12

4-MIG350MC

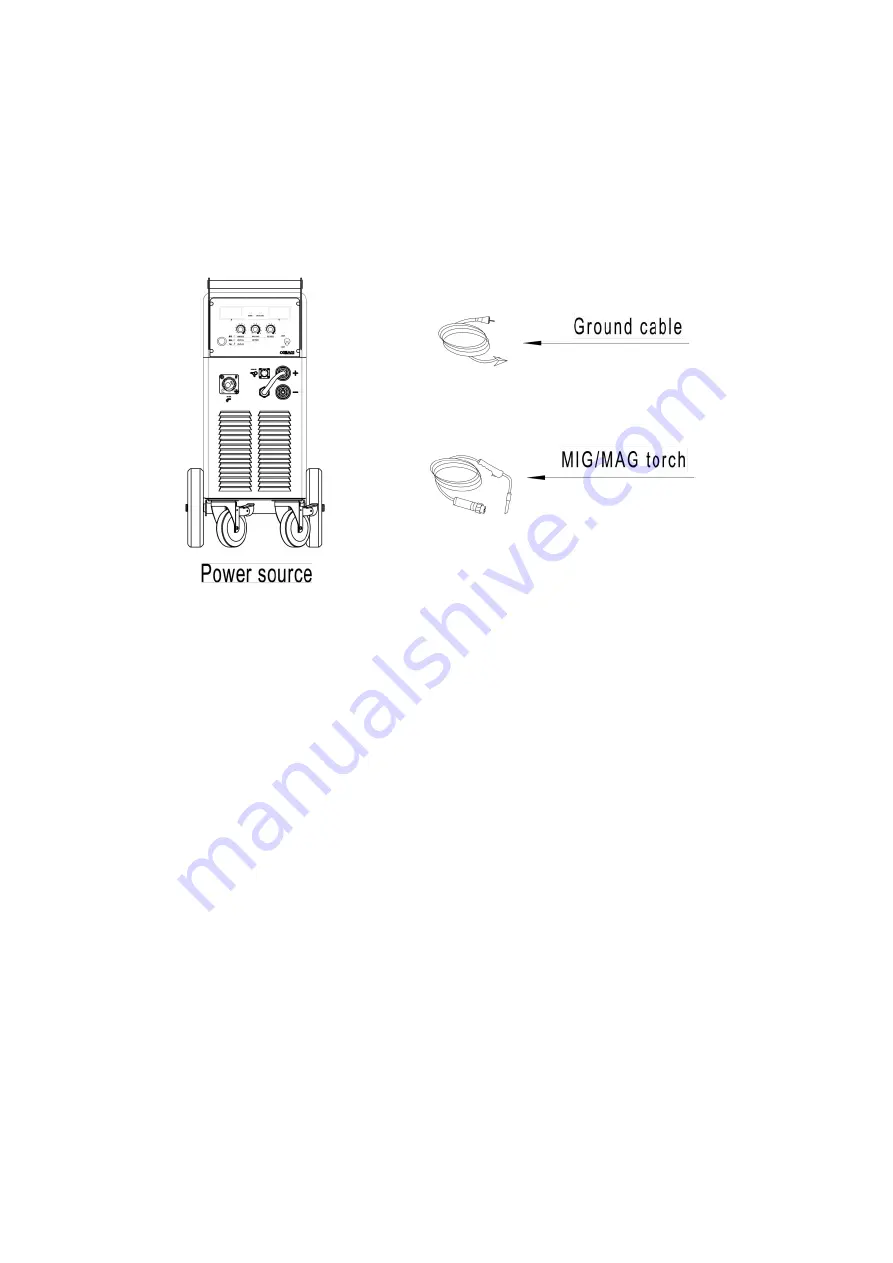

4-1 System components

This series of machines can be equipped with many different accessories and can be used in various special sites with

different configurations.

Fig. 4-1-1: System components

4-2 Basic equipments for welding

Basic equipments are needed for normal welding. Below are the lists:

MIG/MAG welding

-

Power source

-

Ground cable

-

MIG/MAG welding torch

-

CO2 gas regulator, gas hose, gas cylinder (to supply the machine with shielding gas)

-

Welding wire

STICK

-

Power source

-

Ground cable

-

Electrode holder

-

Electrode

TIG

-

Power source

-

Ground cable

-

TIG torch

Summary of Contents for MIG350MC

Page 1: ......

Page 27: ...26 Daily maintenance Fig 7 1 Daily maintenance Ver 20210506 ...