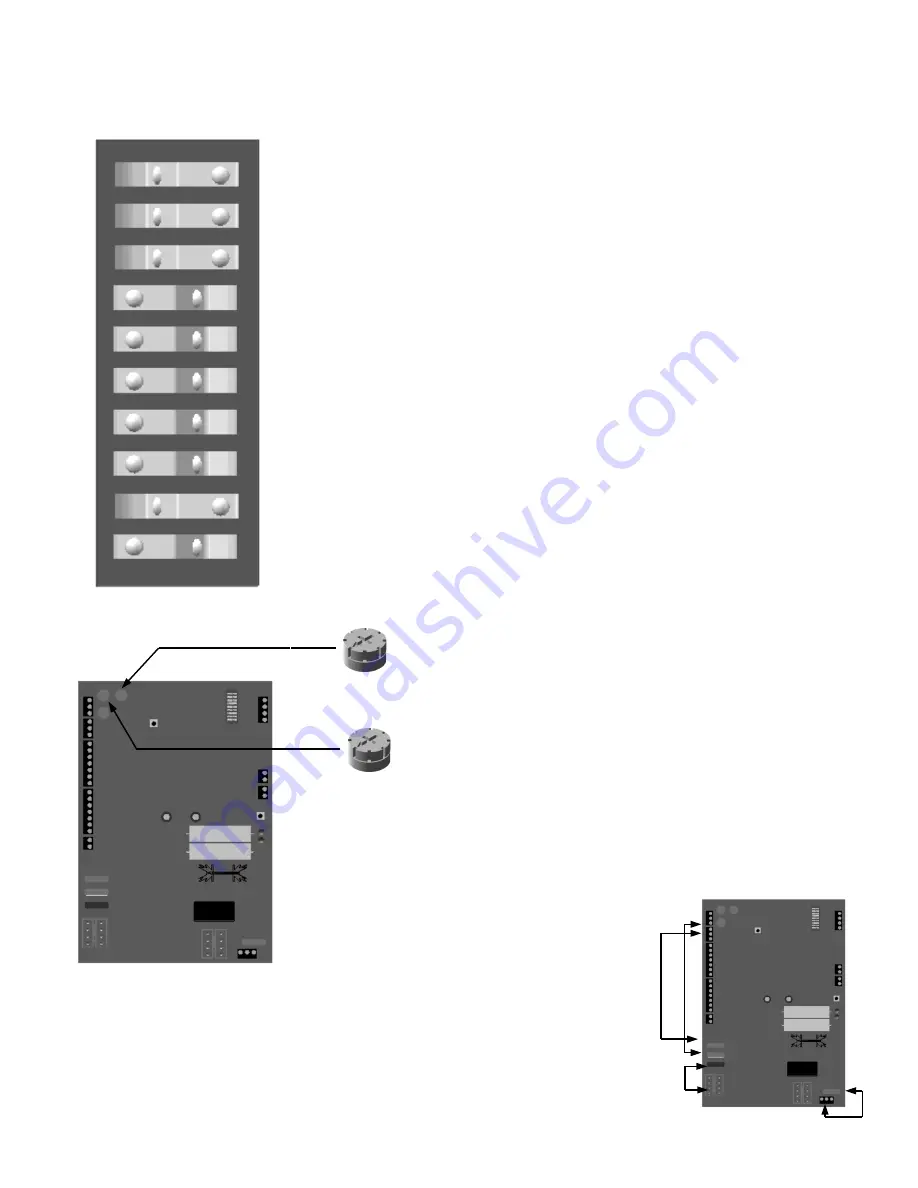

833/834 CONTROL BOARD ADJUSTMENTS

PROGRAM SWITCHES

Factory Description

Setting

#1 ON TIMER TO CLOSE -

Automatically closes gate

ON - Close timer enabled

OFF - Close timer disabled

#2 ON TIMER TO CLOSE OPTION

ON - Timer to close works only when open limit switch is activated

OFF - Timer to close works from any open gate position

#3 ON SLAVE DISABLE

ON - Slave side of board disabled (Used for Single Gates)

OFF - Slave side of the board enabled (Used for Dual Gates)

#4 OFF SIREN DELAY

ON - Siren output is active for a 3 second delay before the gates move

OFF - Siren output is active and gates start immediately

#5 OFF 3 BUTTON ENABLE

ON -

Enables the use of a 3 Button Station

OFF - Disables the use of a 3 Button Station

#6 OFF LOCK TYPE

ON - Output for lock is normally 12V when the gate is closed (For Magnetic locks)

OFF - Output for lock is 12V during open cycle (For Solenoid locks)

#7 OFF COAST ENABLE

ON - Coast feature enabled (delay before motor brakes)

OFF -Coast feature disabled (relays open immediately)

#8 OFF FREE EXIT OPTION

ON - Free exit input will open gate on open and close cycles

OFF - Free exit input will open gate on close cycle only

#9 ON LEARN MODE

ON - Controller is in learn mode

OFF - Controller is in normal operation mode

#10

OFF

INTELLIGENT ACTUATOR ENABLE

ON - Controller is connected to “Intelligent actuator” (816E & 816EX)

OFF - Controller is connected to slide gate or other type of actuator

TIMER TO CLOSE ADJUSTMENT

(When Switch #1 is On)

Rotate clockwise to increase time before gate closes.

Rotate counter clockwise to decrease time before gate closes.

If program switch #2 is on, the gate must activate the open limit

switch in order for the timer to close to operate.

AUTO REVERSE SENSITIVITY

The 833/834 circuit board automatically sets the current sensitivity.

The Auto Reverse Sensitivity can be adjusted while the 833 control board is

in Learn Mode.

Rotate clockwise to decrease the percentage of the current draw.

Rotate counter clockwise to increase the percentage of the current draw.

WARNING: The AUTO REVERSE SENSITIVITY will automatically be

adjusted to prevent injury in the event of someone being entrapped in the

gate. This feature should be periodically tested to assure proper operation.

Refer to SAFETY PRECAUTIONS.

CLOSE

TIMER

AUTO

REVERSE

SENSITIVITY

Fuses

There are 4 standard automotive type fuses on the 833/834 circuit

board. The EMERGENCY BY-PASS plug is protected by a 15 Amp

fuse. The remaining three fuses (one for each of the 12 Volt outputs)

are 3 amp.

3 Amps

3 A

m

ps

15 A

m

ps

OFF ON

Note: The Auto Reverse Sensitivity is only adjust-

able while the control board is in “Learn Mode”. Re-

fer to page 14 for more information on “Learn Mode”.

13