APEN GROUP SPA reserves the right to make changes deemed to be required to its products or documentation

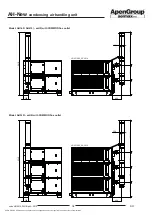

AH-New

condensing air handling unit

44

code HG0310.05GB ed.A-2010

AH

45

code HG0310.05GB ed.A-2010

AH

Parameters of CPU-SMART PCB version 7.03.xx

PARAMETER

AH034

AH065

AH105

AH160

AH210

AH320

AH420

DESCRIPTION

H12 (1)

V

4

Y2 output minimum voltage: 0÷10

H13 (1)

V

10

Y2 output maximum voltage: 0÷10

H14 (3)

%

80

PWM minimum value: 0÷100

H15 (3)

%

100

PWM maximum value: 0÷100

H16 (3)

-

2

0, 1=not used;

2=blower modulation proportional to FAN (do not change);

3=blower modulation proportional to B1 input (0-10V);

4 proportional to B2 input for pressure check in pressostatic

structures;

5= proportional NTC1 for checking Queen/Fan heaters (only

output Y2)

H17 (3)

-

1

0=PWM (Y1) or 0/10V (Y2) output according to "direct" logic;

1=PWM (Y1) or 0/10V (Y2) output according to "reverse" logic;

2= PWM (Y1) "reverse" and 0/10V (Y2) "direct” output;

3= PWM (Y1) "direct" and 0/10V (Y2) "reverse” output

H18 (1)

-

8

Y2 output fixed voltage

H19 (3)

-

32

Reading of NTC1 to which the minimum value of Y2 output

corresponds - NOT USED

H20 (3)

-

65

Reading of NTC1 to which the maximum value of Y2 output

corresponds - NOT USED

Table of "Parameter b15 for multiple module machines”

PARAMETER

SLAVE 1

SLAVE2

SLAVE 3

SLAVE 4

DESCRIPTION

b15

(2) sec

0

10

20

30

with d1=0 or 5: delay time ON flame control equipment (TER);

with d1=2 (boiler): F85/F86 water flow delay alarm at start-up

Table of "Gas-type parameters"

PARAMETER

G20

G25

G25.3

G25.1

G27

G2.350 G30 G31

DESCRIPTION

LCV (3)

kW/m

3

9.45 8.13 8.31 8.14 7.75 6.75 12.4

Lower calorific value (Hi)

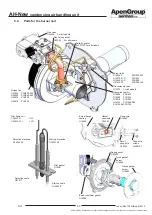

Secondary modulation PCB (PCH) configuration:

SLAVE