VERTICAL CONTACT TOASTER

15

P/N 1011287 Rev. E 02/18

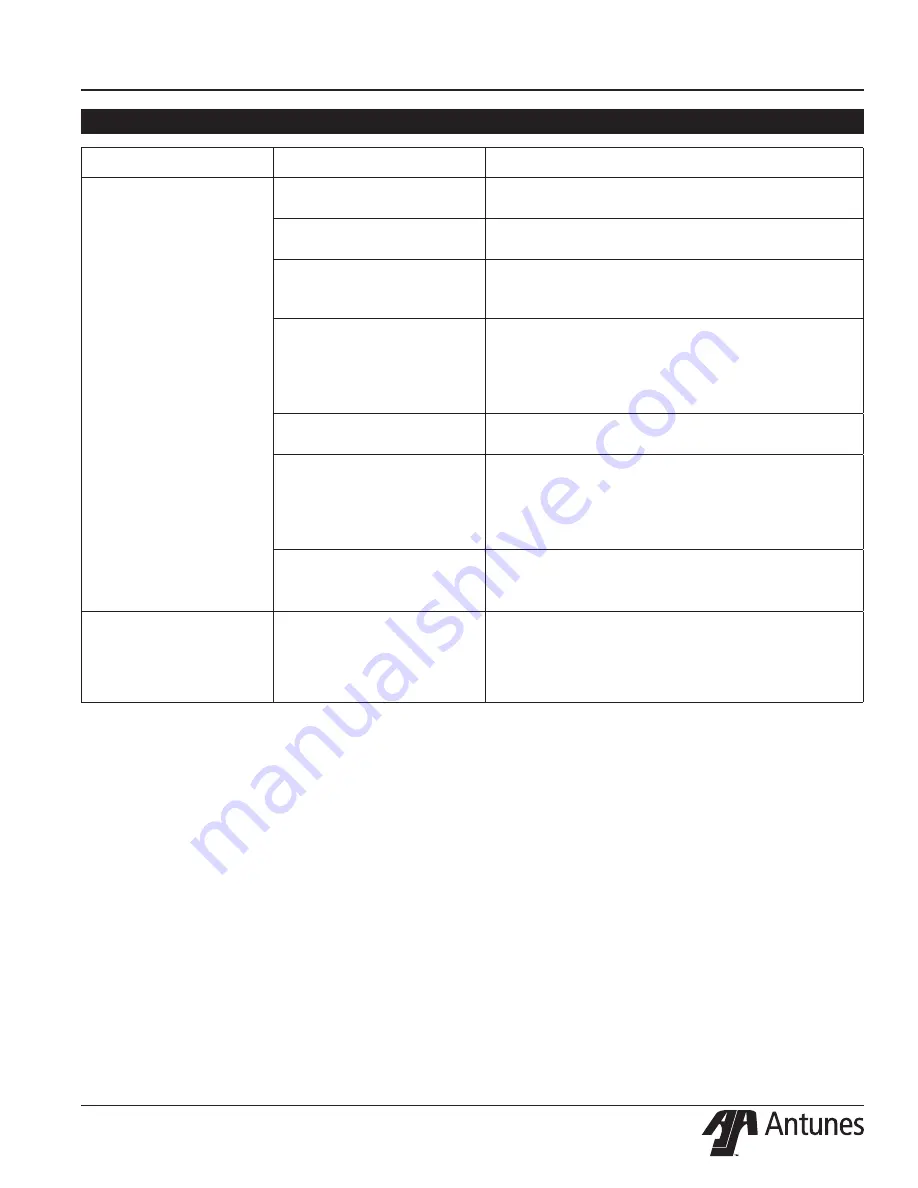

TROUBLESHOOTING (continued)

Problem

Possible Cause

Corrective Action

Conveyor belts are

“jumping” or “snapping”.

Toaster is installed incor-

rectly.

Perform installation and operating procedures.

Bun adjustment controls set

incorrectly.

Measure bun thickness and set bun adjustment con-

trols correctly.

Conveyor drive motor inop-

erative or incorrect conveyor

motor installed on toaster.

Contact your Maintenance Person or Antunes

Technical Service for service.

Conveyor drive chain loose,

worn or broken. Loose

motor drive sprocket.

Check drive chain for kinks, broken or bent links

or other damage. Check motor sprocket and drive

sprockets (on drive shaft); tighten setscrew on flat of

shaft if required. Check for damaged/worn sprockets

and replace as required.

Conveyor belts installed

incorrectly.

Install conveyor belt to match diagram in Fig. 8 (page

10). Be sure that ends of the hooks are facing down.

Conveyor belt too loose

or missing links (41 links

required when new). When

new, conveyor has 37 large

links and 4 small links.

Remove conveyor belt. Lay belt flat and count links.

Replace entire belt if links are damaged. If conveyor

belt has too much play, it will jam. Adjust belt length

as described under Servicing the Conveyor Belt.

Roller Tensioner assy(s). or

tensioner bent or missing.

Replace Roller Tensioner assy(s) or tensioners if

damaged or loose. Replace slide rails if worn or

missing.

Crown and/or heel must

be forced into toaster.

Heat shield improperly

installed.

Crown and/or heel improp-

erly inserted into toaster.

Remove and reposition heat shield.

Buns must be inserted with cut faces facing each

other; heel in front slot and crown in rear slot.