Maintenance and care

25

Maintenance and care

Safety instructions

Danger!

Never use a water hose or high-pressure cleaner to spray

down the operator or the control unit housing.

Always disconnect the XLR plug prior to working on the door

or operator.

Do not use acids or alkalis for cleaning.

Wipe the operator clean with a dry cloth as required.

Never reach into a moving door or moving parts.

There is a risk of persons being crushed or cut by the mechanism

or sharp edges of the door.

Check all fastening screws and bolts of the operator for tight seating

and retighten them where necessary.

Check the door in accordance with the manufacturer's instructions.

Cleaning chains and operator

unit track

Caution!

The power is supplied via the chain and the operator

unit track to the carriage. It is therefore important to make

sure that these parts are clean and oiled only with suitable

conductive oil. Use Ballistol or WD40 contact spray.

7

8

•

The chain (7) or the operator unit track (8) is very dirty – clean it with

a clean cloth on the inside as well.

•

If necessary, lubricate the chain (7) and operator unit track (8) inside

with a “conductive” oil. Do not use any grease!

Changing the control unit fuses

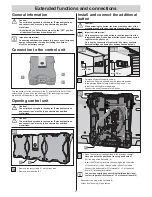

Opening control unit

Caution!

Disconnect the battery units from the control unit.

Pull the plug to the solar module (if necessary).

1

2

3 4

5

6 7

•

Remove the four screws (1) on the front side.

•

Remove front housing (2).

Caution!

First note the position of the plug and boards.

Make sure the board and plug position is correct when

reinserting them! Mixing up the contacts damages the device.

Only hold the outside edge of the boards (6 and 7)!

Do not touch the electronic components!

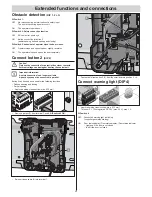

A

8 9

10 1

1 12

7

1

Loosen the guide idler (1) and push it in the direction of the

arrow; fold out the chain guide (2).

• Pull the

fl

at cable (3) plug and the two other plugs (4) and (5)

on the left board (7).

• Remove the left board (7).

• Remove defective glass tube fuse from the fuse holder (9) and

replace. (Type: T 8 A L 250 V)

• Reinsert the control board.

Make sure the alignment is correct.

• Connect the plugs.

• Reattach front housing (2) and fasten.

The fuse of the main control unit secures the door control unit.

• Pull the plug of the

fl

at cable (3).

• Remove the right board (6).

• Remove defective glass tube fuse from the fuse holder (10) and

replace. (Type: T 6 A L 250 V)

• Reinsert the control board.

Make sure the alignment is correct.

• Connect the plug.

• Reattach front housing (2) and fasten.

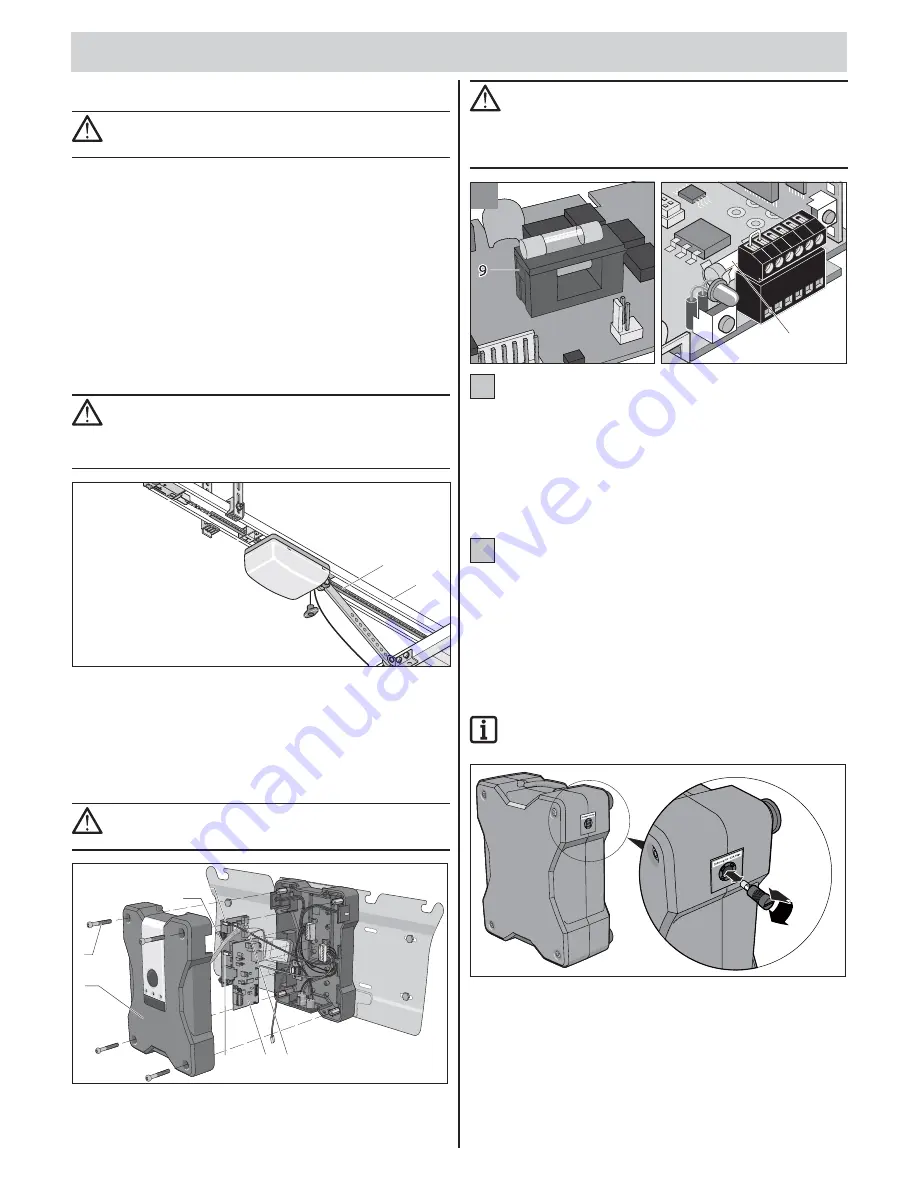

Replacing the battery unit fuse

Important information!

The battery unit fuse secures the discharging current from

the battery box.

The right-hand battery unit is pictured; the left side corresponds

to the illustration.

•

Screw fuse holder on the outside of the respective battery unit

•

Replace glass tube fuse (6 A–6,3 A, slow-acting)

•

Screw on fuse holder

A

B