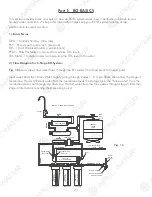

15

Stage

1

st

Stage

2

nd

Stage

3

rd

Stage

4

th Stage

4

th

Stage

6

th

DRAIN

LINE

1

st

Stage - Sediment pre-

r

2

nd

Stage - Carbon block pre-

r

3

rd

Stage - Carbon block pre-

r

4

th

Stage - Membrane

5

th

Stage - UV light

6

th

Stage - Inline carbon

r

WASTE WATER

INPUT WATER

DRINKING

WATER

TO ICEMAKER OPTION

W

G

H

A

Z

Y

DRINKING WATER FAUCET

SINK

Option 1 Diagram

Stage

5

th

Fig. 11A

Details on Tubing Connections:

To ensure a smooth and correct installation, please connect the water lines

following the sequence and

order

outlined below. Refer to

Fig.11 & 11A

for proper point locations.

1. Point Z - Faucet connection:

Tubing color: Clear tubing. The tubing already attached into RO faucet, no installation needed.

Option (Faucet comes without tubing attached) :

Tubing color: Clear tubing. Connect the CLEAR tubing to the base of RO faucet.

Fitting type: See

Fig. 9B (Page 12).

Metal compression nut fitting. Use

plastic sleeve.

Add

“insert”

to tubing. No teflon tape here. Tighten nut with wrench.

2. Point X - Feed water connection:

Important:

Insert and sleeve MUST be installed to prevent water leaking. Metal compression nut must be

fully tightened! (See

Page 8

)

Tubing color: Red tubing. Connect the RED tubing to the Feed Water Needle Valve.

Fitting type: See

Fig. 5C (Page 8).

Metal compression nut fitting. Use

plastic sleeve.

Add

“insert”

to tubing. No teflon tape here. Tighten nut with wrench.