Updated 6/16/2016

Copyright Apeks LLC, 2014

39

This maintenance schedule is based on the maintenance timer on the Maintenance Screen (see

Figure 31).

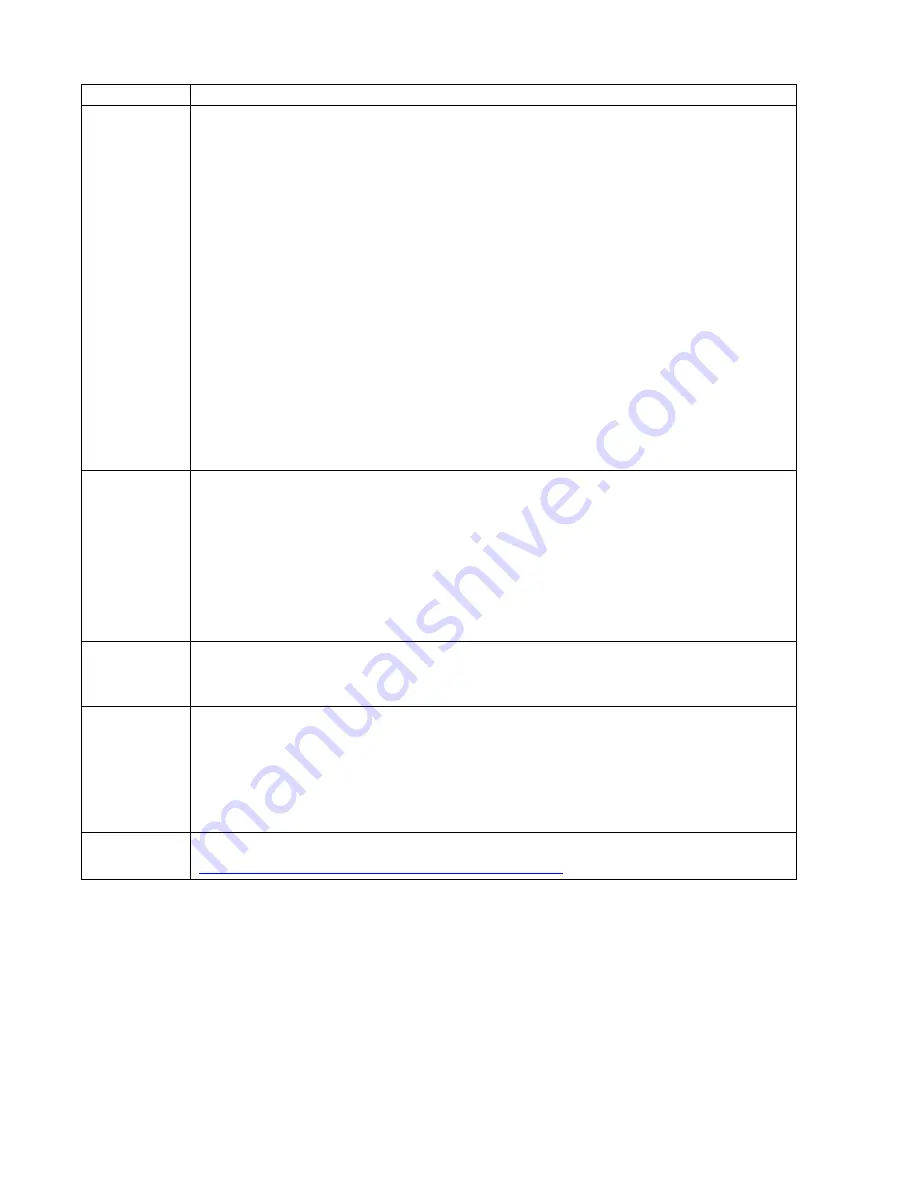

Frequency

Maintenance Item

After Each

Extraction

Remove extracted oil from collector cup and separator 1 walls, clean

walls and cup with alcohol.

Check separator 2 for oil carryover and clean if necessary.

Check orifice for clog

Inspect separator gaskets and grooves prior to reassembly.

Clean piping between separator 1 and 2 with alcohol.

Clean Separator 2 outlet to pump inlet, ensure valve 11 is open.

Remove spent material from the extraction vessel by vacuuming it out

through the top flange, be careful to not damage temp probe.

Verify the extractor filters are clear and free of debris

Load material unless conducting a dry run.

Check extraction vessel O-rings and O-rings groove sealing surfaces for

damage

– replace if necessary

Inspect the threads on the extraction vessel(s) and ensure the threads

are free of debris and are properly greased with the provided bottle of

anti-seize

(failure to apply anti-seize will result in damaged threads

which could cause injury and void the systems warranty)

Every 80

hours

Check chiller/heater water level is between min and max line on back of

chiller.

Clean all flexible metal lines going into and out of both separators.

Clean CO

2

flow lines between the pump and the coiled heat exchanger

with alcohol. Flow lines must be disconnected from pump and

extraction system to thoroughly clean.

Run the system “empty of plant material” for 1 hour to clean the high

pressure side of the system and extraction vessel(s)

Every 160

hours

Check belt tension on diaphragm compressor.

(See page 42 & 43)

Unscrew the bottom extraction vessel(s) to clean and inspect the

temperature probe(s) and filter(s).

Yearly

Schedule yearly maintenance with an Apeks Service Engineer to come

onsite and replace seals in Diaphragm compressor and perform a yearly

inspection on the system. Please notify the Apeks service department

one month in advance, and notify the service engineer of any issues

prior to the visit.

To schedule, call 740-809-1171

Resource

Apeks online store

http://www.apekssupercritical.com/online-store/

Summary of Contents for 2000 PSI Series

Page 49: ...Updated 6 16 2016 Copyright Apeks LLC 2014 49 ...

Page 50: ...Updated 6 16 2016 Copyright Apeks LLC 2014 50 Appendix C CO2 Phase Diagram ...

Page 51: ...Updated 6 16 2016 Copyright Apeks LLC 2014 51 ...

Page 52: ...Updated 6 16 2016 Copyright Apeks LLC 2014 52 Appendix D Training Process ...