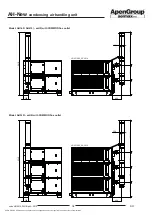

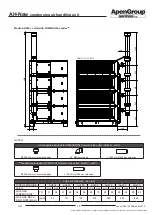

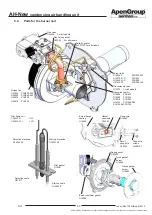

AH-New

condensing air handling unit

APEN GROUP SPA reserves the right to make changes deemed to be required to its products or documentation

44

code HG0310.05GB ed.A-2010

AH

45

code HG0310.05GB ed.A-2010

AH

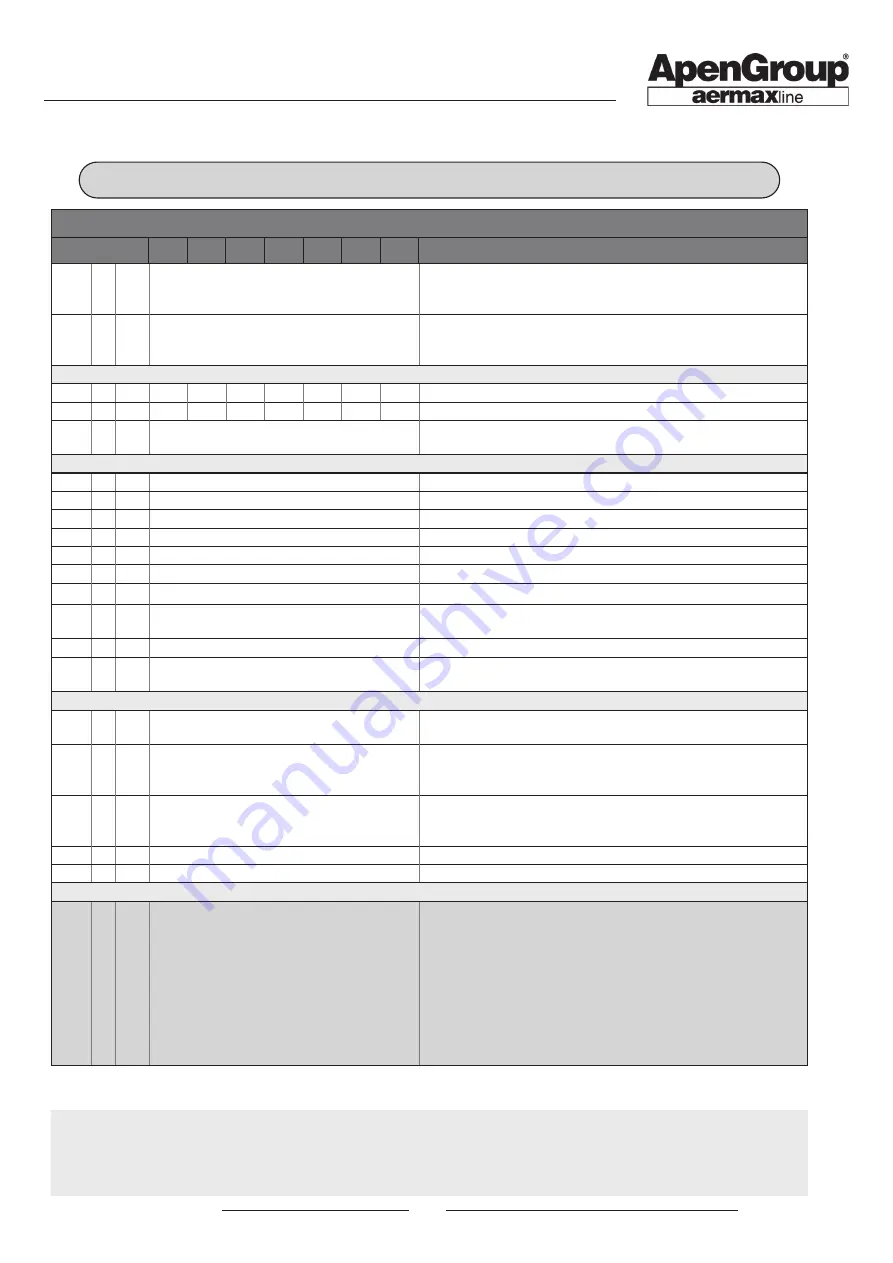

Parameters of CPU-SMART PCB version 7.03.xx

PARAMETER

AH034

AH065

AH105

AH160

AH210

AH320

AH420

DESCRIPTION

b16 (2)

-

0

ID5 - Blower fan control: 0=input disabled; 1=enabled with N.C.

input required; 2=enabled with N.O. input required; 3= enabled

with N.C. input required with auto-reset;

b17 (2)

-

3

ID6 - Blower fan control: 0=input disabled; 1=enabled with N.C.

input required; 2=enabled with N.O. input required; 3= enabled

with N.C. input required with auto-reset;

Heat input and fuel instantaneous consumption calculation parameters

(a)(b)(c)(d)

Qmin (3) kW

7.6

12.4 21.0 16.4 21.0 21.0 21.0

Minimum heat input (ref. Lower calorific value - Hi)

Qmax (3) kW 34.85 65.0 99.9 82.0 99.9 99.9 99.9

Maximum heat input (ref. Lower calorific value - Hi)

LCV (3)

kW/m

3

see table of "Gas-type parameters” here

below

Lower calorific value (Hi)

Limit NTC1 control (with D0=5 or 7)

SEL (2)

-

3

Modulation probe 1=NTC probe1; 3=NTC3 probe

S1

(2)

-

0

NTC1 probe enabling: 0=disabled; 1=enabled

ST1 (1)

°C

75

NTC1 setpoint: -10÷140

SP1 (2)

°C

5

SP1 hysteresis: 0÷10

XD1 (3)

%

20

Proportional band from 4 to 100

TN1 (3) sec

100

Integral coefficient: 1÷255

AC1 (3)

-

1

0=only modulation; 1= modulation and ON/OFF

TH1 (2)

°C

85

Upper Temperature limit for fault F51 activation: 10÷95

autoreset if NTC1<TH1-15°C

S3

(2)

-

1

NTC3 probe enabling: 0=disabled; 1=enabled

TH3 (2)

°C

85

Upper temperature limit for F53 fault activation (auto-reset if

NTC3<TH3): 0÷140

Control 0/10 Vdc - D0=5

H51 (1)

-

1

Active only with D0=5 (0/10V) 0=modulation only; 1=modulation

and ON/OFF

H52 (1)

V

0.5

OFF voltage, burner switching off if H51=1: 0÷10

1st. Module = 0.5; 2nd. Module = 1.5; 3rd. Module = 2.5; 4th.

Module = 3.5.

H53 (1)

V

0.5

Voltage Delta with burner ignition ON

1st. Module = 0.5; 2nd. Module = 1.0; 3rd. Module = 1.5; 4th.

Module = 1.5.

H54 (3) sec

10

Lower input dwell time: 0÷255

H55 (3) sec

10

Upper input dwell time: 0÷255

Fan and damper output control

H11 (2)

-

0

0=output disabled;

1=analogue output Y1 enabled (PWM);

2=analogue output Y2 enabled (0÷10Vdc);

3=outputs Y1 (PWM) and Y2 (0÷10Vdc) enabled;

4=outputs Y1 (PWM) and Y2 (0÷10Vdc) enabled for

pressostatic structures;

5=analogue output Y2 (0÷10Vdc) enabled for operating mode

d1=10/12;

6=outputs Y1 (PWM) and Y2 (0÷10Vdc) enabled for boiler

summer ventilation with EC fan heater

Secondary modulation PCB (PCH) configuration:

SLAVE

NOTES:

(a)

Models AH105, AH160, AH210, AH320 and AH420 are not approved for operation with gas G2.350 (Poland)

(b) For AH065 model, set Qmax = 57 (kW) for operation with gas G2.350 and G27 (Poland)

(c)

For AH105 model, set Qmax = 94 (kW) for operation with gas G25.1 (Hungary) and G27 (Poland)

(d)

For AH160 model, set Qmax = 75 (kW) for operation with gas G27 (Poland)