17

G

pour the sanitizing solution into the water tank

and carry out 5 working cycles of 5 minutes

each, at 5 minutes interval, letting the solution

run through the whole machine (taking care

to shut off water at the mains first);

drain the sanitizing solution off the machine;

disassemble once again all removable parts

and rinse them with clean water;

rinse also evaporator (Fig. 7 Part. 10), ice bin

(Fig. 7 Part. 9) and water tank (Fig. 8 Part.

15);

go through a couple of working cycles with

clean water before you start making ice.

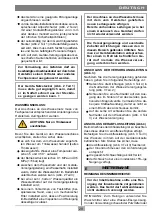

CLEANING SOLENOID-VALVE FILTER

The operator must clean the filter on the water

supply pipe (Fig. 9 part 2) every two months in

accordance with these instructions:

switch off the appliance (Fig. 2 Part 2) and

then unplug it;

shut off the stopcock (Fig. 3 Part 1);

loosen the threaded nut of the water supply

pipe (Fig. 9 Part 1);

identify and extract the filter (Fig. 9 Part 2)

from its seat without damaging the water-

supply pipe fitting;

wash the filter under a jet of running water to

remove all residual dirt;

check the wear of the filter and replace it if it

is damaged or in poor condition;

refit the filter and the water supply pipe but

do not overtighten;

at the end of the operation, restore the appli-

ance’s power and water supplies.

If the appliance is

NOT GOING TO BE USED

for

some time, for example during the winter:

switch off the appliance (Fig. 2 Part 2) and

unplug it;

shut off the stopcock (Fig. 3 Part 1);

clean and disinfect the appliance thoroughly

(see routine maintenance operations);

empty the pump body by blowing compressed

air through the water supply pipe towards

the sprayers.

SPECIAL MAINTENANCE

Special and routine maintenance must be carried

out only by qualified persons on the customer’s

premises or at the Authorised Service Centres.

ENGLISH

H

We recommend that you ask your dealer for a

‘Routine Maintenance Agreement’, which will com-

prise:

condenser cleaning (standard models):

condenser cleaning (models with air conden-

sation);

cleaning filter in water supply pipe;

cleaning production cell and ice-cube collec-

tion tray;

checking gas in cooling system;

checking operating cycle;

complete disinfecting of appliance.

TROUBLESHOOTING

If the appliance does not start up or if ice produc-

tion is interrupted, before contacting the Author-

ised Service Centre make the following checks:

electrical system:

make sure that the plug

has been correctly inserted and that the

switch (Fig. 2 Part 2) and the pushbutton (Fig.

5 Part 1) are both in the ‘ON’ position

water system:

make sure that the stop-

cock (Fig. 2 Part 3) is ‘OPEN’;

air or water temperature:

should be within

range indicated in point D;

excessive noise:

check for contact with

furniture or sheet metal that could cause noise

or vibrations;

water leaks:

make sure that the discharge

is not blocked, the water-supply pipes are

correctly connected and that they are not

crushed or damaged;

the water solenoid valve filter:

make sure

also that is not clogged up;

the sprayers:

make sure that they are not

clogged up with scale or impurities.

If problems persist, make the appli-

ance completely safe by disconnect-

ing electric and water supplies and

contact the nearest Authorised Serv-

ice Centre. Quote the product model

shown on the rating plate.