2123d_Reparatur_en_bedingt.fm, 03.07.2014

P2124BA/EN 2014-06

25

Assembly instructions

8

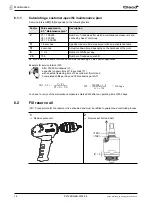

8.1.1

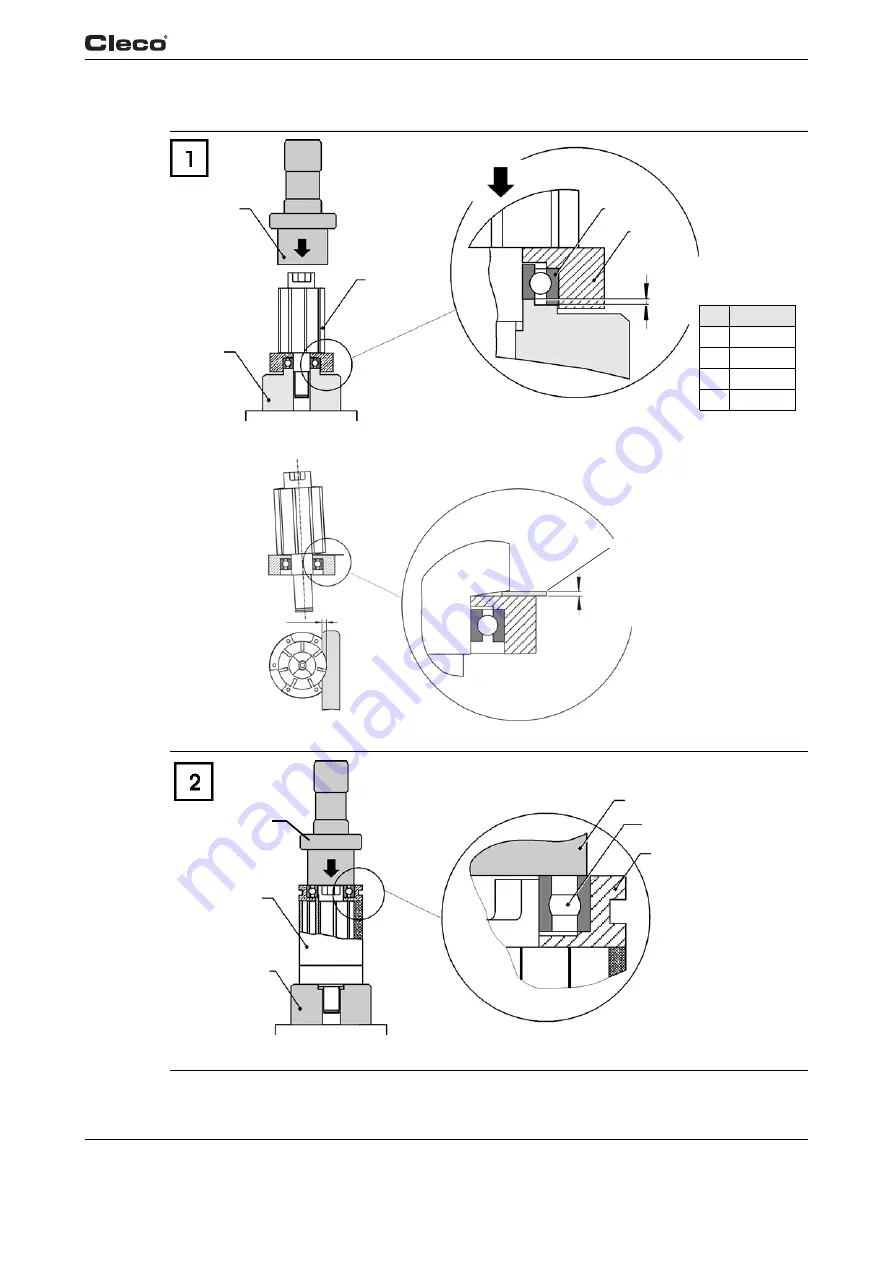

Install rotor cover

1. Press <59> in with

<C4>

, see

X

.

2.

Examine Y

with thickness gage. If dimension >

Y

, step 1 with support

<C5>

,

<C6>, <C7>

repeat.

Press <61> in with

<C8>

.

<C8>

<59>

<C4>

<C5>

<C6>

<C7>

X

<54>

<55>

X

Base

0.02

<C4>

0.03

<C5>

0.04

<C6>

0.05

<C7>

Thickness gauge

= 0.05 mm

max. 2 mm

Y

<C8>

<C9>

<61>

<56>

<60>

<C8>