Cleaning Brass and Stainless Steel Parts

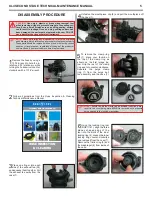

1. Preclean in warm, soapy water* using a soft nylon bristle brush.

2. Thoroughly clean parts in an ultrasonic cleaner filled with soapy water. If there are stubborn deposits, household white distilled

vinegar (acetic acid) in an ultrasonic cleaner will work well. DO NOT place plastic, rubber, silicone or anodized aluminum parts

in vinegar.

3. Remove parts from the ultrasonic cleaner and rinse with fresh water. If tap water is extremely “hard,” place the parts in a bath

of distilled water to prevent any mineral residue. Agitate lightly, and allow to soak for 5-10 minutes. Remove and blow dry with

low pressure (25 psi) filtered air, and inspect closely to ensure proper cleaning and like-new condition.

Cleaning Anodized Aluminum, Plastic & Rubber Parts

Anodized aluminum parts and parts made of plastic or rubber, such as box bottoms, box tops, dust caps, etc., may be soaked and

cleaned in a solution of warm water mixed with mild dish soap. Use only a soft nylon toothbrush to scrub away any deposits. Rinse in

fresh water and thoroughly blow dry, using low pressure filtered air.

Cleaning MP Hoses

(Air use Only)

Follow Hose Inspection & Cleaning Guidelines for more detailed information

1.

Hose fittings: Ultrasonically clean with soapy water; Use soft nylon bristle brush. If corrosion is evident, use a brass bristle brush.

2. Run water through hose if needed

3. Thoroughly rinse with fresh water

4. Blow out hose before installing

Lubrication and Dressing

Wear powderless, latex gloves when handling and lubricating o-rings. Keeping internal parts free from skin oils and other contaminates is

important when running enriched air nitrox through a first stage. All o-rings should be lubricated with Christo-Lube

®

MCG-111. Dress the

o-rings with a very light film of grease, and remove any visible excess by running the o-ring between thumb and forefinger. Avoid applying

excessive amounts of Christo-Lube grease, as this will attract particulate matter that may cause damage to the o-ring.

*Soapy water is defined as “household” grade liquid dishwashing detergent diluted in warm water.

PROCEDURE A: CLEANING & LUBRICATING

AQUA LUNG AND APEKS REGULATORS AND NITROX

When it comes to issues of nitrox safety and compatibility, the concerns lie primarily with the regulator’s first stage as it is subjected to

high inlet pressures. High inlet pressures lead to adiabatic compression or heating of the gas. The Aqua Lung or Apeks regulator product

described in this manual, when properly cleaned and assembled, is authorized for use with enriched air nitrox (EAN) that does not ex-

ceed 40% (EAN 40). It is authorized because it has undergone adiabatic compression testing and the authorized service kit components

and lubricants are compatible in elevated oxygen environments. During cleaning, a mild detergent must be used to remove condensed

hydrocarbons (compressor oils) from the inside passageways of the first stage. For the first stage to remain EAN40 compatible, only use

hyperfiltered compressed gas (hydrocarbons < 0.1 mg/m3). Ordinary compressed breathing air (Grade E) usually does not meet this

criterion. Once ordinary breathing air is used, the first stage is no longer EAN40 compatible until it is cleaned and serviced again.

Although regulator second stage components are not exposed to high pressure EAN, Aqua Lung and Apeks recommend that the same

cleaning procedures be followed for the complete regulator. This prevents the possibility of cross contamination and guarantees the

cleanliness of the entire regulator.

CAUTION:

Do not place plastic and rubber parts in contact with acid solu-

tions. This could alter their physical properties and cause degradation and

premature breakdown.

CAUTION:

Do not place complete hose length in contact with acid solu-

tions. This could alter their physical properties and cause degradation

and premature breakdown.

18