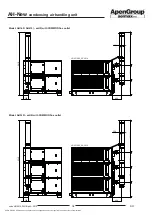

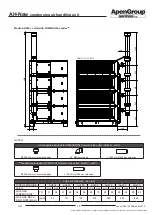

AH-New

condensing air handling unit

APEN GROUP SPA reserves the right to make changes deemed to be required to its products or documentation

40

code HG0310.05GB ed.A-2010

AH

41

code HG0310.05GB ed.A-2010

AH

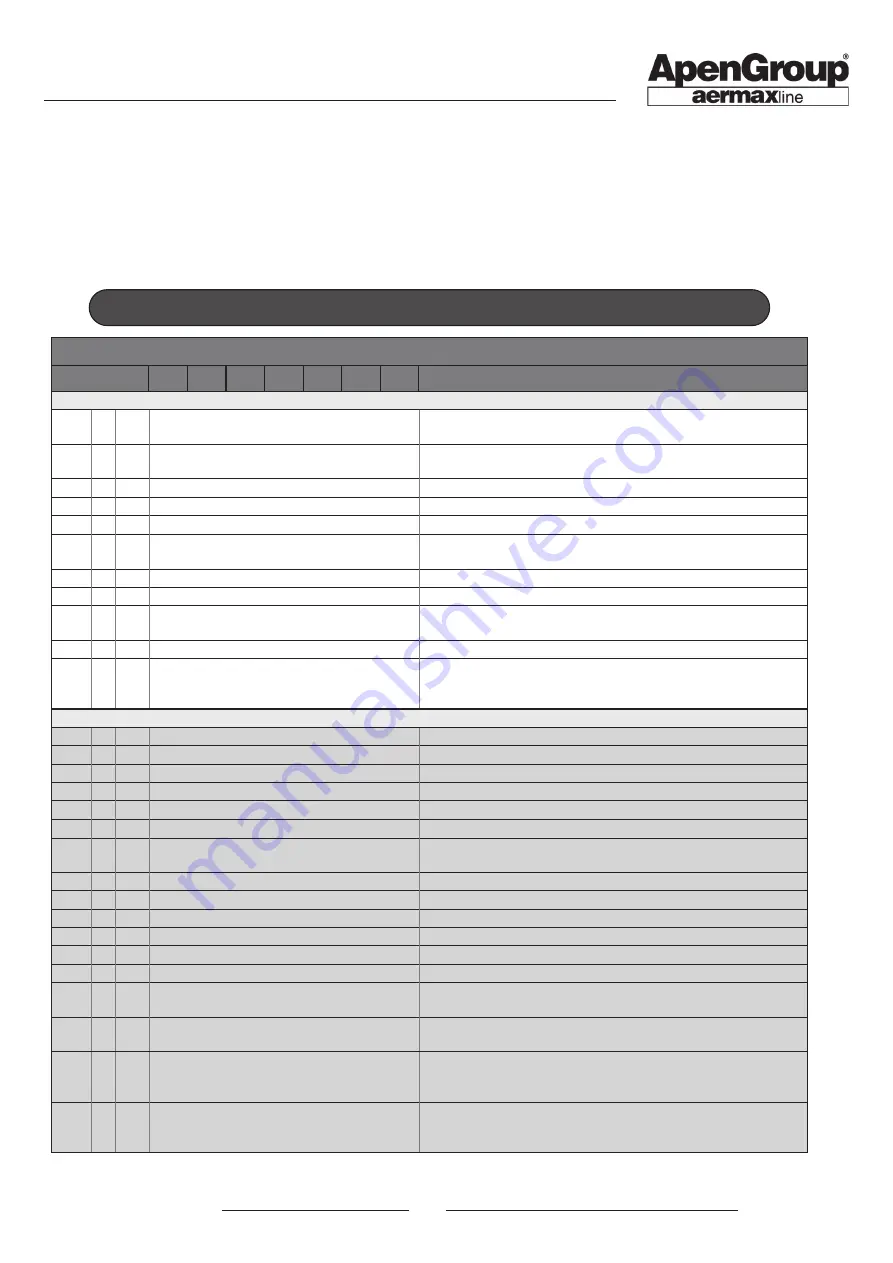

Parameters of CPU-SMART PCB version 7.03.xx

PARAMETER

AH034

AH065

AH105

AH160

AH210

AH320

AH420

DESCRIPTION

Control parameters

d0

(2)

-

7

Flame modulation: 2=NTC1; 5=0÷10Vdc; 7=Modbus (SmartWeb

in PID mode)

d1

(2)

-

8

Type of equipment: 0=heater; 2=boiler; 5=PCH; 8=PKA/E;

10=Queen; 12=Fan heater

d2

(2)

-

0

Remote lockout signal output (Q1): 0=disabled; 1=enabled

d3

(2) sec

60

Fan delay time ON (RL2): 0÷255

d4

(2) sec

30

Fan delay time OFF (RL2): 0÷255 (1=5sec. 60=300 sec.)

d5

(2)

-

0

Flue gas T control enabling (NTC3): 0=disabled; 1=enabled

NOT USED

d6

(2) sec

5

Interval between switching off and on (Off timer): 0÷255

d7

(2)

-

0

1= Fault reset counter; 2= Burner hour-meter reset

d8

(2)

-

0

Boiler antifreeze enabling (NTC1): 0=disabled; 1=enabled

NOT USED

d9

(2)

-

0

Dampers enabling: 0=disabled; Do Not Change

d10 (2)

-

0

Continuous ventilation: 0= disabled; 1= enabled (fans always

active); 2= enabled with delay par.d3 upon remote heat request

- active in Fault in case of heat request

Burner parameters NOT USED

b1

(2) rpm

300

Motor RPM MINIMUM value (PWM1): 90÷999 (1=10 RPM)

b2

(2) rpm

600

Motor RPM MAXIMUM value (PWM1): 90÷999 (1=10 RPM)

b3

(2) rpm

400

Motor RPM START-UP value (PWM1): 90÷999 (1=10 RPM)

b4

(2)

-

2

HALL signal divider: 2÷3

b5

(2) rpm

50

Error F3x; no. of revolutions x10 (50=500rpm): 0÷300

b6

(2) sec

20

Error F3x; error dwell time before fault F3x: 0÷255

b7

(2) sec

20

Pre-cleaning time with maximum output: 0÷255. DO NOT

CHANGE THE PRESET VALUE.

b8

(2) sec

10

Flame stabilisation time (ignition): 0÷255

b9

(2) sec

90

Combustion chamber post-cleaning time (FAN ON): 0÷255

b10 (2)

%

5

Motor rpm % increase for each b11 seconds: 1÷100

b11 (2) sec

2

Time interval for motor rpm increase: 1÷100

b12 (2)

%

30

Antifreeze mode FAN motor modulation % value: 30÷100

b13 (2)

pwm

65

Integral factor value (ki_pwm) for PWM1 calculation: 0÷249

b14 (2) pwm

45

Proportional factor value (kp_pwm) for PWM1 calculation:

0÷249

b15 (2) sec

0

with d1=0 or 5: delay time ON flame control equipment (TER);

with d1=2 (boiler): F85/F86 water flow delay alarm at start-up

b16 (2)

-

0

ID5 - Blower fan control: 0=input disabled; 1=enabled with N.C.

input required; 2=enabled with N.O. input required; 3= enabled

with N.C. input required with auto-reset;

b17 (2)

-

0

ID6 - Blower fan control: 0=input disabled; 1=enabled with N.C.

input required; 2=enabled with N.O. input required; 3= enabled

with N.C. input required with auto-reset;

Main modulation PCB configuration:

MASTER

6.4.

Parameters of MASTER and SLAVE modulation PCBs

All values of the parameters of the CPU-SMART PCB are shown for all AH unit models.

•

(1)

parameters that could be modified with "001” Password via remote LCD control (even with modbus address ≠ 0).

•

(2) parameters that could be modified with a second level Password which can be requested to the manufacturer's Service

Centre (even with modbus ≠ 0 address).

•

(3) parameters that could be modified only with a Smart Web or via modbus.