AH-New

condensing air handling unit

APEN GROUP SPA reserves the right to make changes deemed to be required to its products or documentation

52

code HG0310.05GB ed.A-2010

AH

53

code HG0310.05GB ed.A-2010

AH

HG0131.00 A

003

HG0131.00 A

003_A

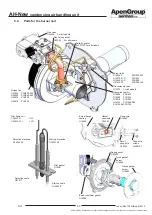

Venturi

Gas intake pressure

connector (IN)

OFFSET adjustment screw

OFFSET pressure intake

(Pascal)

CO

2

adjustment

For models: PCH020, PCH034, PCH045, PCH065, PCH080

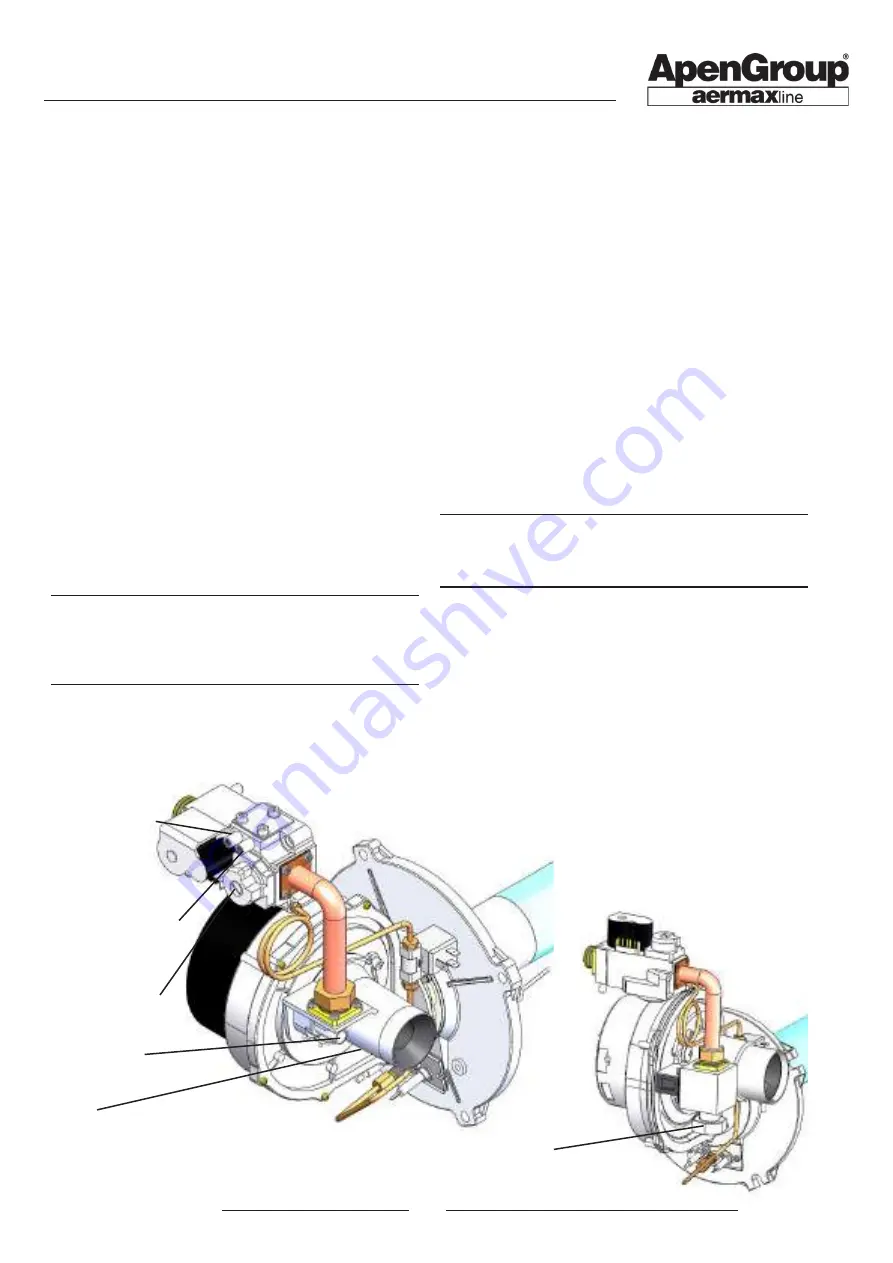

For models: PCH105

CO

2

adjustment

6.8.

S

tarting up for the first time

The PCH heater module is supplied already set up and tested

for the gas specified on the nameplate. Before turning on the

PCH module check the following:

•

make sure the gas being supplied matches the gas for which

the PCH has been set up;

•

check, with the pressure intake "IN" on the gas valve, that

the valve input pressure corresponds to that required for

the type of gas being used;

•

check that electrical connections correspond to those

indicated in this manual or other wiring diagrams enclosed

with the unit;

•

check that efficient earthing connections have been

completed, carried out as specified by current safety

regulations;

•

power on the heater with the general switch located on the

unit and insert the power plug inside the PCH compartment.

To turn on the heater, follow the instructions below:

•

Check that the display shows RDY; if OFF is displayed

instead, work on the control, under FUN, and set the

device to ON;

•

Check that the Tin value is higher than the Von value on

the LCD display.

When ON appears on the LCD display, the heater starts the

ignition cycle.

NOTE: Frequently, when turned on for the first time,

the pilot burner cannot ignite because there is air in

the gas pipe. This will lock out the equipment. You will

need to reset the equipment and repeat the operation

until it ignites.

6.9.

Analysis of combustion

Wait until the heater is switched on. Check that the heater is

running at maximum power by using one of the two methods

below:

•

check that Tin input signal is equal to 10 V;

•

from the LCD display, access the REG menu, then use

the Hi and Lo controls to force operation at maximum or

minimum output.

At maximum output, check again that the input pressure in the

valve corresponds to the value required; adjust if necessary.

Perform the combustion analysis to verify that the level of CO

2

corresponds to the figures in the tables in Paragraph 6.7 "GAS

Settings Table"

If the measured value is different, turn the adjustment screw

on the Venturi pipe. Loosening the screw will increase the CO

2

level, screwing it down will decrease the level.

Set the heater to minimum output, and verify that the level of

CO

2

corresponds to the figures in the tables in Paragraph 6.7

"GAS Settings Table". If the values do not match, screw or

loosen the offset screw respectively to increase or decrease

the CO

2

level and repeat the procedure.

NOTE: The heater directly supplied to function with LPG

is set up for G31 gas. If the unit runs on G30 instead, it is

necessary to verify and possibly adjust settings for CO

2

as

shown in the tables in Paragraph 4.6 "GAS connection".