Updated 6/16/2016

Copyright Apeks LLC, 2014

17

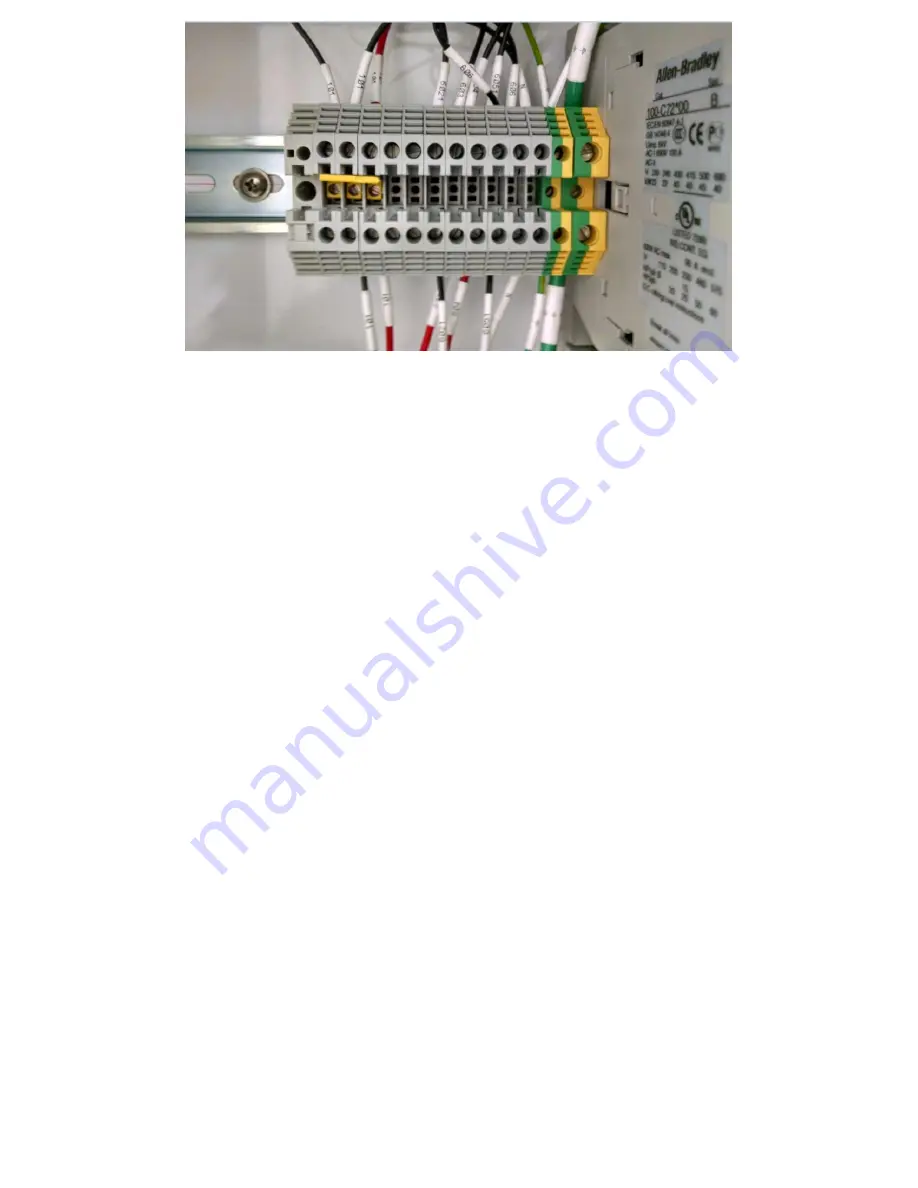

Figure 21. Pressure switch wiring from Diaphragm compressor to the Apeks system

3.1.9.

Plug the extraction system control panel into a 110-V, 15-A, standard outlet.

3.1.10.

Have a local electrician field wire the diaphragm pump and 1.5 HP Polyscience

chiller with the appropriate connections.

3.1.11.

Have a local electrician field wire the diaphragm pump and ¾-HP Polyscience

chiller with the appropriate connections.

3.1.12.

Do NOT plug anything into a GFI outlet.

Chiller/Heater Setup

3.1.13.

Wire the chiller per the specs listed for the appropriate model in the electrical

section.

3.1.14.

Plug the chiller into a 220-V, 15-A, NEMA 6-15R receptacle for ¾ HP Chillers

3.1.15.

Coolant fluid (50/50 mix of distilled water and propylene glycol DO NOT USE

DEIONIZED WATER) is added to the system through the reservoir cap on the top of

the chiller.

3.1.15.1. On the initial fill the chiller will pump contents of the reservoir into the system

which will require additional fluid to be added until the system (water jackets and

hose) are full.

3.1.15.2. After the system is operational, recheck the coolant level (while the system is

running) and add more coolant as necessary.

3.1.16.

Adjusting your system between Fahrenheit and Celsius doing the following:

3.1.16.1. Turn the circuit breaker on the back of the system to the off position.

3.1.16.2. Press and hold the menu button on the front of the chiller (button on the left).

3.1.16.3. Turn the circuit breaker back on

. The display should show “dF” or “dC”

depending which was previously selected.

3.1.17.

More detailed operating instructions for the heater/chiller can be found in the

manufacturer’s operating instructions.

Summary of Contents for 2000 PSI Series

Page 49: ...Updated 6 16 2016 Copyright Apeks LLC 2014 49 ...

Page 50: ...Updated 6 16 2016 Copyright Apeks LLC 2014 50 Appendix C CO2 Phase Diagram ...

Page 51: ...Updated 6 16 2016 Copyright Apeks LLC 2014 51 ...

Page 52: ...Updated 6 16 2016 Copyright Apeks LLC 2014 52 Appendix D Training Process ...