VERTICAL CONTACT TOASTER

12

P/N 1010838 Rev. P 10/16

Burger King

Monthly

REPLACING THE BLACK AND SILVER RELEASE SHEET

NOTE: Depending on usage and level of cleaning,

the Release Sheet may last up to 45-60 days.

1. Remove and discard the Release Sheet.

2. Lay a new Release Sheet on a clean, dry surface

and fold it in half lengthwise. Then gently crease it

at the fold using only your fingers (see below).

3. Install the Release Sheet into toaster.

Fold over so

ends meet.

Press Lightly

with finger to

form crease.

11. Install the Release Sheet by placing it over both

sides of the Platen with the crease centered on

the Platen.

NOTE: Extend the life of the Release Sheet by

rotating from the black side to the silver side on a

daily or weekly basis.

12. Install the Bun Chute so the hooks are over the

lower rear Support Rod. Install the Heat Shield

with the Release Sheet retainer clips securely

over the Release Sheet and Platen.

13. Reinstall the Bun Feeder and plug in the unit.

NOTE: Make sure the Heat Shield is activating the

Conveyor Safety Interlock Switch. The Conveyors

will not rotate unless the Heat Shield is in place

and the Conveyor Safety Interlock Switch is acti-

vated.

NOTE: Check the Release Sheet to make sure it

is not caught in the Conveyor. Additional release

Sheets can be obtained through your Authorized

Service Agency under P/N 7000249 (3-Pack) or

7000250 (10-Pack).

MAINTENANCE (continued)

CAUTION

Failure to use Release Sheets may result in dam-

age to the unit and loss of warranty coverage.

Figure 4. Removing Conveyor Belt

Rotation

Upper Support Rod

Large Link

P/N 0800121

Small Link

P/N 0800204

MEASURING CONVEYOR BELT

Facing the toaster, locate

the approximate center

point of the Conveyor

Chain. Pull the chain

away from the edge of

the toaster. Stand a U.S.

Dime, 11/16” (1.8 cm) coin

on end between the frame

and the chain. If the gap

is significantly wider than

the coin, REMOVE links as described below. Then,

measure the gap again to make sure it is not too tight.

Check the opposite side of the toaster using the same

measurements.

3. To shorten a stretched Conveyor Belt Chain,

remove one 1/2” link from the belt.

4. Reassemble the Conveyor Belt Chain onto the

sprockets as described below.

NOTE: If the belt is too short to be reassembled,

remove a second 1/2” small link and install a 3/4”

large link. This will shorten the belt by 1/4” overall.

WARNING

Turn the unit off, disconnect the power source,

and allow the unit to cool down before performing

any service or maintenance on the unit.

REMOVING CONVEYOR BELTS

After a period of time, the Conveyor Chain links will

wear and the chain will stretch, eventually skipping on

the sprockets. This is easily fixed by removing one or

more conveyor links from each side of the belt.

1. Perform steps 1-4 under

Replacing Belt Wraps

on the previous page.

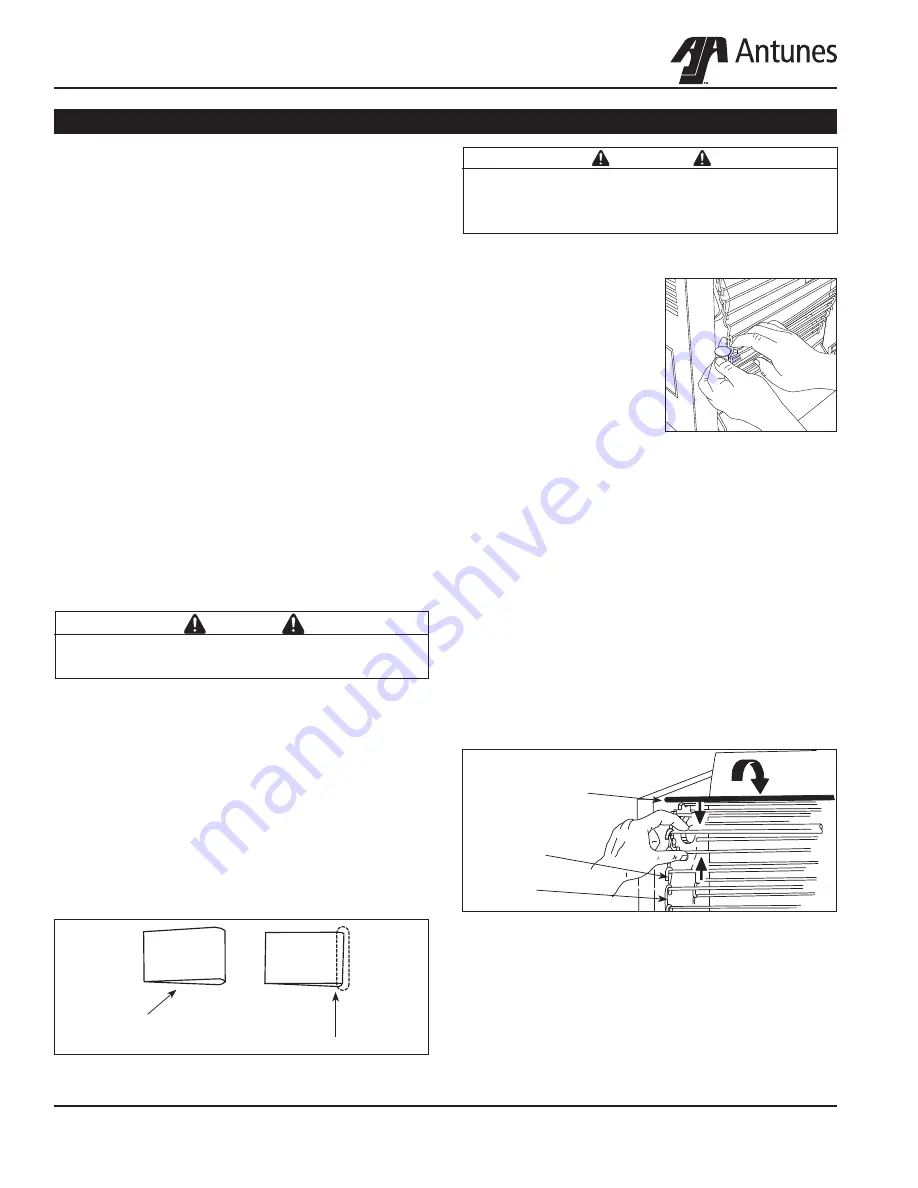

2. Disconnect the Conveyor Belt Chain by squeez-

ing any two links together and unhooking both

ends of one link (Figure 4).