WARNING:

Flooding may occur if the tail of the valve is not

fully pulled through. Ensure that the barb has engaged on

inside of case.

REASSEMBLY PROCEDURE

NOTE:

Before performing any reassembly, it is important to inspect

all parts, both new and those that are being reused, to ensure that

every part and component is perfectly clean and free of any dust,

corrosion, or blemishes. Before dressing each o-ring with Christo-

Lube

®

, check to ensure it is clean, supple, and free of any blemish.

WARNING:

Use only genuine Apek's

®

parts, sub-assemblies,

and components whenever assembling any Apek's

®

product.

DO NOT attempt to substitute an Apek's

®

part with another

manufacturer’s, regardless of any similarity in shape, size or

appearance. Doing so may render the product unsafe, and

could result in serious injury or death.

1

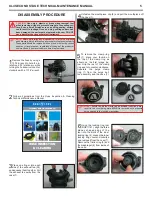

If replacing the exhaust valve (25) thread the tail through the

retaining hole on the outside of the case (7) until the barb en-

gages on the inside. Cut off the excess stem with side cutters leaving

approximately 5mm of the tail behind.

2

Install o-ring (19) onto the spring carrier (21). Check the bore

of the shuttle valve (18) to ensure that the old o-ring has been

removed. Insert the spring carrier into one end of the spring (20)

and the shuttle valve into the other, carefully guiding the end of the

spring carrier into the bore of the shuttle valve.

3

Carefully place the spindle

adjuster sleeve (22) on the

spring carrier (21). Ensure that

the two legs of the spindle ad-

juster sleeve correctly line up

with the slots in the spindle body

(16). Check the spindle adjuster

sleeve passes through the slots

in the spindle body.

NOTE

:

Ensure that the lever has a full range of movement and does

not catch on the valve spindle body. Ensure that the spring can be

seen through the valve spindle hole.

CAUTION:

Ensure that lever is not twisted and that legs are

parallel. Lever should appear as that shown on the left, not

as shown on the right. If necessary, gently squeeze legs

together to straighten.

5

Carefully insert the silicone MP seat (17) into the end of the shuttle

valve (18). Ensure the MP seat is sitting flush to the shuttle valve.

6

Inspect the flat end of the mi

-

cro adjuster tool (RG911227)

and the spindle body assembly

(14-22), take note of the cutout

on the tool.

4

Position the large fin of the

spindle body (16) down.

Press the end of the shuttle valve

(18) to fully compress the spring

(20), until it passes the triangular

shaped hole in the spindle body.

Insert the feet of the lever (15)

one leg at a time into the gap, this

retains the shuttle valve inside

the spindle body.

Large Fin

Gap

8