8 Upkeep and Cleaning

32

C58IB004EN-D

8 Upkeep and Cleaning

8.1 Checking the Dome

The dome should be regularly checked, depending

on the operating hours, the usual operating tem-

peratures and the applied atmospheres.

8.2 Replacing the O-rings

In general, commercially available O-rings made of

Viton are used.

While detaching an O-ring, make sure that the seal-

ing surfaces remain undamaged.

Before fitting a new O-ring, clean the sealing surfac-

es with a suitable solvent.

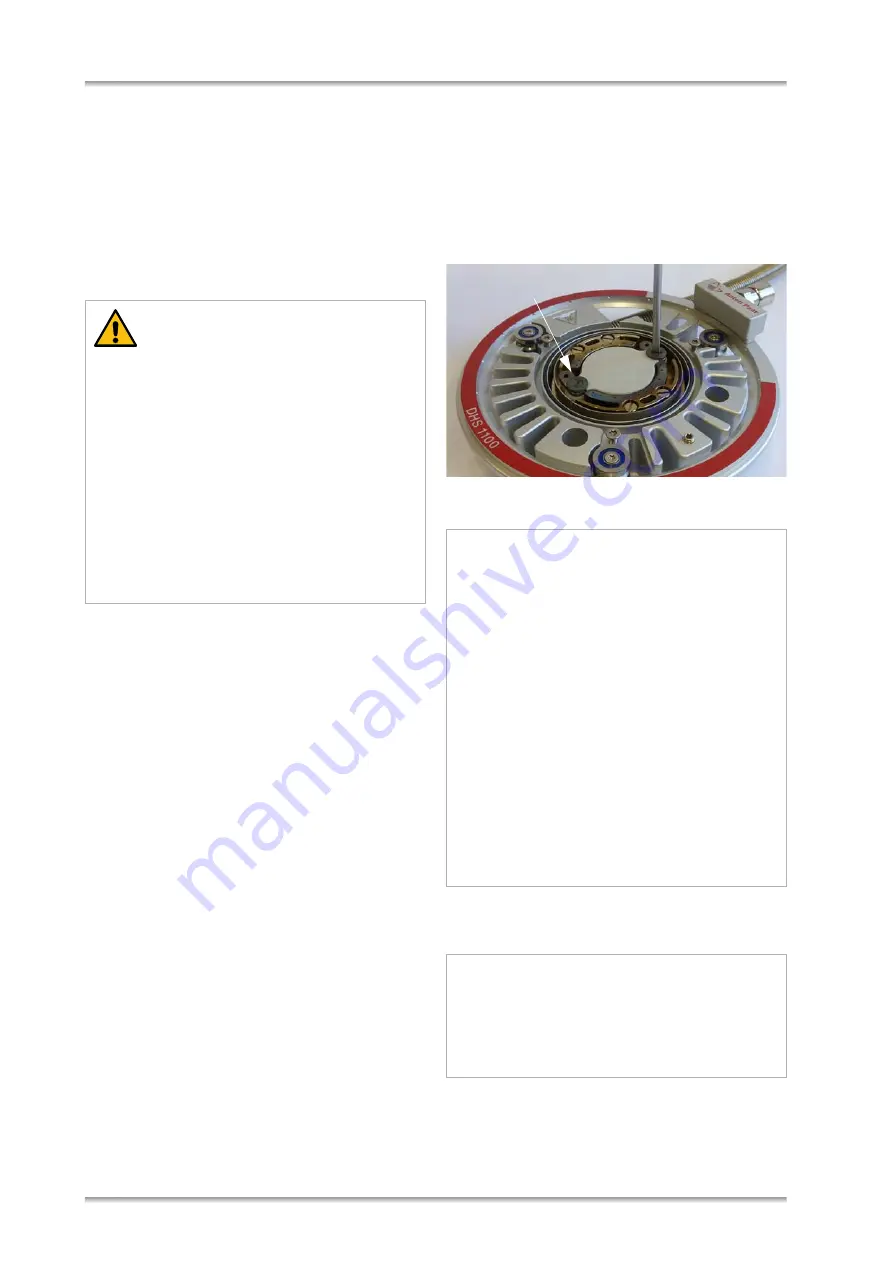

8.3 Changing the Hot Plate

1. Open the sample plate fixing screws.

2. Remove the old hot plate.

3. Mount the new hot plate and remount the

screws.

CAUTION

• Always lift the dome by the fixing ring.

• Never touch the dome during operation,

especially when it is evacuated or at elevated

temperatures.

• Check the dome for cracks and coatings on

the inner surface.

• If the inner surface of the dome has become

coated with evaporated sample components,

clean it with a dry cloth.

If cracks are observed, replace the dome (refer

to the reference guide C58IB002EN).

NOTICE

The cavities between the heating wires are filled

with a ceramic paste. This paste provides a good

thermal contact between the heater and the hot

plate. Moreover, it acts as electrical insulation

between the heating wires. Depending on the

previous thermal treatment different cases can

occur.

• The surface of the ceramic is rough.

Please use an abrasive paper and gently

smoothen the surface to provide a good thermal

contact to the hot plate.

• Parts of the ceramic powder are brittle and

fall off the heater. The resulting cavities would

give poor thermal accuracy.

Please send the DHS 1100 to Anton Paar to

repair the heater.

NOTICE

It is recommended to validate the temperature of

the new hot plate by either measuring the transi-

tion points of known standards or by using the

thermal expansion method of known sub-

stances.