AH-New

condensing air handling unit

APEN GROUP SPA reserves the right to make changes deemed to be required to its products or documentation

54

code HG0310.05GB ed.A-2010

AH

55

code HG0310.05GB ed.A-2010

AH

HG0131.00 A

013

Air orifice plate

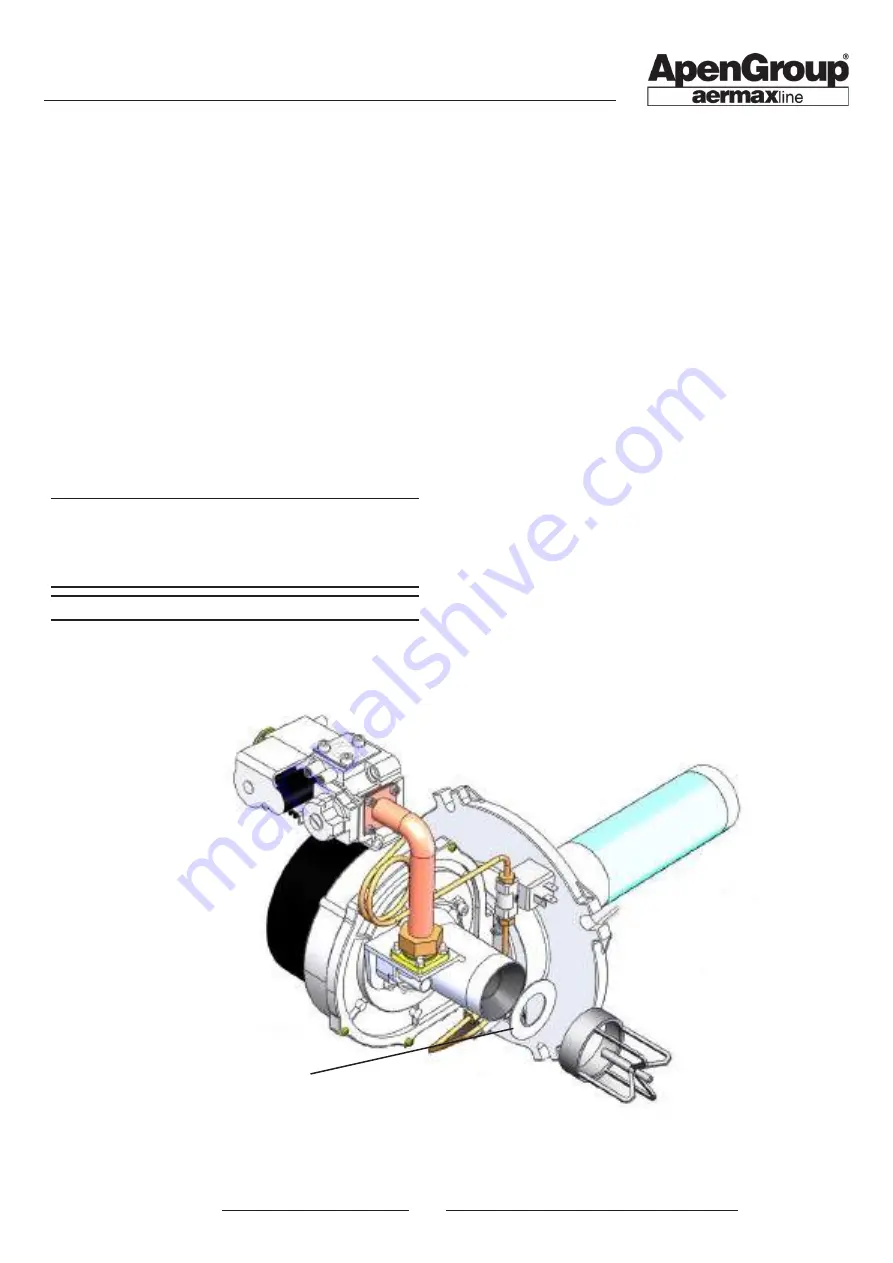

6.12. Conversion to gas G2.350

Conversion is allowed only for Poland.

Conversion from one type of gas to another can only be performed

by authorised service centres.

Conversion to G2.350 consists in:

•

for all models: pilot nozzle replacement.

•

only for models PCH065: mounting a calibrated orifice

plate on the air intake of the Venturi pipe [see Paragraph

6.7 "GAS Settings Table"].

After the conversion, relight the burner and:

•

check that the intake pressure to the gas valve corresponds

to the level required for the type of gas [see Paragraph 6.7

"GAS Settings Table"];

•

check that the level of CO

2

, at maximum and minimum heat

output, is between the values indicated for the type of gas.

If the value is different, change it by turning the adjustment

screw on the Venturi pipe: screwing it down decreases the

value, loosening it increases the value.

Stick the nameplate "Equipment converted for gas G2.350...."

in place of the one that says "Equipment set up for ......".

NOTE: The minimum and maximum heat outputs of

models PCH065, PCH130 and PCH132 are lower with

respect to the operation with G20. Models PCH080,

PCH105, PCH160, PCH162, PCH210, PCH212, PCH320,

PCH420 are not suitable for operation with gas G2.350.

NOTE: The conversion kit is supplied on request

6.13. Replacing the Gas Valve

If the gas valve must be replaced, it is required to proceed with

an inspection and possibly calibrate the CO

2

level through the

adjustment on the Venturi pipe.

It is advisable not to calibrate the offset: the valve calibration is

performed by the manufacturer.

If necessary, carry out the combustion analysis procedure as

described in Paragraph 6.9 "Analysis of combustion".

It is recommended to always carry out the flue gas analysis

after replacing the gas valve.