13

CLEANING AND MAINTENANCE OF THE MACHINE

OPERATE ALWAYS WHEN THE MACHINE IS STILL

The crumbs inside the slicer must not be removed when the

machine is working. Don’t use jet of water or other products. To

use a puff of air.

During the maintenance operations, the machine has not to

be connected to the electric supply mains. The replacement of

parts, the mending of damages to the electric system etc.

have to be executed by the specialised personal

If the machine is in warranty period, inform the Manufacturing firm

TENSION OF THE BELT

Disassembled the frontal panel. Besides it is possible to see the placement of the

motor and of the belts. The tension of the belts is realised by means of the clamp

which is in evidence and of the four screws. When the tension is reached, place at the

proper place the frontal panel

SUBSTITUTION OF THE BLADES

For disassembling the blade, unscrew the nut M8, unscrew the dowel and the blade

goes out. For assembling to thread the blade from the bottom with the pin. Screwing

the dowel we push the hooks up to the correct tension of the blade. then screw the nut

M8

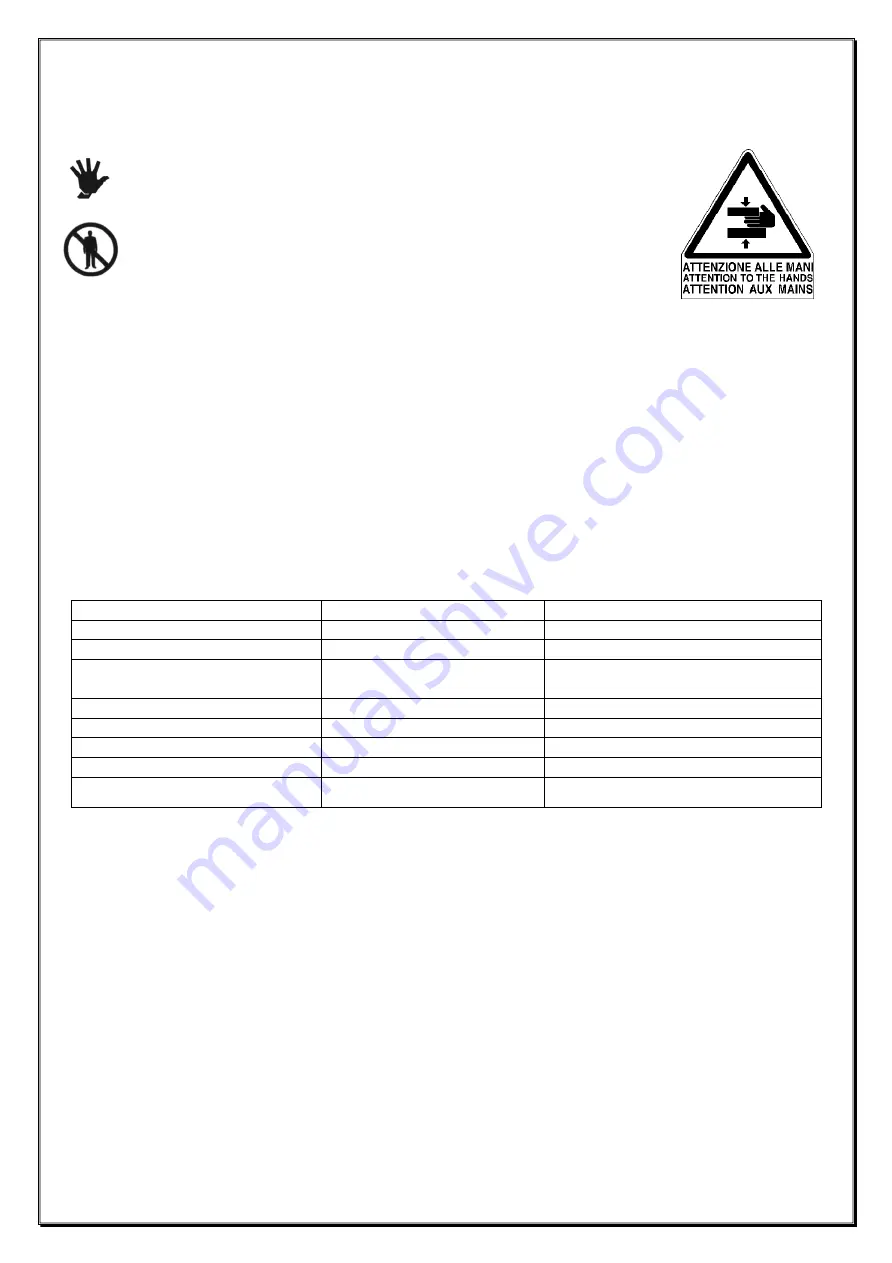

POSSIBLE DEFECT AND SOLUTIONS

The machine does not start

The plug is not connected

connect the plug

The machine does not start

Motor protection

Wait the cooling of motor protection

The machine does not start

Fuse in the cabinet melted

Change it

The machine does not start

The emergency button is

connected

Turn it as indicated from the arrow

of the emergency button

Slices irregular in thickness

Blades are not tight

Tighten the blades but not to much

The bread vibrates in the blades Frames not aligned

Align the frames

The bread vibrates in the blades Upper conveyor

Correct the height

The bread is sliced too slowly

The blades are blunt

Replace the blades

The bread is sliced too slowly

Speed conveyor

Adjust the speed

BAG-OPENING BLOWER SYSTEM (APR

)

Before connecting the “APR” check that the voltage of the machine (see the plate of the

machine) matches the voltage of your mains network. You can fix it on right or on left side of the

machine.

Adjust the bag-closer in conformity to the width of the loaf and of the bags. Put the bags under

the bag-closer, turn the button so that the bag inflates. You must help with the hand ,the inflating

of the first bag

.

FUN SYSTEM MOTORS ROLLERS

“VENMONDIAL”

The MI 52 must work at max. 25° C and we suggest the optional VENMONDIAL in way to fun the

machine. The motors rollers have to be removed every 1.000.000 cuts

SCRAPING OF THE MACHINE

The structure of the machine is made of plate enamelled with powder enamel or with two-

components epoxide enamel. The protections, the working plan, the pressing device, the

bread pusher and the knives are made of stainless steel AISI 304. The belts are made of

rubber. The electric parts are made of plastic material. For scraping, disassembled the

machine into its parts of different material which have to be delivered, together with the

hydraulic oil and the lubrification grease, to the competent elimination

Summary of Contents for Bakery Line MI52

Page 1: ...OPERATING MANUAL MI52 AUTOMATIC SLICER...

Page 2: ...RU 2 1 2 3 1...

Page 3: ...RU 3 2 3 4 5 6 7 8 ISO 11201 1 6 1 70 CEI...

Page 6: ...RU RU 6 13 4 M8 30 000 APR APR APR...

Page 7: ...RU RU 7...

Page 8: ...EN 8...

Page 14: ...14 Equip Group 125080 2 7 495 234 00 33 http equipgroup ru http bakeryline apach it...