Aode Machinery Co., Ltd Page 18 of 26

奥德机械有限公司

2012

7.1

开机(

Startup

)

7.1.1

打开冷却水及循环水的阀门。

Turn on the valves of cooling water and circulating water.

7.1.2

将温度设定在

0

℃,打开电源。

Set the temperature at 0

℃

, and turn the power on.

打开电源后,可能产生以下情况:

The following situations may occur when power is on:

A

):泵浦是否反转。

Whether the pump reversal.

处理:关闭电源,将外部三相电源线中任意两相对换位置,接回即可。

Solution: Turn the power off and change the locations of any two of the three-phase

power wires, connect again.

B

):有无缺水警报。

Whether there is water shortage alarm.

处理

:

检查冷却水阀门是否开启,或是供水压力不足。

Solution: Check if the cooling water valve is on or if the pressure of water supply is

enough.

7.1.3

机器开机后,可能产生以下情况:

When the machine is on, the following situations may occur:

A

):泵浦是否过载(有警报)。

Whether the pump is overloaded (alarm)

处理:请压下马达热继电器之复归按钮,并检查三相电源是否欠相。

Solution: Please press the reset button of the motor thermal relay and check if the

three-phase power supply is default phase.

※

更换新模具时,请先排气,以增加加热器寿命。

When replace new molds, please cooling first to increase the service life of heater.

本机热水出入口各有

2

个球阀,开机后请将冷却水入口球阀打开,可将其中一个管路松

2-3

牙上的油压接头让气体排出,待有水出来再关球阀,再开机。

There are two ball valves in the hot water outlet/inlet, respectively. Please open the cooling

water inlet ball valve after starting up. And oil-pressure coupler of one pipeline can be

loosened to eliminate air. Turn off the ball valve when water flows out, and then turn the

machine on.

7.2

关机(

Turnoff

):

1

、先将温度降到

80

℃以下,再关电源。

Descend the temperature below 80

℃

first, then turn off the power.

2

、若长时间不使用,请将所有球阀打开泄放系统内之循环水。

If the machine is not in use for a long time, please open all ball valves to discharge

circulating water.

3

、北方地区视实际天气情况,需及时泄放机器的循环水和冷却水,否则会因水严重冰冻,

损坏机器设备,请密切注意。

Base on local weather in the north of China, we need to open all of the valves to discharge

circulating water and cooling water, otherwise it will damage machine in reason of serious

frost, please take noted!

Summary of Contents for AWM-05

Page 10: ...Aode Machinery Co Ltd Page 9 of 26 2012 4 2 Pump performance curve...

Page 11: ...Aode Machinery Co Ltd Page 10 of 26 2012...

Page 15: ...Aode Machinery Co Ltd Page 14 of 26 2012 5...

Page 22: ...Aode Machinery Co Ltd Page 21 of 26 2012...

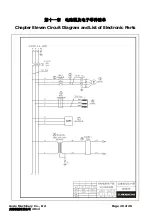

Page 26: ...Aode Machinery Co Ltd Page 25 of 26 2012 Chapter Ten Pipeline System Chart...

Page 28: ...Aode Machinery Co Ltd Page 27 of 26 2012...

Page 29: ...Aode Machinery Co Ltd Page 28 of 26 2012...

Page 30: ...Aode Machinery Co Ltd Page 29 of 26 2012...

Page 31: ...Aode Machinery Co Ltd Page 30 of 26 2012...