10

There are no predetermined maintenance intervals for this appliance

however the following should be observed.

1. Inspect hoses and replace if they are not in order, before us

ing the appliance as cracked and perished hoses can be

dangerous replace if necessary with hoses as detailed in point 5.

2. Allow the appliance to cool sufficiently before attempting any

maintenance.

3. The appliance is fitted with a jet to regulate the correct amount

of gas. The small hole in the jet may become blocked, result

ing in a small flame or no flame on the burner. To clean, unscrew

it from the appliance Clean the jet by blowing the hexagon end,

or by using a jet cleaner. Do NOT attempt to clean the jet with

a sharp object, as this will damage the very small jet aperture

and cause the appliance to malfunction. If the jet still does not

function, replace it with a new jet of the correct size. To

re-assemble, reverse the above procedures.The same procedure

applies if the pilot burner jet becomes blocked

4. Check that the flexible hose is completely connected over the

nozzles at each end of the tubing and that it is held firmly in

place by hose clamps. Examine the flexible hose regularly, at

least each time the gas cylinder is changed and ask your dealer

to fit a new LPG hose if it becomes perished, worn or damaged.

5. Only LPG hose that complies with SANS 1156-2 or BS 3212 may

be used with this appliance.

6. Trouble Shooting

• A normal flame is blue and may have an orange or yellow tip. If

the flame is completely yellow, it may be that the jet is not

securely fitted. Re-tighten to give a gas tight seal. An over-filled

gas cylinder can also cause large yellow flames. Cylinder should

be returned to filling station and checked by weight.

• Check that the primary air supply apertures in the burners are

clear and free of obstructions.

• If the flame power drops or the gas will not light, check that the

gas cylinder still contains gas (shake to hear the noise made by

the liquid).If there is still gas,the jet might have become blocked

or partially blocked.

• If you suspect a blocked jet, follow the instruction in Section 3

above.

MAINTENANCE

3

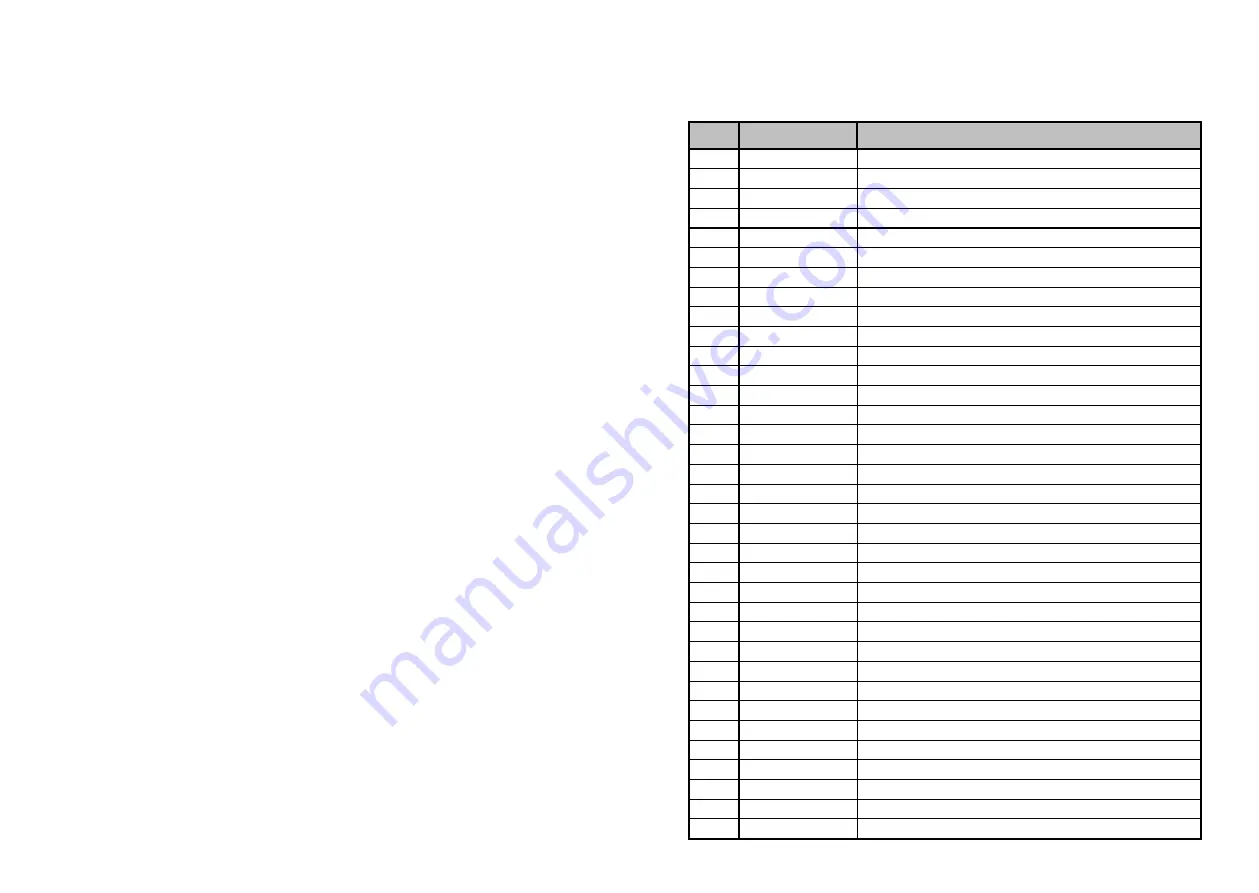

Part

SCE

No.

Part No.

1

3-KNOB-TOAST

HANDLE ADJUSTING SCREW

2

82-ARM-SS-HPOST

HANDLE HINGE BRACKET

3

82-ARM-SS-HFSHD

HANDLE FRONT SHIELD

4

7-PANINI-SPRING

HANDLE SPRING

5

14-M5/50-EB-MS

M5 PLATED EYE BOLT

6

7-PAN-BOTTOM-1

ALUMINIUM BOTTOM CASTING

7

82-ARM-MS-SSBKT

SPRING BRACKET

8

7-FCUP-TOASTER

DRIP CUP

9

3-GH-FFA3010

8MM GAS HOSE 1 METER LENGTH

10

7-BNR-LPG

BULL NOSE REGULATOR

11

82-TSG9-SS-BDYAS

BODY ASSEMBLY

12

7-FOOT-FTA7016

GRILLER ADJUSTABLE FOOT CASING

13

82-TSG9-MS-BOTCV BOTTOM COVER GALVANISED

14

82-TSG9-HSHLD

BURNER HEAT SHIELD

15

4-DL-L-AXIS

DOMED LOGO LARGE ANVIL AXIS

16

82-TSG9-SS-BBKT

BURNER BRACKET

17

7-CS-TSA9209

COOLING SPACER

18

7-BURNER-TSA9209 TSA9209 U BURNER

19

7-MAN-TSA9209-A

INLET MANIFOLD

20

7-SV-GGA0004

SAFETY VALVE GGA0004

21

82-NGC-SS-MCLMP

MANIFOLD CLAMP

22

3-KNOB-APEX

CONTROL KNOB APEX

23

3-KI-APEX

CONTROL KNOB INSERT FOR GAS VALVE

24

7-MAN-TSA9209-B

FRONT CROSS MANIFOLD

25

7-CV-GGA0004

CONTROL VALVE GGA0004

26

7-JET-TSA9209-LPG

JET

27

7-TC-GGA0004

THERMOCOUPLE GGA0004

28

7-REG-ADP

ANGLE GAS PIPE BRASS CONNECTOR

29

3-TOASTER-HAND

PLASTIC TOASTER HANDLE

30

82-ARM-SS-HAFRT

STAINLESS STEEL HANDLE

31

82-ARM-SS-ASSEM

9 SLICE TOASTER ARM

32

6-TOASTER-HS

TOP HINGE AXLE M8

33

81-TS9-9S-LID

PRESSED TOASTER STAINLESS STEEL LID

34

6-TOASTER-LS

M5 HEX SPACERS

35

7-PAN-TOP-1

ALUMINIUM TOP CASTING PANINI

MODEL: 9 SLICE PANINI NON-STICK GAS TOASTER

MODEL CODE : TSA9209

Description

REV.1