Updated 6/16/2016

Copyright Apeks LLC, 2014

53

In preparation of training,

Please refer to the manual for unpacking and setup instructions. Below is a check list of what needs to be purchased or

completed BEFORE scheduling your onsite training. Onsite training is a four hour block of instruction that is NOT

designed to include unpacking and set-up. Incomplete items at the time of onsite training will result in incomplete

training or additional charges for rescheduling.

Our training process is as follows:

1.

Customers to reference Apeks manual for instructions on un-crating and system setup

2.

Customer to complete entire Pre-Training Checklist

3.

A Face Time or Skype session is required (when available) to ensure Checklist is complete, setup is correct and

the session is to cover basic operation and cleaning of the system

4.

After 1 through 3 are complete, scheduling of onsite training can occur and it will be a 2 week lead time.

Pre Training Checklist:

Below is a check list of what needs to be purchased or completed BEFORE scheduling your onsite training.

o

Must be complete before scheduling training:

Print off complete Apeks manual and have on site the day of

training, along with the manual to the chiller. Use this link for the download manual if needed,

o

Must be complete before scheduling Training:

Apeks system and diaphragm compressor are unpacked and setup

in its location of operation. Refer to unpacking instructions, Ch. 2-4, in the manual.

o

Must be complete before scheduling training

: Insure you have the following electrical receptacles

o

independent 220V, 15A, 1 phase NEMA 6-15R receptacle for the chiller/heater (i2000)

o

independent 220V, field wired 40A dedicated circuit 1.5 HP chiller (2000 production series)

o

independent 110V, 15A, 1 phase NEMA 5-15R receptacle for the systems controller, surge protector

recommended

o

Must be complete before scheduling training

:

Consult with a commercial electrician.

o

7.5 HP Diaphragm Compressor

o

Install a fused disconnect with AJT70 dual element, time delay fuses for a 7.5HP motor branch

circuit. See the chart below for more details

o

12.5 HP Diaphragm Compressor

o

Install a fused disconnect with AJT90 dual element, time delay fuses for a 15HP motor branch circuit.

See the chart below for more details.

o

Please have your commercial electrician contact the Director of Engineering if they have questions

concerning the diaphragm compressor electrical connections at

jeremys@apekssupercritical.com

o

If you have a used or refurbished system, or if you want to use 3 phase power, please contact

our Director of Engineering

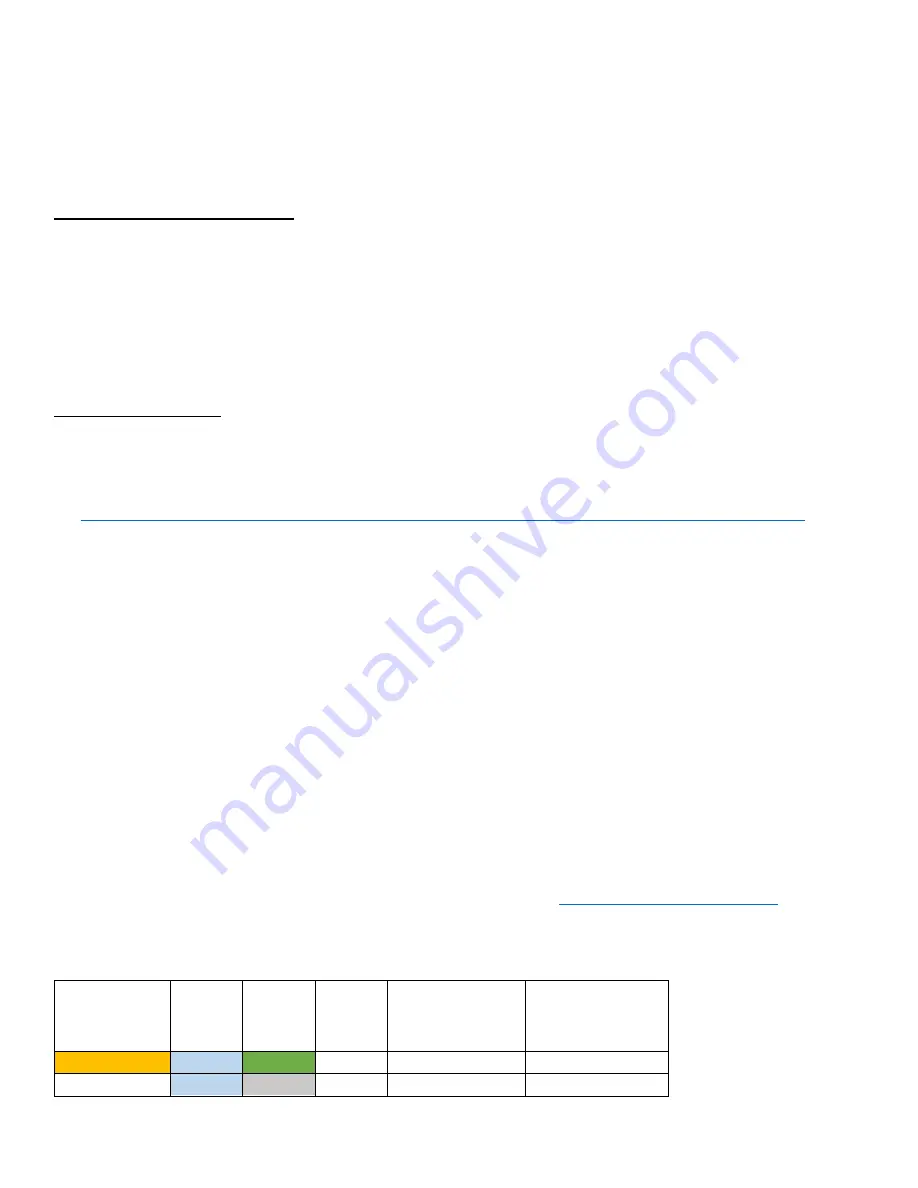

Compressor

Motor HP

Phase Voltage

Motor

FLA

Recommended

Fuses where

field wired

Compressor mfg

and model

12.5

1

230V

48A

AJT90

2000 Production

7.5

1

230V

40A

AJT70

2000 Introductory

Summary of Contents for 2000 PSI Series

Page 49: ...Updated 6 16 2016 Copyright Apeks LLC 2014 49 ...

Page 50: ...Updated 6 16 2016 Copyright Apeks LLC 2014 50 Appendix C CO2 Phase Diagram ...

Page 51: ...Updated 6 16 2016 Copyright Apeks LLC 2014 51 ...

Page 52: ...Updated 6 16 2016 Copyright Apeks LLC 2014 52 Appendix D Training Process ...