5

P/N 1010454 Rev. F 12/16

INSTALLATION

1. Remove the unit and all packing

materials from the shipping carton.

2. The unit should come with the items

listed below:

• Owner’s Manual

• Spatula Assembly (MS-150 only)

• Drawer Assembly (MS-155 only)

NOTE: If any parts are missing or dam-

aged, contact A.J. Antunes IMMEDIATELY

at 1-800-253-2991 or 1-630-784-1000.

3. Remove all packing materials and pro-

tective coverings from the unit.

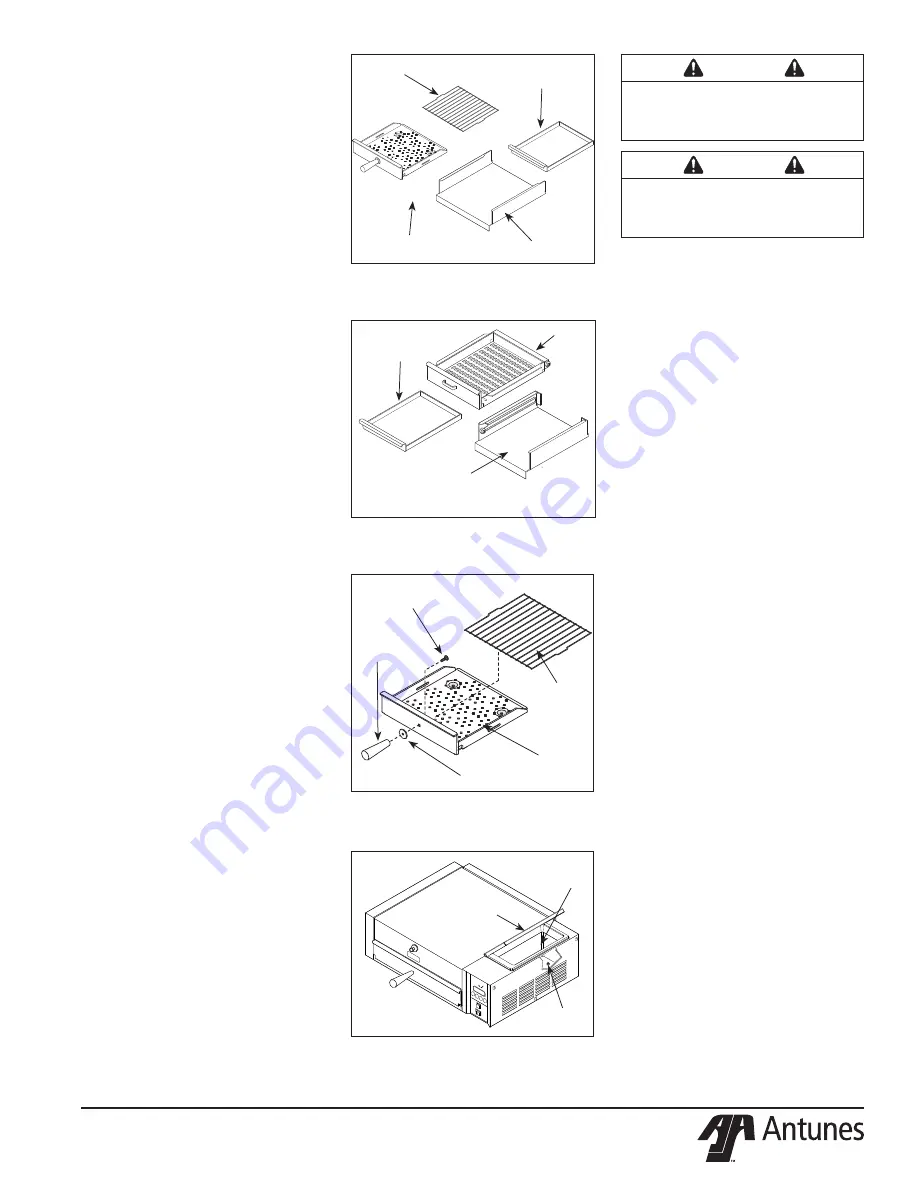

4. MS-150:

Remove and wash the Wire

Trivet, Spatula, Spatula Liner, and

Drip Pan (Figure 1) in soap and water.

Rinse with clean hot water and allow

to air dry.

MS-155:

Remove and wash the

Drawer, Drawer Liner with Rollers, and

Drip Pan (Figure 2) in soap and water.

Rinse with clean hot water and allow

to air dry.

5. Wipe all surfaces of the unit with a

hot, damp cloth.

NOTE: Do NOT use a dripping wet cloth.

Wring out before use.

6. MS-150 Models:

Assemble the

Handle, Handle Guard and Mounting

Bolt to the Spatula (Figure 3).

7. Install the Wire Trivet into the side

slots on the Spatula.

8. Re-install all removed parts.

When placing the unit into service, pay atten-

tion to the following guidelines:

• Make sure power is off and the unit is

at room temperature.

• Do NOT block or cover any openings

on the unit.

• Do NOT immerse cord or plug in

water.

• Keep cord away from heated surfaces.

• Do NOT allow cord to hang over edge

of table or counter.

Figure 2. Washing Parts

(MS-155 Only)

Spatula

Wire Trivet

Drip Pan

Drawer

Drawer Liner

with Rollers

Drip Pan

Spatula Liner

Figure 1. Washing Parts

(MS-150 Only)

Figure 3. Assembling Handle

(MS-150 Only)

Bolt

Handle

Spatula

Handle Guard

Wire Trivet

ELECTRICAL

Plug the power cord into the appropriate

power outlet. Refer to the specification plate

for the proper voltage.

1. Place the unit on a sturdy, level table

or other work surface.

2. Turn off the power.

3. Ensure that the line voltage corre-

sponds to the stated voltage on the

units specification label and power

cord warning tag. If you are unsure of

your Line Voltage, contact an electri-

cian.

4. Connect the unit to the power supply.

PLUMBING

NOTE: Miracle Steamer models are

designed to use cold tap water. Distilled

water may be used to reduce calcium/

mineral deposit buildup and reduce main-

tenance costs.

The MS-150/155 models have a self-contained

water tank. To fill the self-contained water

tank:

1. Open the Tank Cover on top of the

unit (Figure 4).

NOTE: Make sure filter inside tank is

installed properly.

2. Pour in cold tap water. The tank will

hold approximately 3 quarts (2.81

liters).

3. Close the Tank Cover.

NOTE: Do NOT overfill the unit’s water

tank. Only fill the tank to 90% full.

READ

Y

Figure 4. Filling Water Tank

Filter

Tank Cover

Tank

WARNING

Be sure to follow all the precautions, proce-

dures, and safety steps listed in the Important

Safety Information section of this manual.

WARNING

All electrical connections must be in accor-

dance with local electrical codes and any other

applicable codes.