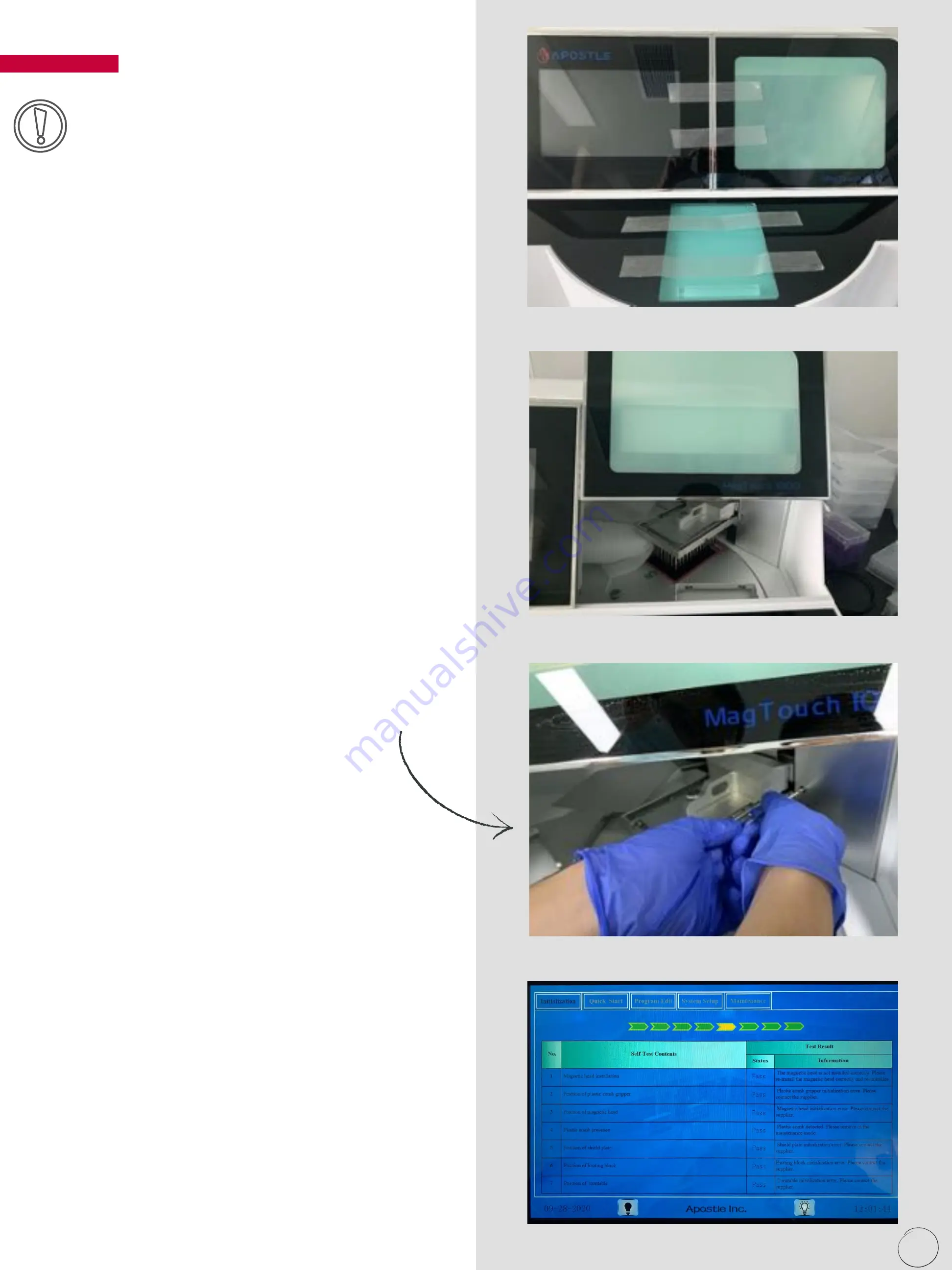

4. Use a 2.5 hex screwdriver to remove the

transportation fixing screw. Keep the

transportation fixing screw. (Figure 3)

03

3. The chamber of the MagTouch can be accessed

by sliding up the right-side window. Turn the knob

on the bottom right of the window to stabilize the

window in place. (Figure 2)

Who We Are

Installation

1. Select an area for your MagTouch that is clean,

stable and has an electrical outlet nearby. Remove

your MagTouch and power cord from the shipping

box and place on the designated area.

2. Remove and keep all the tapes and foam

cushions used for transportation. (Figure 1)

Do NOT connect power before removing the

transportation fixing screw.

5. After removing the transportation fixing screw,

connect the power cord to the electricity and

turn on the machine.

6. Once powered on, the Apostle MagTouch

system will automatically go through the

initialization process and examine the hardware

and software. Wait for the machine to pass the

initialization self-test. If any part of the self-test

fails, fix it according to the information shown

on the screen. (Figure 4)

Figure 1

Figure 2

Figure 3

Figure 4

>

>

>

>