APEN GROUP SPA reserves the right to make changes deemed to be required to its products or documentation

AH-New

condensing air handling unit

36

code HG0310.05GB ed.A-2010

AH

37

code HG0310.05GB ed.A-2010

AH

HG0131.00 A 002

HG0310.00_IM 0012

10m

CARTIGLIO cod. X07003 ed.0411

-

MODIFICA APPROVATA DA

-

APPROVATO DA

-

-

-

-

-

-

DATA MODIFICA

MODIFICA DISEGNATA DA

-

DESCRIZIONE MODIFICA

ESP

-

-

DATA

DISEGNATO DA

Rame

MATERIALE

SCALA

®

ApenGroup

Heating and Conditioning Solutions

ESP

DISEGNO

DESCRIZIONE

1:3

Quote senza indicazione di

tolleranza:

Classe di Tolleranza

ISO 2768 - M

DISEGNO DI PROPRIETA' APEN GROUP spa E' VIETATA LA RIPRODUZIONE E LA DIFFUSIONE ANCHE PARZIALE SENZA L'AUTORIZZAZIONE DELL'APEN GROUP spa

ISO 2768 - C

per lavorazioni in tranciatura

PESO G

FOGLIO

3212.57

A3

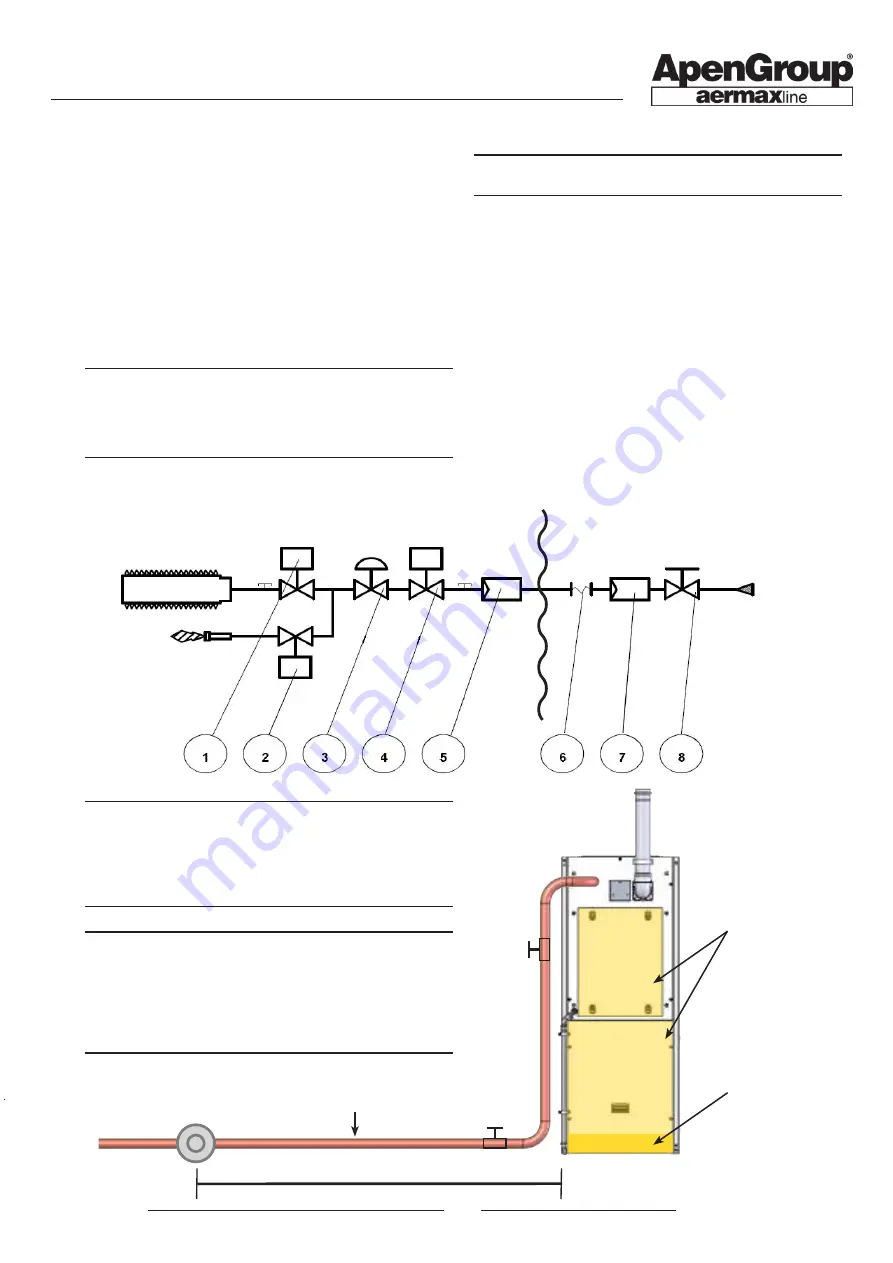

5.7.

GAS Connection

Use the gas line connections only with CE certified components.

AH modules are supplied complete with:

•

dual gas valve;

•

stabiliser and gas filter.

Al components are fitted inside the burner housing.

To complete the installation, as required by the current

regulations, the following components must be fitted:

•

anti-vibration joint;

•

gas valve;

•

gas filter.

NOTE: AN

EN126 certified gas filter with filtration level

lower than or equal to 50 microns must be used, with no

pressure stabiliser, with great capacity, since the filter

supplied as standard, upstream of the gas valve, has a

limited surface.

IMPORTANT: For proper maintenance, connect the AH

module by means of a seal and swivel gasket.

Avoid using threaded connections directly on the gas connection.

Current legislation allows a maximum pressure inside the rooms,

or thermal stations, of 40 mbar; higher pressure values must

be reduced before entering the boiler room or the site where

the AH module is installed.

KEY

1

Main burner gas solenoid valve

2

Pilot burner gas solenoid valve

3

Pressure stabiliser

4

Safety gas solenoid valve

5

Gas filter (small section)

------------------------------------------------------------------

6

Anti-vibration joint

7

Gas filter (large section)

8

Gas valve

During the installation, we recommend tightening the

external gas supply pipe nut without exceeding the

tightening torques shown below:

- Ø 3/4'':

150 Nm;

- Ø 1'':

200 Nm;

- Ø 1 1/2'':

300 Nm.

It is strictly prohibited to supply gas to the circuit with

pressure higher than 60 mbar. Such pressures could

cause the valve to break. If pressure is higher than 60mbar,

a pressure reducer must be installed at a distance of

at least 10 m and no pressure stabiliser must be fitted

between the pressure reducer and the unit, but leaving

the gas filter.

To be provided by the installer

Included with the PCH module

Max 60 mbar

Do not position the gas

duct in front of removable

panels or components to

be serviced.

Panel

REMOVABLE

Panel

REMOVABLE

Pressure

reducer

Air intake filter

section