HEBT-3V BUN TOASTER

11

P/N 1011314 Rev. D 05/16

McDonald’s

MAINTENANCE (continued)

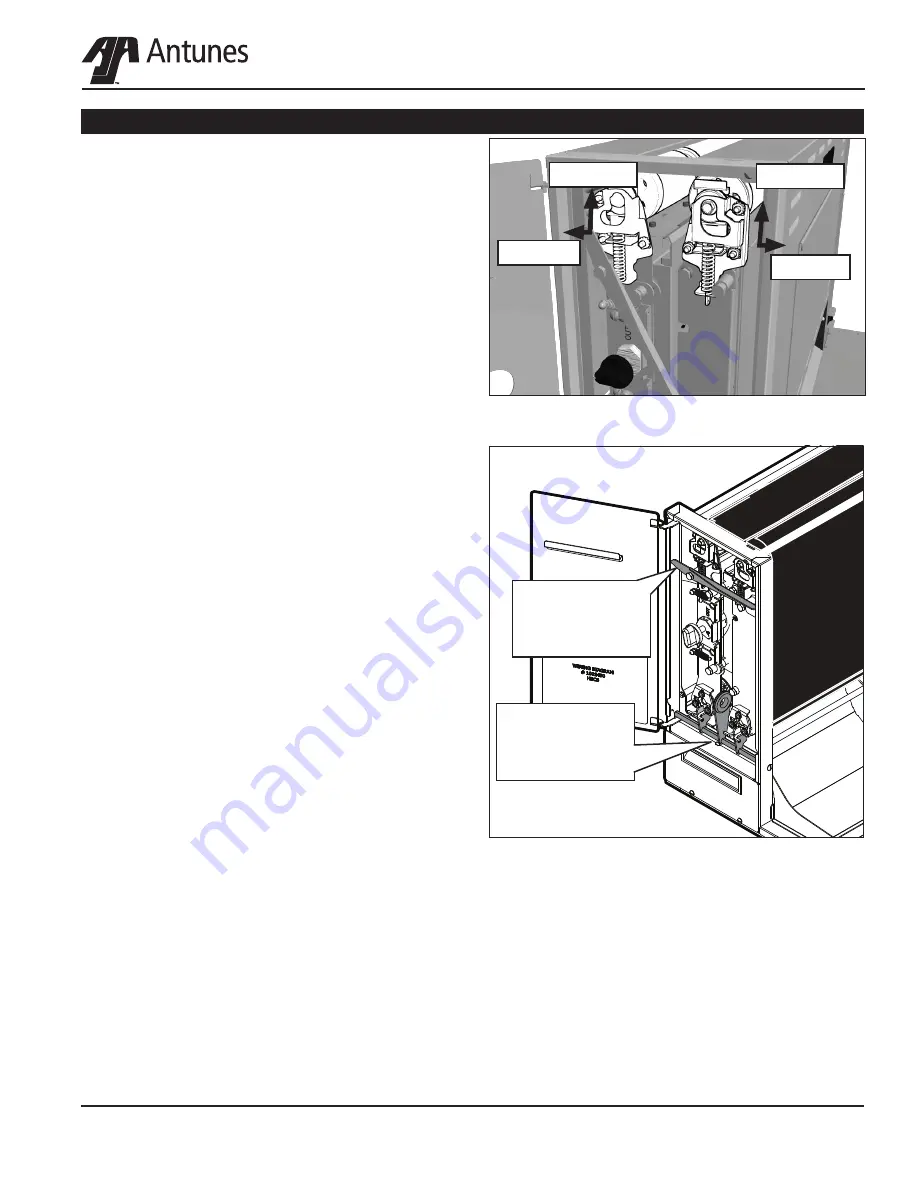

Figure 10. Conveyor Rollers

Figure 11. Conveyor Locks

INSTALLING BELTS

1. Follow the steps for

Removing Belts

.

2. Wipe both sides of the new Belts with a clean,

sanitized towel sprayed with an approved sanitizer

and allow to air dry.

3. Wipe all four rollers and the backing plate with

a clean towel sprayed with sanitizer. Make sure

to remove all debris from the rollers and backing

plate so they are as clean as possible.

4. Slide the new front belt gently over the front top

roller and front bottom roller.

NOTE: Make sure the belt lines up properly on the

rollers. The snaps on the belts should face the

inside of the top front roller.

5. Slide the first crown belt over the rear top roller

and rear bottom roller. Repeat this step for the

club/ heel belt and the second crown belt.

NOTE: Make sure the belt lines up properly on the

rollers. The snaps on the belts should face the

inside of the top rear roller.

6. Return the Front and Rear Belt Rollers to full ten-

sion by lifting them up so each roller locks into

place (Figure 10).

7. Slowly lift up the Lower Belt Frame Lock so the

Front and Rear Belt Rollers lock into place (Figure

11). If necessary, lift up the cam shaft of the Rear

Belt Roller while lifting the Lower Belt Frame Lock

into place.

8. Re-engage the Upper Belt Frame Lock by lift-

ing up and then locking it in place on the Front

Conveyor Assembly (Figure 11).

9. Close and latch the Side Panel.

NOTE: Inform the Store Manager after any Belt

Replacement so new Belts can be ordered. To

obtain new Belts, contact the factory at 1-877-392-

7854 (North America only) or 630-784-1000.

10. Set the Compression Knob to 4.

11. Re-install the Front and Rear Conveyor Covers

and then the Bun Feeder Assembly.

12. Plug in the toaster and test the unit before

returning to service.

Upper

Conveyor

Lock

Lower

Conveyor

Lock

Tense

Loose

Loose

Tense