate.

All Anthony tuckunder model liftgates are factory

assembled, energized, and tested to ensure the highest

quality performance standards. MTU-GLR liftgates

ship completely assembled for fast, clean, and easy

installation.

To ensure your liftgate will perform to your expectations,

we have provided this Installation Manual, which is

designed to provide you with the necessary installation

instructions and safety precautions for the installation of

the MTU-GLR TuckUnder™ liftgates.

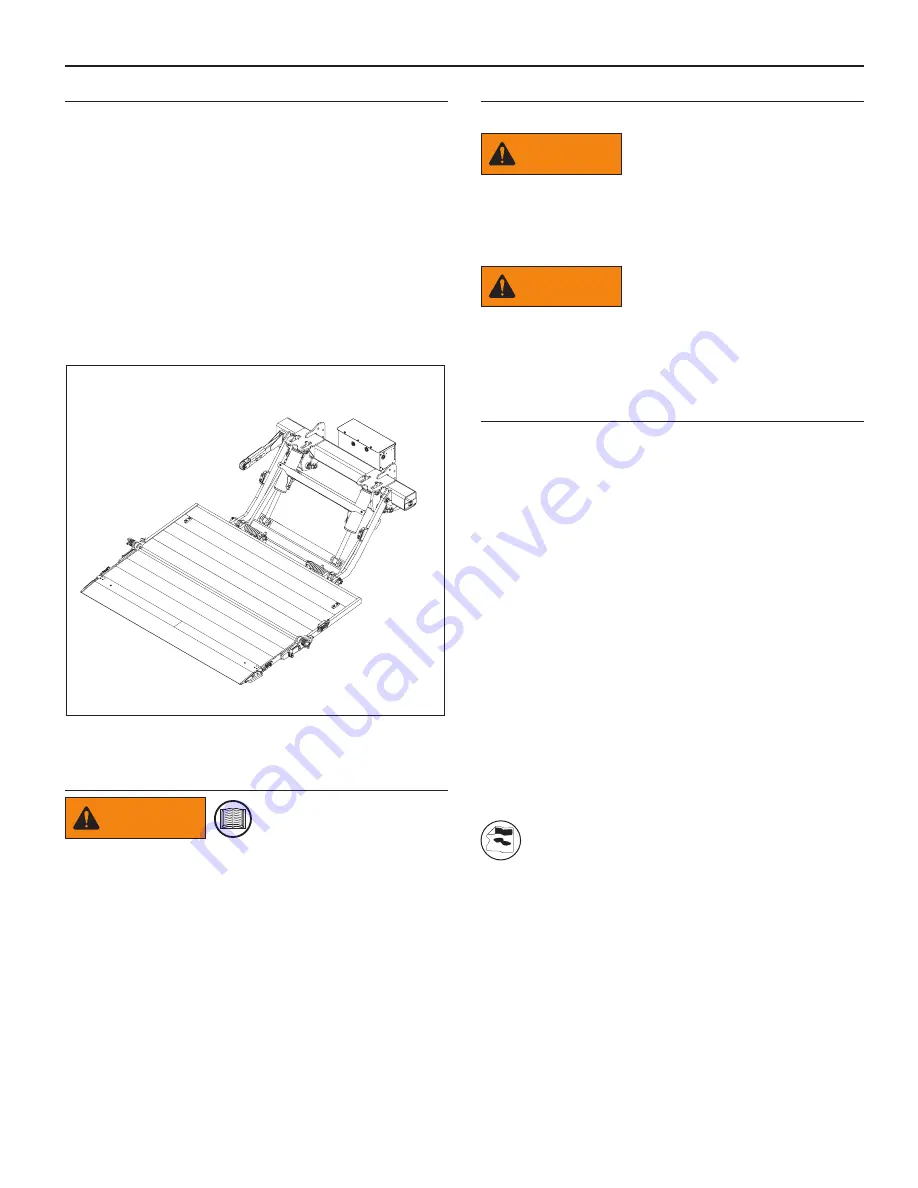

Typical Anthony Liftgates Tuckunder Model.

1.2 General Safety

WARNING

Read, Understand, and

Follow the Manual

The success or failure of

this liftgate to properly and efficiently operate depends

on an ongoing preventative maintenance program.

Failure to read, understand, and follow the maintenance

instructions and safety recommendations in this

manual can result in serious injury or death.

Also, read and understand the operating instructions

in the separate Operation Manual before performing

any maintenance.

1.3 State and Federal Regulations

1.3.1 Lighting

WARNING

If any lighting is installed or

changed, it must not alter or

prevent vehicle compliance with

any existing State or Federal standards such as

FMVSS 108 – Lamps, Reflective Devices, and

Associated Equipment.

1.3.2 Rear Impact Guards

WARNING

When stored in the transport

position, this liftgate must

provide protection against rear

impact and comply with State and Federal standards

in your area. Anthony Liftgates offers a bolt-on

bumper, which meets the requirements of this

standard.

1.4 If Maintenance Help is Required

1.4.1 Maintenance (Dealer)

For additional information on installation, refer to

the MTU-GLR TuckUnder™ liftgate website www.

anthonyliftgates.com. To find the most current version

of the reference material, choose LIFTGATES,

TUCKUNDER™, MTU-GLR, and then DOWNLOADS.

If you have any doubts or questions about installation,

call us. Before doing so, have the serial number, model

number, and lift capacity of your liftgate available.

Anthony Liftgates, Inc.

1037 West Howard Street

Pontiac, Illinois 61764

(815) 842-3383 or 800-482-0003

1.4.2 Customer Service and Parts (End User)

For service or ordering replacement parts, contact an

authorized dealer by going to www.anthonyliftgates.com

and selecting the FIND A DEALER tab. Enter your zip

code to find the nearest authorized service location.

N ING

AR

Being unaware of safety recommendations can

lead to personal injury. The user must make

sure all decals are attached to the liftgate and

truck and are legible.

Summary of Contents for MTU-GLR Series

Page 2: ......

Page 23: ...NOTES...