Page 7

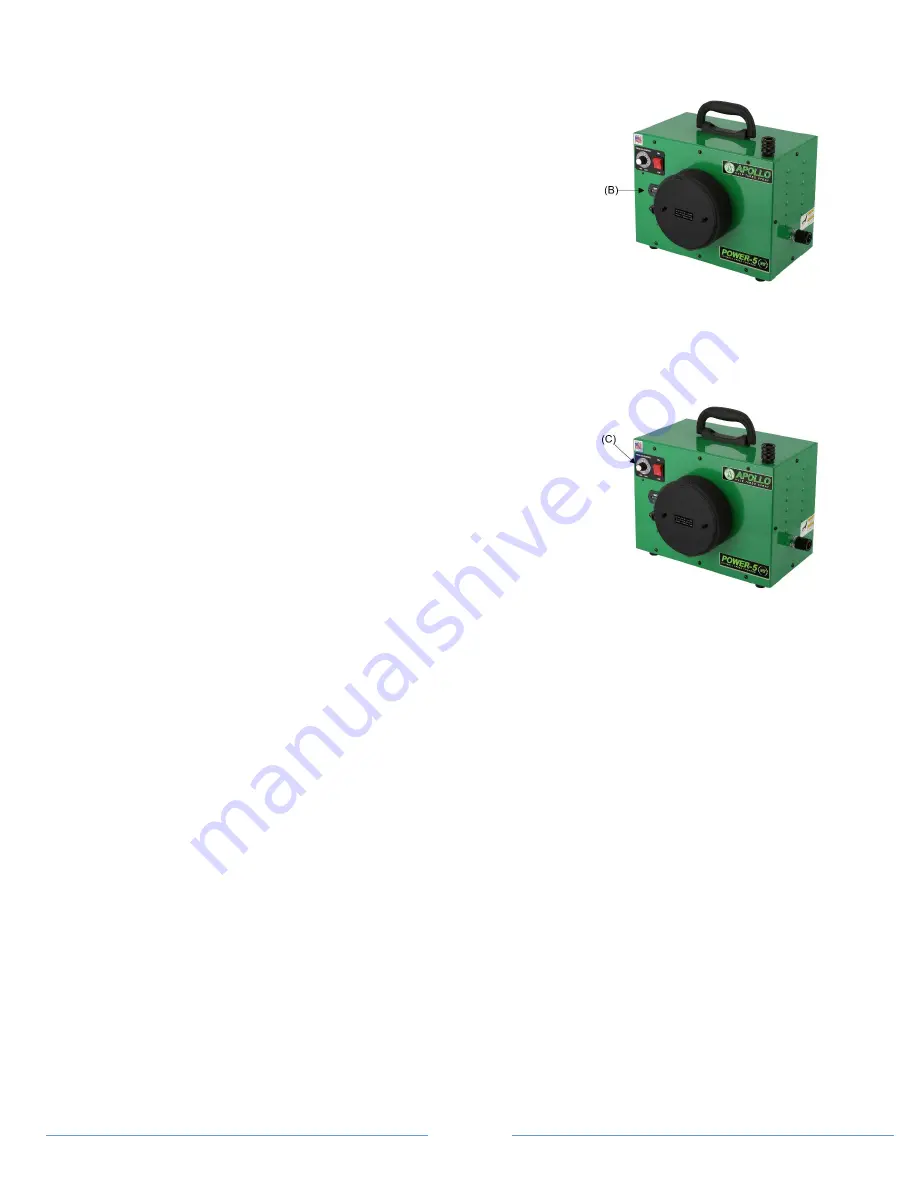

Hour Use Meter

All Power Series turbines are fitted with an hour use meter (B). Use this

meter in conjunction with the Record of Turbine Maintenance at the end

of this manual. Using the hour meter will help you maintain your turbine

better and keep your system running in good condition.

Variable Speed Motor Control (VS)

The POWER VS Series turbo spray systems integrate a motor speed

control to enable you to control your atomizing pressure. To change the

pressure, rotate the dial from left to right to increase the pressure and

from right to left to decrease the pressure. The graduation marks behind

the knob do not indicate any particular pressure achieved. Do not use

these marks to replicate pressures as they will not always relate

depending on the temperature and length of use. It is always best to set

the pressure by doing some spray outs with the material you are going to

spray. Adjust the pressure to use the lowest amount of air pressure to

achieve the best atomization with that material. Check your spray pattern

for even droplet sizes around the edges of the spray out. Once your

particles are all the appropriate size you should get good results.

3 Apollo HVLP Turbines

Each TrueHVLP™ Turbine Unit offers the finisher a maximum operating pressure. This pressure is determined by the size

and output of the unit you have selected. The maximum available pressure will have a direct bearing upon the viscosity of

the fluid that you choose to spray. Atomizing pressure and fluid viscosity directly relate to the efficiency of the equipment

operation and the quality of the results that you will achieve.

The available air volume and pressure at the air cap of the spray gun will meet the delivery of fluid coming out of the nozzle

to create a fine mist called atomization. This mist travels directly to your work piece where it blends together to form a

connected wet film. Achieving a smooth, level surface will depend on the proper relationship between available atomizing

pressure, the viscosity of the coating being applied and the properties of the coating and the size of the needle, nozzle and

air cap used.