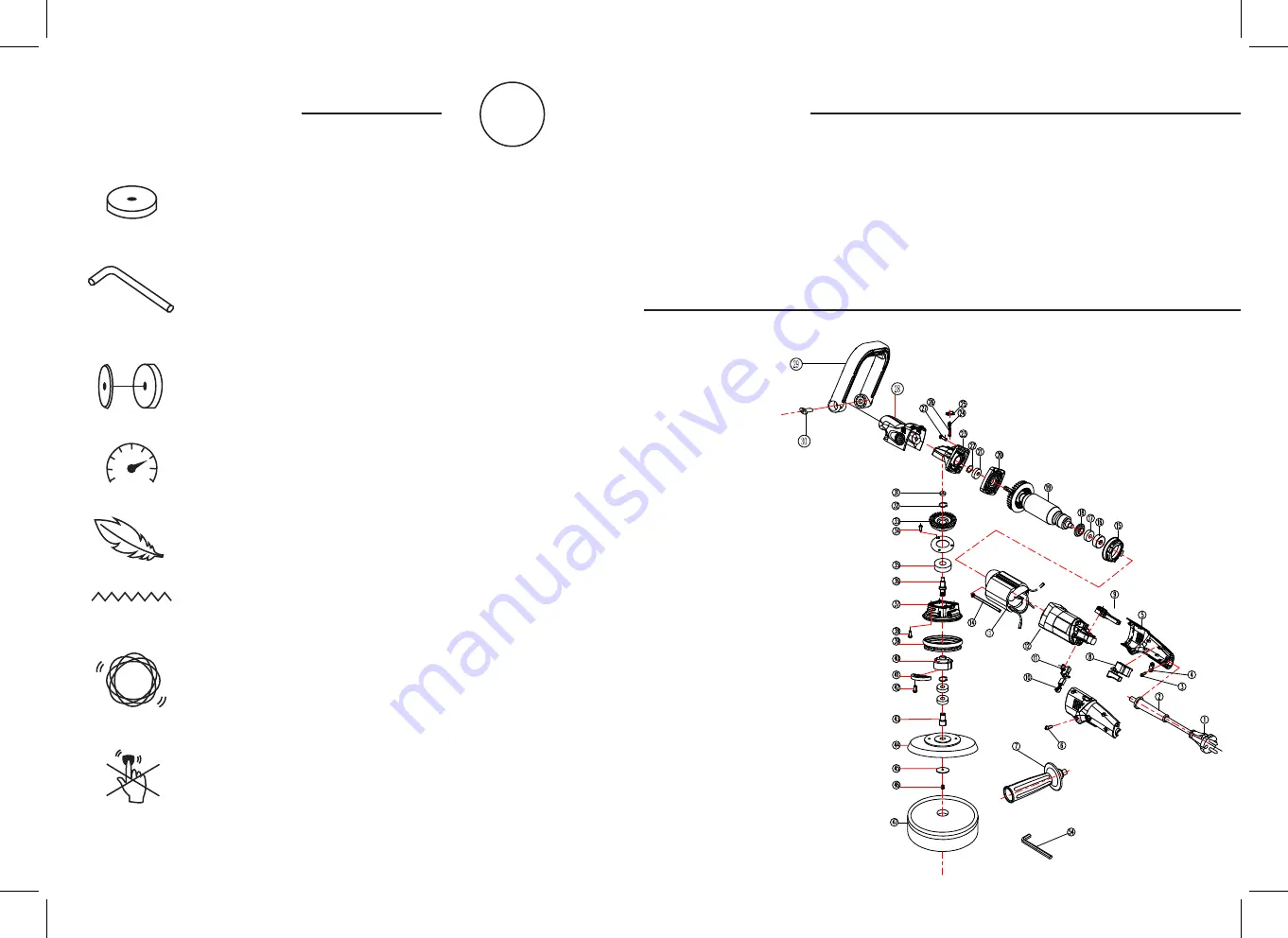

Cable

Cable sleeve

Screw ST4X14

Cable plate

Back handle

Screw ST4X16

Side handle

Switch

Speed controller

Carbon brush

Brush shaft

Motor housing

Stator

Screw ST4X65

Wind plate

607 Bearing cover

607 Bearing

Magnet ring

Armature

Intermediate cover

6001 Bearing

Circlip for shaft O12

Gear box

Shaft lock spring

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1. NEVER start the machine before the

backing pad is installed.

2. Make sure the fastener on the

backing pad fits the spindle on the

machine well and use the Hex wrench

to install the backing pad tightly. If

the backing pad becomes difficult to

remove, use a longer Hex key as

leverage.

3. Align the backing pad with the foam

pad's center. Otherwise, vibration may

be excessive.

4. Generally, lower speeds are

recommended for tight work areas

while higher speeds are ideal for

larger surface areas.

5. To prevent burning through paint, use

very light pressure and keep the

polisher moving constantly.

6. Use the polisher at low speeds while

polishing rough surfaces.

7. For tricky or tight areas, use

"coast-down" to polish. To do so, turn

the machine on for a few seconds to

enable it to oscillate, then turn it off

and use the residual oscillations to

polish.

8. The shaft lock button is for removing

or installing the counter weight set.

NEVER press it while the machine is

running.

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

Shaft lock button

Shaft lock pin

Screw ST4X23

Front handle

D handle

Screw M8X12

698 Bearing

Circlip for shaft O12

Spiral bevel gear

Bearing plate

Bearing 6201

Output shaft

Bearing base and cover

Screw

Rubber ring

Counter weight A

Counter weight B

Screw

Spindle and bearing 6001

Backing plate

Washer

Screw M10

Polishing pad

Troubleshooting

1. If the polisher does not start, check the following:

• Is the power source active?

• Is the power cable on the the machine damaged?

• Are any screws on the switch loose?

• Is the switch or the speed controller damaged?

• Is the armature or stator damaged?

Best practice

2. If large sparks are visible from the side vents of the

machine, the carbon brushes may need to be replaced.

Kindly contact the Apex Customs customer support team

for further information on how to replace these.

3. If the machines become noticeably noisier over time, stop

using immediately and inspect if the bearings or counter

weight are damaged / misaligned.

Parts list

?