1007 & 3007 ROLL GROOVER

20

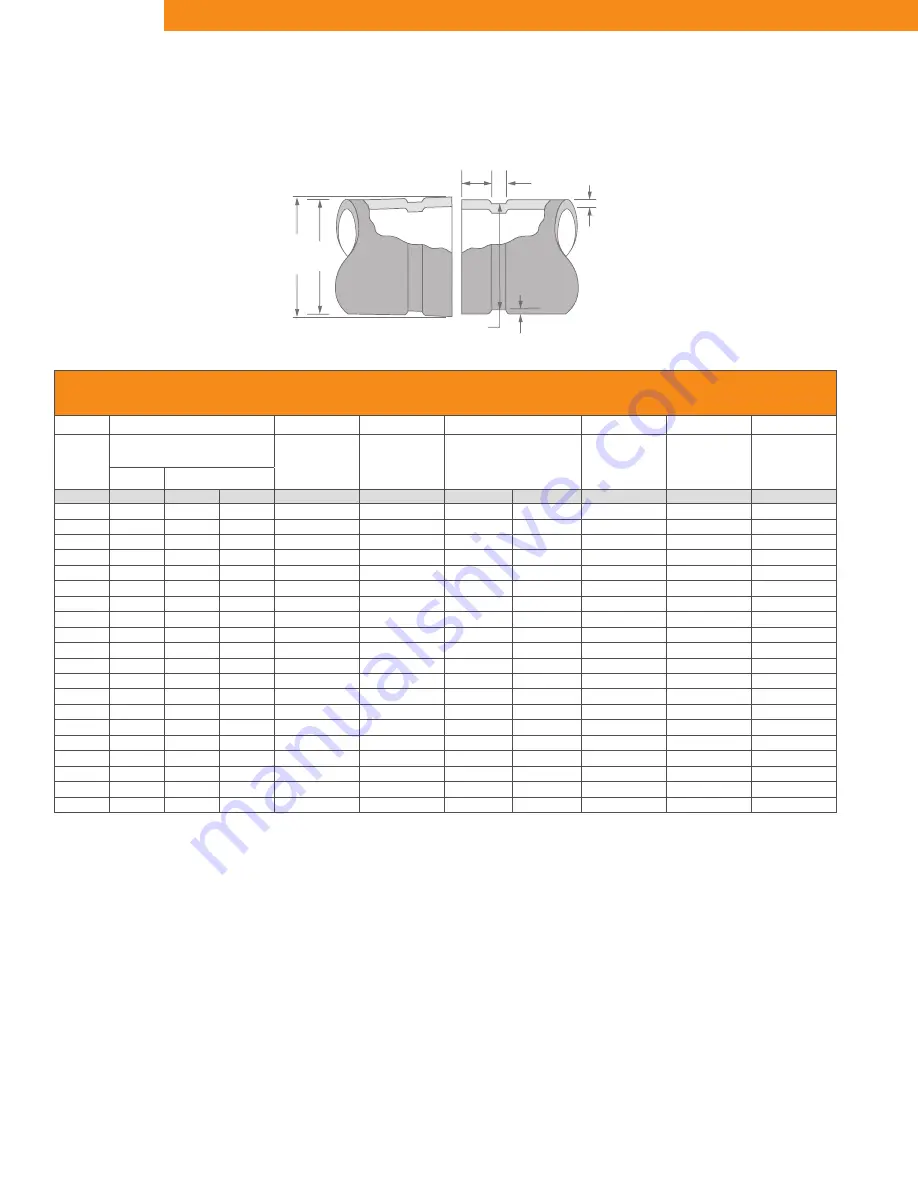

COLUMN 1 - Nominal IPS Pipe size

COLUMN 2 - IPS outside diameter

COLUMN 3 - Gasket seat must be free from

scores, seams, chips, rust or scale

which may interfere with proper

sealing of the gasket. Gasket

seat width (Dimension A) is to be

measured from the pipe end to the

vertical flank in the groove wall.

COLUMN 4 - Groove width (Dimension B) is to be

measured between vertical flank of

the groove size walls.

COLUMN 5 - The groove must be of uniform

depth around the entire pipe cir-

cumference. (See column 6).

COLUMN 6 - Groove depth: for reference only.

Groove must conform to the groove

diameter “C” listed in column 5.

COLUMN 7 - Minimum allowable wall thickness

which may be roll grooved.

COLUMN 8 - Maximum allowable pipe end flare

diameter. Measured at the most

extreme pipe end diameter of the

gasket seat area.

GRUVLOK STANDARD ROLL GROOVE SPECIFICATIONS FOR STEEL & OTHER IPS SIZE PIPE

-1-

-2-

-3-

-4-

-5-

-6-

-7-

-8-

Nominal

IPS

Pipe Size

Pipe OD

Gasket Seat

Groove Width

Groove Diameter

Groove Depth

Min. Allow.

Wall Thickness

“T”

Max.

Flare

Diameter

“A”

“B”

“C”

“D”

Actual

Tolerance

±0.030/ ±0.76 ±0.030/ ±0.76

Actual

Tol. +0.000

(Ref. Only)

In./DN(mm)

In./mm

+In./mm

-In./mm

In./mm

In./mm

In./mm

-In./mm

In./mm

In./mm

In./mm

2

2.375

+0.024

-0.024

0.625

0.344

2.250

-0.015

0.063

0.065

2.480

50

60.3

+0.61

-0.61

15.88

8.74

57.15

-0.38

1.60

1.7

63.0

2

1

⁄

2

2.875

+0.029

-0.029

0.625

0.344

2.720

-0.018

0.078

0.083

2.980

65

73.0

+0.74

-0.74

15.88

8.74

69.09

-0.46

1.98

2.1

75.7

3

3.500

+0.035

-0.031

0.625

0.344

3.344

-0.018

0.078

0.083

3.600

80

88.9

+0.89

-0.79

15.88

8.74

84.94

-0.46

1.98

2.1

91.4

3

1

⁄

2

4.000

+0.040

-0.031

0.625

0.344

3.834

-0.020

0.083

0.083

4.100

90

101.6

+1.02

-0.79

15.88

8.74

97.38

-0.51

2.11

2.1

104.1

4

4.500

+0.045

-0.031

0.625

0.344

4.334

-0.020

0.083

0.083

4.600

100

114.3

+1.14

-0.79

15.88

8.74

110.08

-0.51

2.11

2.1

116.8

5

5.563

+0.056

-0.031

0.625

0.344

5.395

-0.022

0.084

0.109

5.660

125

141.3

+1.42

-0.79

15.88

8.74

137.03

-0.56

2.13

2.8

143.8

6

6.625

+0.063

-0.031

0.625

0.344

6.455

-0.022

0.085

0.109

6.730

150

168.3

+1.60

-0.79

15.88

8.74

163.96

-0.56

2.16

2.8

170.9

8

8.625

+0.063

-0.031

0.750

0.469

8.441

-0.025

0.092

0.109

8.800

200

219.1

+1.60

-0.79

19.05

11.91

214.40

-0.64

2.34

2.8

223.5

10

10.750

+0.063

-0.031

0.750

0.469

10.562

-0.027

0.094

0.134

10.920

250

273.1

+1.60

-0.79

19.05

11.91

268.27

-0.69

2.39

3.4

277.4

12

12.750

+0.063

-0.031

0.750

0.469

12.531

-0.030

0.109

0.156

12.920

300

323.9

+1.60

-0.79

19.05

11.91

318.29

-0.76

2.77

4.0

328.2

T

B

D

C

OD

Flare

A

OUT OF ROUNDNESS:

Difference between

maximum O.D. and minimum O.D. measured

at 90° must not exceed total O.D. tolerance

listed (reference column 2).

FOR IPS PIPE,

the maximum allowable tolerance

from square cut ends is 0.03" for 2" thru 3

1

⁄

2

";

0.045" for 4" thru 6"; and 0.060" for sizes 8"

and above measured from a true square line.

BEVELED-END PIPE

in conformance with ANSI

B16.25 (37

1

⁄

2

°) is acceptable, however square cut

is preferred.

GROOVE SPECIFICATION - STEEL