10

P2124BA/EN 2014-06

2123b_1_5_en_ bedingt.fm, 03.07.2014

Before initial operation

4

Oils according to DIN 51524 / ISO 3498

4.2

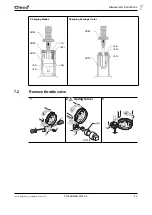

Change air inlet: top / bottom (only on 80PTHHA)

When delivered, the air inlet is at the BOTTOM and sealed with a screw plug. To change the air supply from

top to bottom:

Remove the air strainer from the air inlet at the TOP (do not discard), see 9.2 Pistol grip 80PTHHA…,

page 32, Detail

X

.

Remove screw plug from BOTTOM. When doing this, counterhold with wrench (WAF 17).

Seal the air inlet at TOP with screw plug in accordance with specifications.

4.3

Connect the tool

Connect the tool to the compressed air line.

Maximum screwing-in torque = 40 Nm. Reaction torque at flat end. Counterhold with wrench (WAF 17).

Activate compressed air: 620 kPa in anticlockwise rotation.

Regulator

To attain constant work results, the working pressure must be

kept constant for every individual tool.

Lubricator

Compressed air requires a small amount of oil and is orientated to

the air consumption of the tool.

Calculate the time (

T

) between two drops of oil and make the

following settings at the lubricator:

F

= Factor for pulse shut-off nutsetter = 4

L

= Air consumption of tool at idle m³/min

(see performance data for pulse shut-off nutsetter)

Order no.

Packaging

unit

Liter

Name

ARAL

BP

elf

ESSO

INA

Mobil

Klüber

SHELL

933090

2

HL32

Aralub

EE 100

Energol

HL 32

Polyelis 32

Olna 32

Nuto

H 32

Hydraol

32A

D.T.E.Oil Light

Vactra Oil Light

Crukolan 32

Molina 32

Molina 22

CAUTION!

The air hose can come off by itself and whip around uncontrollably.

Shut off the compressed air before making the connection.

Device

Explanation

T

60

F

L

-------------

=